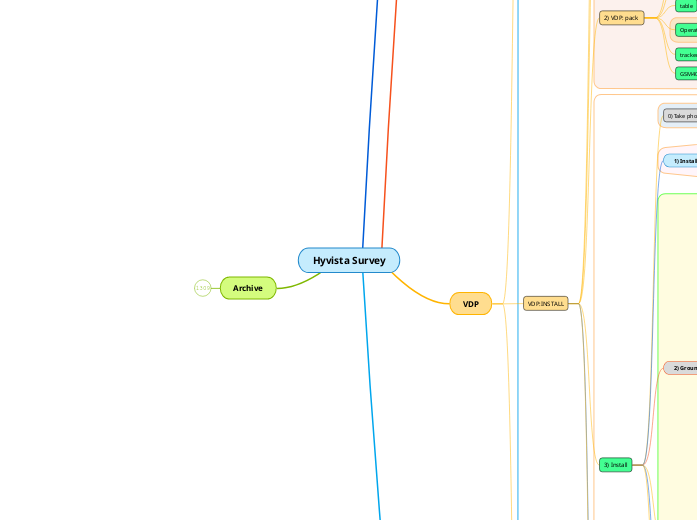

Hyvista Survey

Archive

Done

quote for P1 computer mount

PAC

Request for meeting to discuss survey work, survey engineering, other work

Phone call with Pete.

Expressed that I am "not cheap" :-(

2020 March

Pete email requests if I can replace Steven Star in Melbourne next week.

Unresolved

2020 Jan 28

Send email requeting meeting

Hi Pete,

I have sent through invoices for the last three surveys (VDP_AU_2019-6, VDP_AU_2019-7 and AUS2019c).

The latter two, are post our agreement on the 5th November in regard our discussion on day rate (see below).

When would be a good time to discuss this?

Note I also have expenses for the latter two missions, but I am having a -lot- of trouble with them in Quickbooks. I will submit them as soon as I can.

Sincerely, Glen

2019 Dec

Send email requesting meeting/discussion (in person/phone/email) as previously agreed.

No reply

2019 Nov 05

Pete Agreed on the basis that whatever is agreed upon is back dated.

Hi Pete,

I just got home after another big day...

Thank you for your reply. I am ok to park this until after these installs, as long as you are ok that these installs will be covered by the rate we negotiate.

Hi Glen,

Thanks for the detailed email, there are a lot of points to go through here and I think it best to do that once the dust has settled after the next couple of weeks when the acquisitions programs are up and running.

In terms of "installation/engineering" work for project surveys, if you feel you are not remunerated appropriately then I am open to what you feel is a reasonable rate moving forward.

2019 Nov 04

Said ok to discuss remuneration, with 25% of time on surveys being engineering days, but wait until after survey

Hi Pete,

Further to our discussion this morning; I wanted to discuss some other things but we were not private in the office…

In regard to my rate for operating, I have been ok with the rate for operating on the basis of how it has been in the past. That is, an installation with -some- issues, operating for at least a ~week/5 days then a pack down.

I had a quick look over the VDP_AU_2019 diary and made some quick estimates (attached). I have been away on survey for 65 days. Of those days, 17 days were engineering/troubleshooting/installs. That is 25%!

There were 8 non-fly days, most of which I was still contributing by documenting, organising etc. That is just ~10%.

The week of the platform change over and install in Melbourne was not operating but significant engineering and installation efforts.

I feel that for installation/engineering work that $400/day + $150 day is too low, significantly.

For the platform week, if I was to add up the actual hours worked vs the effective hourly rate, it is a very good deal for Hyvista, and not great for me. Especially compared to the other project Sydney based work I have and am continually postponing to accommodate the survey work and Hyvista’s best interests.

Steve volunteering what he is receiving to be the very same day rate, with only $50/day less in T.A. than what I am receiving. (FYI – we were not even talking about money or anything like that. Classic Steve thing to do.)

In terms of training, regardless of who they are or how component they are, it is -significantly- more work/effort than just operating. It was for Clinton, and it will be for Peter, Will, or whoever. I could not help thinking, ‘I’ll should take $50/day less and do Steve’s job.’

With the complexities of these installations/troubleshooting, having a third person slows the process down. I hope you can understand that. (I can elaborate on that if you like?...)

In regards to the Aubrey installation, by way of fact that it is a new aircraft it is going to be involved/complex; it is inevitable. While I understand your motivation to send Peter down with me, if you want this done fast, then I should go alone. This is my preference - It will give me the full headspace to focus on the one thing. I suggest that it would be better that he be involved with the Hymap install in JAJ, since it is a re-install in a familiar hanger/location.

Also, please understand that while I can ‘sprint’ in bursts, as the days mount up end-to-end, I run out of ‘steam.’ I did my best to keep myself physically and mentally well. That week I ate very healthy; I avoided hot breakfasts, ate only vegetables, fish, sandwiches and did not drink at all. I was trying to do everything I could to optimise my mind and body knowing that it was going to be consecutive days of big physical and mental effort.

I was totally worn-out after that week, and that directly lead to me becoming ill ( am far from 100% now), with wasted downtime. I had other things I needed to do last week, that I had already postponed from the week before.

I also feel that having to pack up in such a short time, was very stressful and risky. You made a comment about being flexible, I believe I have been more than flexible with the countless trips that have all over-ran. With the rushed pack up a lot of corners were being cut. Rushing is risky and can lead to significant mistakes. I just hope that the Vexcel gets to Aubrey safely without being secured properly.

I spent over an hour in the hotel in Melbourne sorting out the tools, and bits and pieces that were -shoved- into my bags, so that I could be prepared by next day for the GAM install. That was on top of arriving at ~10:30pm. Virgin did not serve a meal on the flight other than some crackers. The hotel only had limited food options at that time. I waited an hour for the food only to be told that I had to go reception to get it (that hotels policy). While the hotel had a washing service, it had to be sent out. I washed some clothes in the shower then hung them over the air-conditioned to dry in time. By the time I got to bed, it was well past midnight, to be up again at the crack of dawn to do it all again. It was too much.

I am grateful for the work you and Terry have included me with. And for the most part, enjoyed the survey work and helping grow the business.

A big negative factor has been working with Steve for countless reasons. If he was not in the equation for the last week, things would have been -a lot- better, however, I still feel my point are valid regardless.

I am happy to discuss this when I see you next, via phone, or via email?

Sincerely, Glen

PS - As mentioned, could you please send the boilerplate insurance policy. I am thinking of getting some professional indemnity insurance.

Ear Plugs

google earth

vtc

email: platform

Log sheets (modify/print)

log photos

Buy SSD

Peter

new plan

left to go over

Update lines for ATC

wide lines

Flyer report

run by Pete

TNT

Checkin software

upload mdb file

PC-Software checks for track error?

Dinner

Terry

phone nubmer

hotel extension

Send photos to PL

flyer report

cross track error colour

prints

lines

USA2019a

processing computer

Synology

Dropbox

Credit card

weigh rack

next time

Post USA2019a

Logs

North American Aerial surveys

Tyler (sone of erric)

eric

Nancy

Notes

FBO: PSA Personel

Jason

Brandon

Jennifer

#Weather websites

https://www.eldoradoweather.com/radar/US%20Radars/wxusradars-hanis3.php

https://www.windy.com/-Clouds-clouds?clouds,37.970,-123.311,6

https://www.accuweather.com/en/us/southwest-region/satellite?play=1

#Hotel booking websites:

Expedia

Travelocity

hotwire

#Nexttime_Glen

- bring calibration targets

- Cloth to clean aircraft window

#Next_Time

- Protection box for phaseone

- be able to test photo phase one without pc (or on laptop)

- Great Trakair monitor: Lontium

- wifi on computer

- more usb ports/hub

- Batch warning display

#Todo:

order lougage scales x 2

Preferbly with TAR

>20Kg capacity

- tracker manual: height adjust, track up

#Done:

- Big mouse

- macrium reflect

Display fusion (mirror application, save/load app positions) ctrl-1 [drag window to top of second monitor] [drag window to top of second monitor]

Recommendations

staff

Roy

Eric

Tylor

John Margin

Wife: Nancy

Sandro Lipke (Pilot)

@Home

@End of mission

Fuel rent car

P1 Computer

log out of chrome/GE

@shops

Manderines

Banannas

Laundry detergent

Ginger/ginger beer

milk

Yagult

mylanta

@hotel

@ aircraft

leaver arm

20191101 GEO Presentation

Mexico2019

RS-232

Caddy Error

PhaseOne parts

Setup/test

rewire LEMOs

Vexcel-126 Install

Bunnngs

mini tape measure

laser level?

Plumb bob

Gloves

Clean lens

lens cleaning kit

Ivo Mol

02 6021 2929

mb 0428 262 032

tools

Monitor

Vingette Angle

Power budget -35Amps

VDP_au_2019

air sickness

@Travel

read manuals

drift control

review leaver arm procedure

Power Budget

Installation procedure

attach plate to platform

Mount Platform to plate

Inspect Photograph boxes

double check inventory matches

camera system

empty plane

@Home_Prepare

verneers

clear tape

head lamp(s)

battery extender

Do

Hotel room

Charge Tablet

Look at software

keyboard?

leaver arm mausrment

ruller

square

laser levels

fix cad

check sm3000 drawings

wrap plate

cut notch in plate

Power cables (splitter box)

Swing clearence

Blocks

trackair on my laptop

Large paper

plumb bob

extra lasers

one drive share

C-SASS meeing @ UTS

AUS2019c

John

Photos

CAD

GPS Cable

Bring

luggage scales

laptop

micro SD card

Documentation

Operation

In the hotel

FileExtractor

copy data from SSD

Hyamp SSD

Refilling

Burns

skin

eyes

Hymap Installation

Power

Connections

Camera hole

Previous aircraft install list

To check

Door

commond

Plate

FOV

Things to coniser when installing

C-SASS

reply/thankyou to Gule@Applanix

Test Flight 1

Assess the data [1W]

Test Flight Actual

packdown

Install [0.5d-1d]

Ground Test

Take photos for reporting

Run SeqGrab, check frame grab and save to file ok?

Set camera to frame rate and window size with writen C# MicrovistaCFG

IMU

recording to log file ok?

GPS reception ok?

Measure leaver arms, enter into IMU [2h]

Install 2 x GPS

Pre Flight Preparation

Pack

[0.5d]

Prepare Test flight procedure documents [0.5d]

Required flight line recording/repeats

Log sheet with each recording, filenames etc.

Dark current recordings

Line 1,2,3

Send flight lines/flight plan to [1h]

C-SASS partners

Pilot

Flight Date

Weather

Flight Paramaters

120knts ~60fps

Location: Javis Bay

coordinate with C-SASS partners (TDC)

Ground targets?

Co-fly with exisiting drone?

Plan flight lines (TDC)

camera angle

height

location

Lab Setup/Testing

Assemble complete system in lab and test [3d]

C-CASS developed software

SeqGrab (record flight line frames)

Hypercal

Microvista configurator

Sapera Image Library

Visual Studio

Windows10?

Hardware

Boot firescan computer-working?

Assemble firescan computer into firescan or similar rack

To Procure

targets

SVHS extension cable

rack to mount test computer? (can we use something already on hand, such as the firescan rack)

3.6V power supply for Microvista

make one from LM317 etc.

ebay?

Lemo connectors?

Tasks

Focus

DSLR

Sony vs Nikon?

Sony A7

Camera lens FOV

if true, hoz is 51.4 degrees, vert 40 degrees

maybe measure? 1h

from web diagonal is 63 deg

Make 3D proxy model [3h]

Much higher resolution

Nikor 28mm FOV

A number of lenses to choose from to select appropriate FOV to ~match MicroVista spectrometer (Hyvista/Glen)

From memory was very close to 60 degrees to match Hymap

Effort done on this could be used in a Hymap+Camera survey in place of the PhaseOne, or made into a backup kit that could be sent with PhaseOne.

Look to have all the cables needed to ingest GPS on hand in lab

connect up/test [2h]

nmea input from IMU cable

retreive/assess cables [1h]

Already 3D modelled [0h]

either

Propose intervalometer mode

just run with battery power?

A7

current batter good?

spare battery available? pac?

D810 ok, spare batteries (mine)

assume both cameras have, but need to check the required cycle time, and number of shots is possible 1h

Displayfusion setup

Laser(s) to check stability of mount

Set window

Specral (lasers)

Dark (1000 frames at frame rate)

Halon (1000 frames)

Design mechanical installation [4d]

DSLR Mounting [3d]

3D print [0.5d]

Design Mount [0.5d]

2 x GPS install

bolt through GPS mouning style?

On PAV30?

Camera hole details

possibly inspect aircraft at Newcastle if details are not available (hopefully not)

photos?

dimensions/drawings?

Calibration [TDC/GH] [1d]

Use integrating sphere with neon lamp spectra to align spectrometer and calibrate wavelengths

Assess adjustable mount stability [GH/TDC?] [0.5d]

Check how susceptible the mount is to knocks, vibration by

For finer check, compare before and after saved spectra images (in say Photoshop)

watching image spectra in Hypercal while applying mechanical stimulus

IMU/Frames Data [?]

Methods

IMU 10MHz divide down (100,000) to 100Hz

1PPS upscale to 100Hz

Asynchonous/interpolation

Frame grabber clock runs indepedantly

IMU logs time stamped position/latitude at 100Hz to text file

IMU runs independantly of the frame aquistiion

Discuss with TDC

Select Test Aircraft (Newcastle) [TDC]

Mostly done for Charlie's 404

Can

fabrication of floor plate

PFH/RP World

Spectrometer Mounting

plaform-PAV30?

As a spacer

For stability?

Mounting rails to plate/frame?

2 GPS Antenna - check!

Look up Tristyn etc.

GPS app to send location

Trackair

Schedule plan

---

Car phone holder/charger

Oscilliscope

offline files

printouts

Take

tripod(s)

sprare phone

3d mouse

bubble levels

headphones

Toolbox

soldering iron

chalk line

headlamp(s)

wifi adapter

Order: Terry-Digitkey order-dI/O connector/backshell

Animation

Dove Prism Version

Hymap2-Computer

Remove last mission’s data, including PhaseOne images <– check with Pete?

Add labels (rear GPS baud rate, Klau, ethernet ports, cables) <-GH bring in label maker.

TChart License install

3D model add laser and mount to Ronin DJI

Fit laser to 3D print

Ultimaker 3D Printer parts

WOL computer

Follow up email: Spectrometer CAD model

wol address

3D printer suppliers

Report Terry

Measure slit

Test with Integrating Sphere

Peter Makredes

Belt for sander

Integrating sphere distance?

Shutter

Refine design for Filter thread adapter.

modified lens: No

Diaphram Shutters with C-mount? No

Large 3D printer

Slit size

Thought to be ordered

12,25uM

Current? - measure

travelling microscope typical resolution of

0.01mm=10uM

Gyrostabilized platform Assessment

3D model?

Mass

3D printer assessment

Look at local suppliers

3D print proxy model of spectrometer

3D print main body

3D Print Lens

GPS not working on IMU?

Just needs more time to init

IMU communicaiton

log with RS-232

get IP working again

shutter-test

Trigger shutter

Digital IO

add connectors to cable

label cable

tidy up shutter code

Hypercal - ability to write real-time frames to disk

Setup high frame rate

Communicate with Camera

Stobe->Evenit in (IMU)

Connect Frame Stobe to event

CAD model of install

breakout board

parts

IMU mount

Camera/lens model

Serial comms with Microvista Camera to configure window, frame rate etc. as it is volatile and the config program only work with windows XP.

Add to Hypercal

WORKING!

Image Grab

IMU data writen to txt file, or image metadata

Frame saved to file (tiff)

Command to request IMU attitude?

Pashr - IMU position

IMU Time

Code GPS/IMU read

Message processor

Message parser

Interface

Ethernet? Serial? USB?

Slit-Change

adjuster stability

HyperCal

-Foton Focus Camera - test with recommended software

Fix Hyper call to work with different resolution

Fix grid positions-check at start of program

Handle hypercalconfig missing, or not read

error message

set to defaults

adjust x and y max depending on camera configuration - not needed.

grid: frame rate, exposure - not implemented. hide ui elements

Save image data

Dark current/bright frame

paramater: #of frames to average

format

BMP etc.

text

Area

Development

Mouse window area

MouseClick Event

Look at/Test current save code

AOI

whole image

Saturation Warning

Highlight saturated pixesl

paramater: #pixels over threshold for warning

paramater: Threshold level

Other

Fix closing hang

rename HyperCalD->HyperCal or other?

Make stand alone exe so anyone can run it, with installation/installation instructions.

Tool tips

Save as dialog box

Add autoscale/full scale to spectral cal plot

Fix Control Designer error

Make robust

shutdown background threads still running and crashing.

Spectral cal inputs

Alignment: Spectral

Gaussian Fit

Alignment: Spatial

-done

pixel bar

toolbar

save image data

save to xml

fastline

real time display

Curve Fitting

Fix graphs not updating properly

Calculate centre X value

account for DC offset: not needed

spatial band

Mouse move line

help file?

Installer

New Log sheet

Check list

set timer 3 hours

record 500 line hymap line

Headset test

Spares/Backups

spare cable set

MEP/Trigger/NMEA

Headset 1: new cable replacment: sent away: 20220528: eta 1 weelk

therepro 2 x USB-c cables

Nice to Have

PDS

Rojone

Cameras

remove foam

teather software

Deployment SOP insturcitons

Nuc

offcie-excel

< PeterC licence

Feild Laptop

All Hymap software

Image Backup

Spare Nuc?

spare fuse

spare USB disk

-nice to have

LED indicators for MEP & Tigger

shorten power cable

spare cables

power

data

travel/road case/box

Surveys

Champion Reacquire AUS2023b_r3

Computer

Osprey in UJU

out

Bunnings

tape dispenser

long screws

timber

Prepare/To

any printouts?

Key for truck

Install guide

ultrcam

remove platform

remove antenna, replace with tear dropped shaped ultrcam antenna

hymap de-install

Cable joining

bolts/nuts

side cutters

crimps

crim tool

video mount

Table

packing tape

clipboard

From hymap1

video splitter, VGA, USB extensions cables

mouse matt

Survey

Take?

spare phone

QM2000.NET (or prime)

Mood lights

Photo editor (travel box)

travel monitor

name tag

drink bottle

headphones (charge)

email mum & dad itinerary

3d mouse?

International Driver's license

head lamp (charge)

photo copy wallet

skiplagged.com

travel toolkit

spanners

alen keys

screw drivers

pliers/cutters

shifter

Cloath

Forensic rullers

https://www.legear.com.au/3-part-folding-scale-metric

https://www.dojes.com/scenemarkers.aspx

https://www.safariland.com/products/forensics/crime-scene-documentation/rulers-and-scales/3-part-folding-scale-metric-F_101.html

IN-AUS2022a

--done-2022-pre_Canada

Google Sheets offline/Excel

travel case data

Klau uSD/USB

Samsung T5 disk

Hymap SSD

NUC backup

D810 bolts/fasteners

--done-2022-AUS2022a-Alice Springs

Procure

Straps?

LN2 DG approval: GAM

trailer hire

procure

extensions leads 2 x 30

M8 bolts

length

funnel

Span#2 mount fit to Hymap2 test

Number of Dewars

UJU has more room, so should be able to fit more

check (GH)

as much as possible

setup google sheet - project

include table

pilot display ram mount

Check power outlet: checked

GSM4000/Ultracam sent back to Hyvista (pac)

Fasteners

Find ours

SM4000 to Plate

5/16 x 4

hymap to SM4000

Rack mounting of PDS

ask GAM for screws

power connection

Power connectors-utilux

aircraft power

SPAN-CPT

Motion test of SPAN, in trailer?

fedex back Hymap2 SPAN

PL

TDC

Testing configure (TDC)

Finish Dewar pump down

spare table

Vaccum Pump Dewars

Pilot Display, wire up DC power, test (GH)

Packing list spreadsheet (TDC)

not needed, no shipping

LN2 Supply

BOC Gas & Gear-Alice Springs

Contact

Phone: (08) 8952 4922

Open ⋅ Closes 4:30PM

Address: 57/59 Elder St, Ciccone NT 0870

Pre order? (TDC)

'Steve' Generally have a tank but run out and then has to be trucked in from Adelaide. Advice is to check ahead and if need be they will order re-supply.

labels

Hymap detectors

log sheet/folder

Terry List

--done'

(1) check the usb connections from the host to the SSD receptacle

Suggest test flight plan would be to fly a couple of lines with the HyMap01 Span and then (in flight) replace it with the HyMap02 Span and fly a couple of lines. Leave the HyMap02 Span on the HyMap for the survey.

(9) There are 3 ssd caddies. I think one needs formating but all should be checked and clean.

(8) Run FlightGUI and check if the correct date is shown on the GPS (there will be no INS info but should show "alighning")

Make sure you pack a GPS cable to go from the rack to the antenna in the aircraft

(7) Is the INS indicator LED flashing (on the front of HyMap)

(6) Using Engineering, check that all arrays are functioning nominally (note; there is one non-functioning detector is both SW1 and SW2)

(5) Cool down the dewars (as you would on survey)and note how they behaved (fast/slow to cool etc, How long they stayed cool)

(4) Reconnect all cables (don't use roof antenna and rojone)

(3) attach the SPAN (originally from HyMap 1). Screws are on the top of the laptop near the MS257)

(2) put the lid on (better with two people -- less chance of accidentally knocking the dewars)

Backup disks - order?

Lee

clean of Hymap disks/computer

Clear off old data

Test

Eric heads up: GAM

GAM: headset

waiting on

Test drift control, remote control software

usb-a cable

Imrpove/Sort Tool box (GH/TDC)

tools to remove span

electrical tape

tie down hardware

toughbook?

install tracker if time

Get

order: nuc rack mount

farnell order mill strain releif- not enough time

make

Critical

Canda2022

D810 Klau1 MEP cable

D810 run through & document, with Glen

2023 Peru Prep

Spare Hymap Cables

earth cable

bunddle label

Tracker dongle mount

fix pilot display VGA connector

Test A6D

Klau Cable

Hymap recroding issue

Peter Lovenfosses' Notes on Hyamp SSD

Peter Lovenfosses' Notes on Hyamp SSD

Tried 500GB T7 samsung SSD, plugged in at end of USB cable and straight into host. Same DMA error as Hymap SSD.

Plugging in 250GB USB, worked without issue for 2 days.

USB Connector

Peru Vaccines

Rework tool box

Hymap2: PDS: Pilot display monitor VGA connector repair

Print Log sheets?

Find spare Hasselblad USB cable, or order new one

Spar NUC

copy tracker lines to Hymap2, backup

backup HymapBAK-NUC

install tracker

backup Hymap2-NUC

reimage

Test (45mins)

Install Survey Software

install camera software (1.5h)

hyocus

phocus

install Hymap sofware (copy) 5 mins

Hymap SSD (30mins)

erase

gather

PhaseONE

replace short USB 3 cable

--done:

active long usb cable tested

ordered, waiting on

re wire MEP/NMEA cable for new Klau

if time: Test removing red

Spare NUC, change ublox baud from 4800 to 19200

Electrical tool box - review

D810 - take as backup-yes

packing list ->TDC

PACK

Peru Power adapters?

Check/Test headset

batterie

---done

locate all headsets

UJN?

Spare Hymap Cables: use Hymap1's as spare.

Precharge oscilloscope

Make new klau trigger switch

Make spare kalu tig/mep breakout cable

Update P1 diagram

Borek air

arrange twin otter, nato to our headset atapters

ram mount ball-assume there is one packed or they can get one

New Ops computer

setup software

PAC Order

New Spare Hymap Cables

Jumper Hymap pds power

Hymap1-done

bundle up

add ethernet

--- post packup/send---------------------------------------------------------

202306xx_HyCAM Tamworth

-- can wait

Blank plate for no camera

Setup SPAN-CPT #3

configure

Log events (check Adam email)

change orientation

Connect to Klau and test

Trigger with MEP

receive MEP-Done

Insall glass window

cut glass

cut gasket

clean metalwork

ultrasonic bath

Mechanical Fit

Run cables through Hymap

Test software

Infinity Focus

Cables->make robust

20230713_RedEye

Experiement design

Prepare step-by-step list

flight actual

Experiement log sheet

prep prior to flgiht

charge batteris

2 x USyd

1 x hyvista

assemble and test all equipment

site planing

Tracker planing<-(PC,PL)

site locaitons

GH<-GAM<- minimum conforatble speed for UJN?

altitude

O2

>14,000

12,000-14,000 longer than 30 minutes

Spares/backups

Batteries

Charger

Todo: Charge prior to flgiht

SSD

Naif: Means of inflight data/sensor checking

Naif: Remote desktop, VNC etc.?

Mounting of spectrometer in can

Can we fit in 2d camera (e.g. Hycam?)

Fix bolts to platform

fixed bar

make compatible as fall back

gimbal

Lab test

Design of spectrometer to gymbal mount

3D print gimbal to can mounts

can gimbal work in vertical orientation?

Feild trip form/insurance

Survey: Gunnedah/WA/Redeye

Make Radcal Tests

sort

Tool boxe

oscilloscope

Consolidate

mark green

aircraft power connection tools

utilux connectors/crimp tool/nuts/bolts

spare headset?

from UJU/Dave/Steve?

GAM?

already pumped, 2nd pump?

Order Jim

Data/NUC

Test/check Hymap SSDs

Backup disks

load tracker flight lines

Clean off

Wire out Hymap1 data to alow for external USB

Aircraft UJN

Organise suport with agair

Aircraft power check

Drill/tap screws into UJN plate

<-TDC/PC

Sites

Platform Mounting

Redeye can mounting bolts

take taping capabilities

<-GAM

Wire up Klau on/off switch (1.5h)

wire up monitor power

wire up Klau power

Wire up PDS to gan 3 x +Aircraft power togehter (1.5 hours)

Calibration<-TDC

re pump down?

Wire up external USB access like Hymap2

Peter L

AUS2023a_part2

Install

do

check spare SSD and hymap reader

Train Peter L

document as go

return bolts to Steve

processing laptop

Processing laptop

Data Disks

Hymap reader/disks

Spare inverters

tool box

other ?

Klau

Hymap1

Prepare

Install into Hymap1

test Klau

Test HyCAM on different PC

External disk mod?

capacity to do in feild<-take USB3 extension cable (home) GH

Test AOI

Tracker files: PL

Pilot: PL

Move to airag (240 ground power)

let airag know

Gosford area:PL

--Done

PhaseOne

baud rate

error

Update PhaseOne Firmware, CaptureOne <- Pete says no.

PhaseOne GPS Lemo – re-terminate ground return wire. A little long. <-GH

Install bigger 4TB hard disk <- TDC to supply

Hymap noise investigation

Document

Repair cable

Hymap 5V

Pool

Detector Manufacture

Project Design Goals:

Latent Goal: Update make spares for current 32 Channel Hymaps.

Keep things as similar to existing designs as possible.

Helps make components universal between 32, 36 channel and 40 channel design.

Helps reduce different components to manage (manufacturing variation)

Change brings risk to unforeseeable consequences in performance or otherwise.

Deliverables

4 Day

Project Timeline

Report

Budget

Project Operations

Services

Materials/Components

recommended contingencies

Layout vs parasitic capacitance

Silicon vs swMCT

New swMCT array performance vs inference form silicon.

PCB layout development

If it takes and extra design/manufacture teration to get a layout that ac hives the right feedback capacitance.

Not meeting spec?

limits

time limit on estimates

limitations

risks

Procurement

3 Days-parallel

Other?

Microscope/camera

Software

Altium PCB: Just get the current license to work

Solidworks: Update

Setup/gear-up

0.5 days

Setup flow hood/tools

Time to find and setup Detector bench testing setup

Detector Build Assessment

Components/Materials: Manufacture/Supply Lead Times & Co$t

Items

Simple Quote

1 week-parallel

Connectors: Flex interconnect

Omnetics

PCB Components

Components

Capacitors

Gold

Inks (Lord)

Substrate (Corestek)

Fuzz button shim

Indium Solder/Flux

Fuzz buttons

Kovar/Invar material

@pfh

FR-4 insulator material

@pfg

Mylar blanket

Black Paint

Epoxies

Assess current stock level and expiry

O-rings

Complete Quote

2 weeks-parallel

Cold filters (not needed?)

Make new test PCBs?

Test PCB are used to break out the preamp and postamp boards for bench testing.

Dewar Connector

Dewar-50pin

Cold fingers

Flex circuit

Can thicker flex be used<-Dewar Connector pin pitch vs track thickness?

3D design update design

Lead times

Email/phone quote cycle

Review previous vs promised, vs new equotes

2 days

Mechanical

Fabrication:

If not find alternative

o0ver 5 days-parallel

Check Paul Fahduley is still available for manufacture.

Design updates

5 days

Coldfinger (and possibly base mount) modifications if preamp needs to be expanded in size.

Modify Dewar Connector Mounting for new dewar connector.

Coldfinger modify for bigger 25 way (vs 21 way) side flex connector.

Arrays

Modelling Performance

Use existing Mathcad models to model:

Frequency response

RMS noise @ postamp

Offset

Signal to noise

Delivery Schedule

import/Export licenses

Manufacurture->IntSpec

Manufacture->China

Find out specifications

? Day

Physical Size->Preamp Dimensions

Photonic/Electronic->Preamp Circuits performance

PCB Component Loading

Investigate IntSpect buying a bonder and doing bonding in-house

Also look into Precision circuits for manufacture, since they list wire bonding as one of their capabilities.

Investigate Melbourne Centre for Nanofabrication with consulting from miniFAB for bopard loading

Calls

Background

Nanomelbourne.com

<10Km (8mins) from miniFAB.

miniFAB

One possibility is the miniFAB could be consulted to either advise MCN with this or maybe do it at miniFAB.

The part that was somewhat special, however, is to do with the indium soldering/flex finger bending etc.

Regarding the work vs your/miniFAB’s specialist project-centric knowledge, most of the work was straightforward and would transfer well. While needing to check the documentation/logbooks, however, you feel that it was well captured.

He suggested that Melbourne Centre for Nanofabrication (MCN) (http://nanomelbourne.com/) could do the work.

miniFAB: The company has grown, and they have moved away from this type of work. Apparently, there is not even a wire bonder in the lab anymore.

PCB Manufacture

over 3 week period-in parallel

Ring Precision Microcircuits

Assess

visit?

3 days

emails

calls

Files/tooling from Hybrid on hand

Availability

Capability

http://pml.nz/

Rob Carruthers (General Manager)

Assess what files we received from Hybrid Electronics

36->40 Channel assessment

Compatibility 36 vs 40 channel

0 days -in passing

Using a 36/40 in a 40/36

Flex stiffeners

DB 50 –(influence on)--> Dewar mechanical design.

Postamp to Mil – there are 4 spare tracks on the postamp flex

Mechanically

Internally – coldfinger, coldsheild, dewar, spider parts

External – swap detectors

Flex

1 day

Flex: Preamp->Postamp:

21 way -> 25 way: there is room: OK

Flex: Postamp->Mil Connector

can thicker flex be used<-new dewar connector

thickening of power supply tracks

adding extra 4 tracks

Postamp

Flex Connector: 51 way: 4spare pins: OK

Room at bottom of PCB for another opamp: OK

Preamp

It will be hard to fit another opamp on the current pcb size/layout. Possibly moving the bypass capacitors down and the main Gnd track up will make space. Alternatively the PCB can be increased in overall size. The board could be extended vertically, until its clearance impacts on the dewar base. There appears to be scope for modifying the base to accommodate such and increase. Similarly the PCB could be extended in width, which would require the coldfinger to also increase in size, and also possible effect on the dewar base.

Expand preamp permiter to make more room.

Fit another opamp on current size/layout?

Dewar Connector:

Change from micro D51 3 row hermetic connector to alternative. The current connector is very difficult to solder the flex to with three rows, and prone to cracking. The alternative could be Dsub50 (if not too big), or perhaps micro-d D51 2 row.

Impact on dewar

overall size, and potential fowling in insturments

will fit

search/evaluate alternatives

Previous Issues

4 Day

Thicker power cables to preamp/postamp.

Need to check the mods that were done, to see how that might affect the power/GND cabling. Possibly need enamelled wire separately.:

Cables

Postamp-(Gnd)->Preamp

Mil connector-(+/-v/Gnd)->Postamp

Mil connector-(+/-v)->Preamp

PCB: Postamp: Thicker tracks, big GND

Flex: Postamp to Mil (thicker tracks)

Channel-negative cross-talk

Add ground layer to prevent negative cross-talk

estimate effort to verify theory that postamp ground resistance is causing the issue.

Using silicon add extra ground wire(s) to postamp. Compare crosstalk pre and post modification.

Using existing Hyvista S36 dewar for testing

1 Day

Refundable deposited on safe return and performance meeting spec before loaned.

Interconnect cable detector<->Chinese Scanner

Add temper seals

Add safety precautions (protection diodes), fuses?

Make cables/connectors

Intspect Test and verify performance:

PeterL

tidy rachet straps box

Ask peterC about USB portable backup disk

Setup field laptop as Ops backup

A6D

Phocus 3.3.6

check GPS metadata

Hyphocus

D:\Software\!_Commercial_Software\TrackAir\01_Tracker_Hardware Lock_Driver

copy software

D:\!!_scratch\Glen\HYUP-FINAL

Ethernet

specific IP setting

D810

open soruce tething program<-Glen

--next time

IXA180

IXcapture

Testr Headset/Batteries

u-bloks: baud rate setting percitant

Training: Cro, RS232

Clear out Hymap SSDs

Toolbox -sort/consolidate

Palletes?

Assess what we have?

Repair?

Audit

GSM3000 fluid

ATC Inconsistencies

HYMAP

Next time

6) De-install

Headset-remove batteries

Radcal test

5) Operating

Make spectral target Radcal Tests

In-aircraft kit: equipment/spares/tools list

Oscilloscope: portable

RS232 debug kit

rs232 converters/tester

USB to rs232 cable

Tool box

Data disk kit

Backup NUC

remove lens cap

Take photos

aircraft empty

camera port

general fasteners

2) Pack

Feild laptop

disks

disk reader

telstra dongle

logsheets/clipboard

ground power supply

spare nuc

hymap

hycam

headset/extemnsions

LN2

trolly

Funnels

big

small

dewars

Lens cleaning kit

multimeter/osc

tool kit

saftey equipment

glasses

gloves

hi-viz

aircraft bolts

PDS->aircraft

hymap->platform

platform->aircraft

GPS antenna

long cable

silicone/gasket

Ram Mounts

2 x extension leads 20m

Airplane

Aircraft

higher oild consumption; enough oil packed?

maitance schedule/hours?

water

HF radio/spidertracks

ILT/eperb

Hymap

runs

load tracker

Hazelbrook

test GPS tracker

Data

provide operator with flying specs

HyCAM

Photobase

equivalent photo interval

Altitude

L/S

speed

Disks big enough for data?

Clean of

data disks-SSD

Hymap Disks

Oops computer

Hymap NUC

delete images

shipping

Packing List

SLOI: Shipping letter of Instruction

Commercial Invoice

Ground power supply: change voltage?

charge oscilloscope

Airtag

check pilot display ram mount etc

Log sheets

clipboard & pencil

print

Check headset

batteries

NUC

NUC->Google docs offline

copy file structure

tracker survey lines

backup image

dataraid

away usb disk

clone to spare NUC

Order LN2

LN2 planing

trade off with weight vs endurance

How Many Dewars?-> # of Shipping Box

Liquid Nitrogen local supplier?

Jim

Check aircraft power location/connector

Calibration

radcal

TDC Calibration Training

5) Spectral Calibration

Save to file: naming convension: SWIR2_HY02_Date

If effor during scan, choose 'retry' rather than ignore (will get out of sync)

Background slope

can drift due to physics changing, e.g. temperature of slit, dewar cooling

Settings

Averaging: Mdium - for general, got to High, for lower signals such as tails of VIS and NIR

detector: Swir2

Step: Medium: 2nm

Grating #1 and #2 only work

Detcal

Print previous spectral calibraiton

looks up wavelength, and +/-50nm

Looks for detecor channels

96

65

Careful with fibre bundle

Start with sw2 (2 x diffusers)

4) Software dir hyup

Mirror alighment

3) Setup Colimator to Hymap

Start with SW2

Lamp+2 x diffuser

optional O-ring

DC power supply

2) Check dewar bolts are tight

1) Test Gradings

no scew (rotation)

signal is peaked

spectral

Bright Call Lamp Compare

pump down dewars

Aircraft time

50h

in feild?

what equiment needed

100h

Contacts

aircraft

pilots

send tracker primer

company

email/phone

GPS Tracker-working

Test, register

new travel cases

criteria

brighter inside?

easy to see

hard case

Hymap disk reader

longer bolts for WB57, ~8mm

Feild Laptop<-new

Condor install prepare

take

extension leads

print labels

prepare/check

survey actual

test site

away bag/kit

multimeter

telstra modem

check bolts

get

Ram arm

SSD/USB

Return O-135

Missing nav computer box

already sent back with previous ultracam

fix screws/tabs

Missing cover plate

could be missing with bolts.

PAC says vexcel has it?

spidertracks

ATC Logging

what was said

who

supervisor

phone

time

Daily logs

Wx links

template?

lkns to

logsheets

sop

Peter L-AMSL

new for each state

UJN install

SSD for quicklooks

5G

pack airtags

USB3 cable

Timetable

Thursday

contact GAM

headset

label

TNT courier slips

mechanical penciles

USB3 extension cable

slack post, video transmission software

document install

Clone O-135->O-103

Backup time ~20 mintues

Used Samsung T-5 1TB (mine) to backup disk (all partisions)

set boot disk to USB first in Bios to boot Macrium

Clone Software: Macrium reflect 8 (from my USB Key)

Reply NAV computer

VDP:INSTALL

5) De-install

remove airtags from FDUs

packed roadcases

road case content

Ultracam Uninsall

Check of parts/serial numbers vs receive documents

Photograph all parts

Check all aircraft storage areas for Hyvista equipment

Seat Pockets

Rear, Nose, Wing Locker?

Retreive GPS Antenna!

Print of Part List, pencil check off

photograph->pdf->dropbox folder

Retrive ram mount

4) Test Flight

Airplane fueled

3) Install

Install Documenting

Installation Checklist

Phototgraph, post in slack

Installer(s) - including GAM staff

install date

Inventory-UC Delviery List

Photograph, post in stlack

Notate

Who

Date

Location

Camera O-xxx

4) Take Photos

Copy to VDP/Installs dir on dropbox

Installation-All

location of platofmr USB cable

Serial number plate

Coverplate

photo of location in back of aircraft

FDU Labelled

Serial numbers

Camera Serial Number

TODO enumerate

Lever arm setting

3) GSM4000->put USBA-USBA cable in operator kit

this is for connecting/controlling the GSM4000

2) Ground Tests

Test headset

Log headset number in GS diary

Software installation checks

Chekc clock and data set to Zulu

Nav/Tracker Computer

Ultrcam

Lever arm

photograph/record before/after

AV-POSView

IMU/GPS OK?

COS

Platform

FMS

Install Airtag

update Diary GS

Label each FDU

Ultrcam/Ultranav Ground test

Tracker lines-Add

remove camera cover

store in back of aircraft

apply Label "O-103"

1) Install Camer & Platform

Add airtags to FDUs

Log airtag number vs FDU number in VDP diary

Apply lable/stickers

FDU number

Hyvista Address

Platform -serial number-

Ground wire

aft-port side corner

GSM3000: Left-right

GSM4000: Diagonal

Platform Roadcase x4

Ultracam " O-103"

Photograph

Camera cover

On Nav Computer

On Camera Control computer

On FDU door, text pointing foward

Camera Roadcase x4

0) Take photos

System Screen in Ultrcam

to tracker COS etc. version

IF new aircraft

GPS antennal/location

power/gps connections

camera port: in details

outside

inside

include tail number

2) VDP: pack

GSM4000

USB A-A cable

the one comes with, for contingency of platform issues

tracker lines

Operator Kit

FDU SHIPPING>

Courier Slips

Box & packaging for sending FDU

knife (standly/retractable)

Tape despenser

Lens Inspection>

Lens Cleaning Kit

Lens cleaning fluid

Lens wipes

foam pad/sheet

for lying on the ground under the plane

Inspectin mirror

Hyvis Vest

Telstra Modem

charge

HEADSET>

cable ties / small

Headset extension cable

Batteries in Battery (4) holder x 2

Headset

TOOLS>

Extensions leads 20m x 2

for ground power, need to be long to reach

Electrical Tape

Multimeter

spare battery

COMPUTER/IT>

Mouse Matt

Power converter-24V-12VDC

Pilot diplay

Ram mount

ram ball on aircraft?

ram arms (long/medium)

monitor/vesa > ram ball adapters

video cable long

USB-C>HDMI converter

power cable

connector

aircraft spacific

cigarette lighter?

USB disks x 2 (fast/fastish)

lanyard

Nav Computer

Mounting

Ram arm Long

Ram Diamond>Ball adapter

usb hub

mouse

Keyboard (narrow)

Ultracam Camera

USB3 extensin lead

for PFP USB transfers

Ultrcam Computer

Mouse

Keyboard

USB exension lead/USB hub

LOGSHEET>

pencils/mechnical x 2

eraser

spare leads

string

log sheets

folder

INSTALL

IEC cable AU, for GPS

Airtags for FDUs x 6

log itag # vs FDU#

Foam sheet for GPS gaskett

12V converter

cigarette connector-cable-pilot display

Power connector to aircraft

aircraft bolts

gps antenna

gps antenna gasket

Tools

power cable wiring tools

cable ties

heatshrink

crimp tool

screws/nuts/washers to join

Utilux connectors kit

drill/drill bits

1) Prepare

Aircraft Spacific

high oil consumption

Contact Airag etc. of install schedule

test all our spares, hookup

Ground wire?

bolts

wire

Tracker lines (test light, actual)

Test Flight

Wx??

Fuel-Airplane

table

Mounting for

nav computer

Ultracam computer

get previous lever arm settings

itags

Print-labels

FDUs

FDU#-back of fdu

FDU#-roadcase

Hyvista

Camera Cover Plate

platform

serial on rear/left corner diagonal

Controllers

x2

Ground Power Supply

x3

x1

road cases

x5

0_ Next time list

Ground wire, check?

VDP: Operater Procedures/SOP

Operator Job Description

On no-fly days

training

HyMap

first aid

project

documentation

maintenance

hardware

software

Princples

Dress code

In Aircraft

cap / beanie

warm jacket

sunglasses

On ground

Hi-viz vest

closed shoes

long pants

Hyvista polo

efficency

safety

communicaiton

VDP task specific

pilot hand over

Pilot have email footer with their contact details

Procedure

Request for a verbal hand over to new pilot

make sure the aircraft is fueled

ATC early

ATC conversation is logged

tracker

Windy WX

Maps

kml

pdf

Communication

Slack

PRINCIPLES:

Use @ only for gettng peoples attention.

Running commentry, with no @ of people

make post readable/stand alone

e.g. pilot/John

Keep topics to one daily aircraft thread

Updates

Travel Updates/posts

accomodation

Location/dates

commerical flights

Arrival airport: time

Departuyre airport: Time

Flight number

Respond in a timley manner.

Updates only @ people, if their attention is needed otherwise, don't for record/inform

Principles

take photos

weekly report

Survey Day

post flight

Next Day Plan

?

sites

dispatch FDU's

Map making

email to pilot

check maps

Slack Post

flyer form

Site complete Checks

Photograph Tracker Coverage

Flightlog

record aircraft 50 & 100 hourly times

during flight

Camera Operation

Exposure

Nav computer

mdb

Camera

0) pre flight

pragmatics

? hotel checkout

pack snacks / lunch

equipment inspection

lens inspection

aircraft inspection

Pilot comms

ATC Call by pilot

Wx assessment vs AOIs

Day Before

pilot

aircraft refuelled

AOI options

Generate Maps

Send to pilot

Generate AOI maps /generate_ATC_map [slack]

weather options

IN

Waiting on

GAM

UJU/UJN GPS antenna anchor nuts/cable

UJU seat rails

Spare NUCs (GH) ordered 20220831

TDC ordered: Long GPS Cables: a few weeks

Order hand spool

Headset: replacement earpads ordered: 20220528 eta 1

USB & retainer clip

2 ordered 20220530, eta this week

Buy

AU suppliers

Hasselblad?

Test data recording, if Klau is powered off.

Send to PeterC to check

Workshop Tidy

VDP equipment

IT Cables/Connectors

Pilot Monitors

Headsets

Documents

Bolts/mounts

Runnway approaches vs survey maps

ifr charts

Info

GAM hire minimum 30 hours flying, on a month by month basis

vdp-graz@vexcel-imaging.com

--lower

--depricated

installs

monitor centred for pilots

Operator tables-standardise on a power connector

UJU and UJN have different power connectors to power the 12V connverter. Add a common power connector, so the tables can be interchanged.

VDP Kit

done

foam for inspection

mirror

Mutlimeters

https://rapid-tech.com.au/extech-ex355-true-rms-multimeter-ncv-temperature/

Subtopic

Tubs

carry handle

wheels

clear

Large Monitors

Materials

mount

ram bolt/plate

ram arm

ram vesa

officeworks

cables?

hdmi two output

2nd big monitor

UJN

Pliot Mount to the right-correct

Headset #?

Floating power outlet

Big monitor, but nav computer at front

UJU

Pilot Mount to the left-needs to be moved to the right

Asked DAN/GAM

Headst #3

double seat

Needs bigger monitor

pilot primer

--

Windy

wx overlay

Sun angle

work backwards to get on line by

fuel day before

fuel-if 2nd operator, don't fill aux all the way

Tracker Tutorial

video?

screenshots

ATC comms

Call 6:00

with the view of you will getting up

Send all maps the day before

Standard ATC email for pilots

Tracker

remove lines

background maps?

Glen

--done

Leverarm

SOP

--done-pre Canada

Print new log sheets

sync dataraid

Klau smalll stickers

check camera mount in CAD/previous, mount to plate?

Hazelbrook Testflight lines

fix

Tracker line removal?:

London

VDP

2025-04-09

Planing lines

Global mapper/QGIS

SnapPlan

Lee's SOP

Operations

__done

return O2 bottles

Return gas bottles?

VDP diary/flyer form

insall snapplan

Pack C-101

Located near door for pickup.

Wrap and strap

put in C-101 (photograph)

retrieve GPS from O-103 pack

O-139 tracker remove old projects

reprt in slack @ peter

key

alarm

Monitor for desktop

AOIs Planning ahead

Peter C

Wx