by watanabe masanori 3 years ago

191

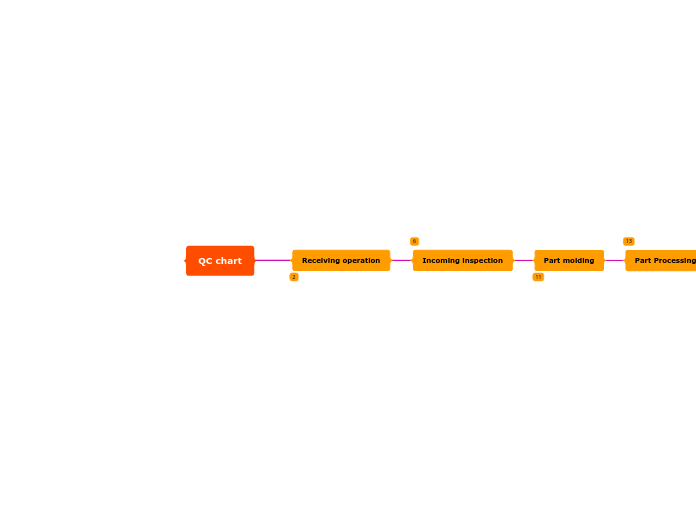

QC chart rev2

The provided text outlines a detailed quality control and manufacturing process for assembling medical products. It begins with an incoming inspection where resin and purchased parts are checked and sampled based on the Acceptance Quality Limit (