door Ewelina Pomian 3 jaren geleden

164

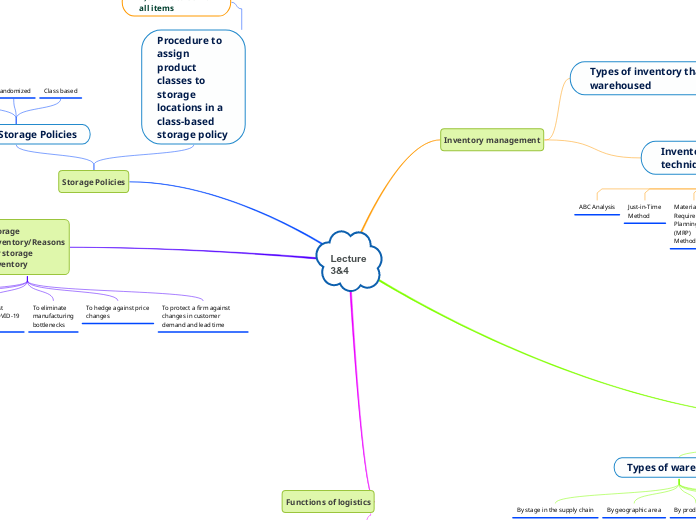

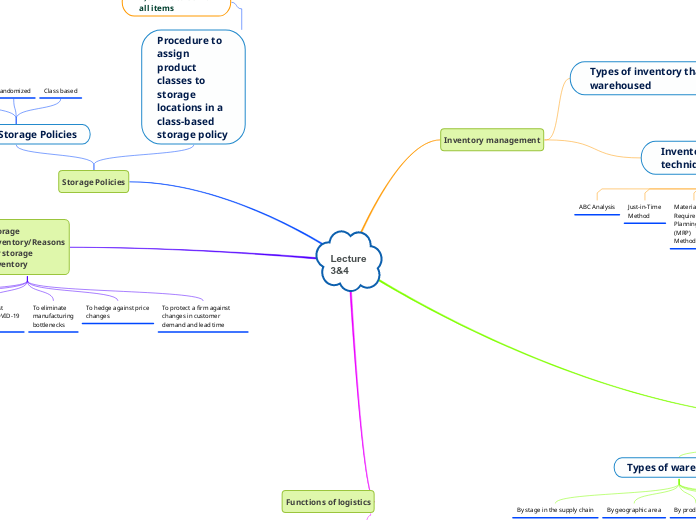

Lecture 3&4

Logistics involves several key functions such as order processing, inventory control, warehousing, transportation, material handling, storage, logistical packaging, and information management.

door Ewelina Pomian 3 jaren geleden

164

Meer zoals dit

3. Warehousing

4. Transportation

5. Material handling and storage

6. Logistical packaging

7. Information

2)Sort items in a nondecreasing order by their COIs

3)Allocate the first item in the list to the storage spaces that are nearest to the input-output

Order picking is one of the most important activities in warehouses because of its direct effects on customerservice level and warehouse costs !

More than 60% of all operating costs of warehouses are related to order picking

- In discreet picking, a single order is filled.

- In batch picking, a group of orders are filled by one order picker.

- In zone picking, each order picker is in charge of a specific zone of the warehouse and selects items that are in that zone. All order pickers do their work until the order is completed.

- In wave picking, orders may be released in waves (e.g., hourly or each morning or afternoon).

- This helps to control the flow of goods and replenishment, picking, packing, marshalling, and dispatching. Wave timing is tied to the schedules of outgoing vehicles.

2)Inspection and quality control

3)Preparation for transportation

4)Put away

5)Order picking

6)Aggregation of SKUs

7)Prepration for transportation

8)Transportation