Embracing variablity

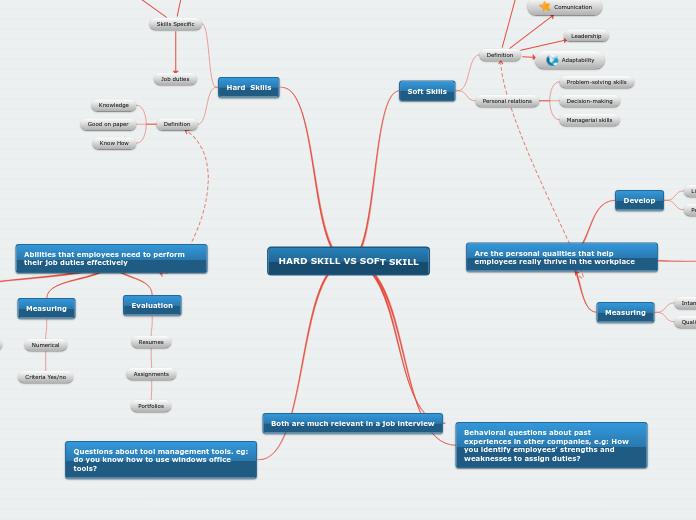

(4) How reduce efficiëntly ?

information theory

corrective action

Kanban

WIP limits

scrum

timeboxing

quickly & aggressively

to make correction matter

only usefull when having cummulative invariants

as IS the case in product development

previous phases influence following phazes

as is NOT the case in manufactoring

effects of invariants are 'reset' between states

probability

in test with

other outcomes (fuzzy)

simply put

maximize probality over all results

3 possible results

33% probality

more complex

binary outcome

true/false

maximul efficiency is reached when probability on true or false = 50%

snow in july in los angeles

near 0 %

snow in dec in denmark

near 100%

binairy search

search by 'zooming' in

is very efficient

why ?

(5) Plan for variability

fix

architecture

modules often too toghtly coupled

DDD

make queues visible

information radiators

but not cost !

show size

practice

sw project managers

don't see the queues

it's information

stocked in inventories

don't know that

planning with 98,5 % usage

only work in a deterministic world

which we are nog living in

is the cause of so much of the delays and unpredictability they encounter

manufactorers

know that

keeping 10-15% slack is needed

to be able to meet expected delvery dates

theory

relation between size of Queues & % of utilisation of queues

queue size goes up exponentially when nearing 100% usage

breakeven

around 85% - 90% usage

cost of queue size

aount of unfinished work

cost of 'slack'

not using 100% of the queues

(3) how to make it less harmful ?

alter the 'pay-off' function

buy info

on unproductive threads

or paths that you can abandon

example:

now change the pay-off function

nothing else has changed

but cost reduced significantly

buy digit for 1€

cost of 3 digit nr is now (on average) 1,11 €

buy 2nd & 3d digit after getting feedback

lotery:

buy number

for 3 €

1 chance in 1000 to win

1 chance in 1000 to pick winning 3 digit number

earning 3000 €

via fast feedback

reduce queues

aka unfinished Work in Progress

minimize lead-time

maximize flow

set WIP limits

aka inventories

in manufactoring world

smaller batch sizes

iterations of weeks rather than quarters or years

®

depends on the total cost

vs fixing

eg: using spelling checker

of preventing

eg: prefect speller & typist

or correct it

(1) variability harmful ?

depends on

Pay-off function

is under our control

needs to be assymetric

which is the case in development

not always

eg: 'options' in financial world