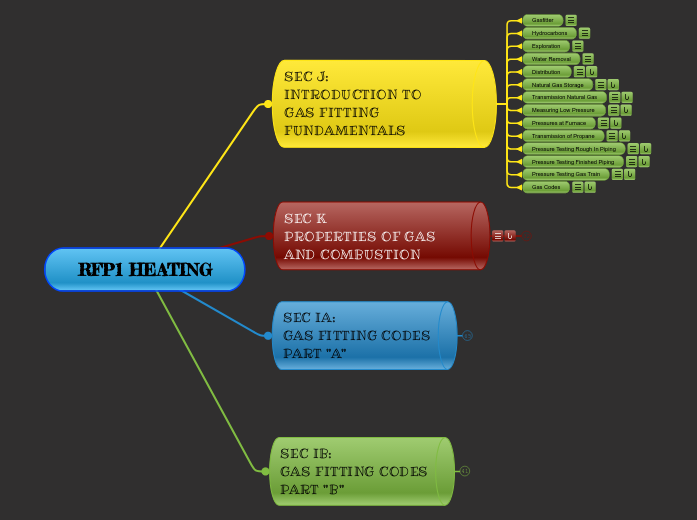

RFP1 HEATING

SEC J:

INTRODUCTION TO

GAS FITTING FUNDAMENTALS

Gasfitter

"B" Gas Fitter - Max they can work on is 400,000 BTUH"A" Gas Fitter - No maximum, except utility and transmission systems.

Hydrocarbons

The basic elements of oil, nat gas and coal are hydrogen and carbon. These are known as Hydrocarbons

Exploration

Gas is trapped in porous formations beneath the earth Seismic animation on the left shows sound waves used to locate oil & gas formations The wet gas pocket that is harvested from the top of the oil is cleaned and refined into Natural gas and LPG gases by Fractionization

Water Removal

All Natural Gas contains Water which must be dealt with or it would freeze, forming hydrates 2 Methods Absorption – bubbling gas through a liquid desiccant (glycol solution) which absorbs the gas Adsorption – pass the gas over a bed of granular solids that attract the water. (ie silica

Distribution

Natural Gas Storage

To ensure enough gas supply throughout winter, Natural gas is stored in salt caverns • Natural gas is pumped in and stored at a pressure of 4100psi during summer and drawn out during winter • Without salt caverns nat. gas needs to be chilled to -258F to be liquified for storage

dTransmission Natural Gas

Pipeline companies (Enbridge, Trans mountain, etc.) do not own the gas, they are contracted to ship it to its destination. • Transmission pipelines run at 300psi – 1500psiWhen local utilities receive gas from the gas processing plant: • They drop the pressure to 2psi – 80psi at the “City Gate” • Natural gas and Propane have an odorant, Mercaptan, added to provide an odour to them so they can be detected as they are colourless and odorless without

dMeasuring Low Pressure

Gas pressures are measured in psi for higher pressures but given in W.C. (Inches of Water Column) for most residential and appliance applicationsA column of water 1” square and 12” high will exert a pressure of .434 psi11 psi = 28” WCOnce the gas reaches your house, the utility company reduces the pressure again down to 1/4 – 1/2 psig (7” – 14” water column) which is low pressure. Residential houses are allowed to have up to 2 psi in the building supply piping

dPressures at Furnace

Transmission of Propane

**Important**1st stage regulator drops pressure to between 5-10 psi2nd stage regulator drops pressure to 11” wc Manifold pressure is also set to 11” wc Propane runs at a higher pressure than natural gas because it is heavier and harder to push through the pipe.

dPressure Testing Rough In Piping

All meters, appliances and regulators detached All outlets closed and capped or plugged. In other words... disconnect everything and only pressure test the gas line

dPressure Testing Finished Piping

Pressure Testing Finished (Connected) PipingThis is done when everything is hooked up.Testing Finish Piping Min. 10 minutesMax. test pressure = working pressure only Test using manometer or smallest dial on gas meter Connections tested with approved leak detector

dPressure Testing Gas Train

Testing Valve Train (Manifold Piping) Appliance burner must be operatingConnections tested with approved leak detector

dGas Codes

SEC K

PROPERTIES OF GAS AND COMBUSTION

CALORIFIC VALUES OF LIQUIDS (NOT GASES)BTU PER POUNDCALORIFIC VALUES OF GASES (NOT LIQUIDS)

d