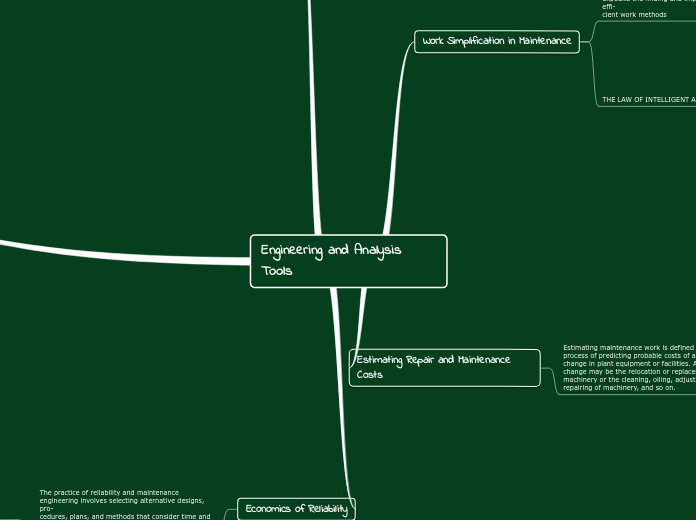

Engineering and Analysis Tools

Economics of Reliability

The practice of reliability and maintenance engineering involves selecting alternative designs, pro-

cedures, plans, and methods that consider time and economy restrictions in their implementation.

Relative Importance of Reliability, Price, and Performance

The wealth of data about customer behavior, values, beliefs, and attitudes often confirms reliability

as the most important product quality attribute, and by that, its impact on the value in exchange,

expressed by price, and value in use, expressed, for example, in terms of users’ return on investment.

Work Measurement

Standardization of Crews.

One of the common complaints, with regard to the performance effi-

ciency on maintenance jobs, is “too many men on the job.

Providing Handling Equipment.

The bulk of the improvements in maintenance work are possible

through changes in handling methods. Maintenance operations still contain much of the brute work

that has been eliminated from production jobs.

Participation with Maintenance Engineering in Measuring Work and Establishing Standards.

Examine the positions of the foremen and maintenance engineers.

Rating and Evaluating Maintenance Workers

GENERAL PRINCIPLES OF JOB EVALUATION

Evaluate all jobs and identify variances from the norm.

Develop the compensation curves based on company policy, competitive rates, and so on.

Make a survey of community and/or industry wage rates for comparable jobs.

Ensure that the plan is compatible with measurement of other jobs in the organization.

Develop and/or modify an existing plan to ensure valid measurement.

Fair and effective evaluation of maintenance workers is the most challenging work of wage and salary administrators and of responsible managers.

Estimating Repair and Maintenance Costs

Estimating maintenance work is defined as the process of predicting probable costs of any physical

change in plant equipment or facilities. A physical change may be the relocation or replacement of

machinery or the cleaning, oiling, adjusting, or repairing of machinery, and so on.

CLASSIFYING THE JOB

result from this position, it is important to have a realistic appraisal of the classifications of work in each individual plant.

This means that the real emergencies must be separated from the work which can be planned.

Maintenance supervisors often feel that all their work is emergency work and that consequently both planning and estimating are impractical.

PREREQUISITES FOR ESTIMATING MAINTENANCE COST

How the estimate will be used is the second prerequisite. Together, these major factors will deter-

mine who will do the estimating, how the estimate will be made, the amount of detail required, and

specific techniques to be followed.

Classifying the job and obtaining full information about its specifications is the first prerequisite.

It is necessary to know the job priority or urgency, work content, and general conditions under which

the work will be performed.

A maintenance cost estimate is based on two areas of information: the type or classification of the

job and the end use to which the estimate will be put.

Work Simplification in Maintenance

THE LAW OF INTELLIGENT ACTION

When confronted with a problem, the intelligence of an individual’s actions is dependent upon his

Capacity to handle the human relations involved.

Ability to perform the tasks required.

Desire to solve the problem.

Work simplification can probably be best described as the intelligent employment of well-established human behavioral patterns to encourage and expedite the finding and implementation of more effi-

cient work methods

The improvements developed and proposed by these “experts” are usually strongly resented by

the prospective users. Their implementation is often resisted, even occasionally deliberately

sabotaged.

Much time and effort must be expended by the “expert” to become familiar with each new activity studied, in order to be sure that all pertinent aspects and interactions with related activities are uncovered and properly evaluated