Technology Reshaping Supply Chain

IE Business School

Master in Management - Sept 2017 Intake - Section 3

Operations & Supply Chain Management - Prof. Felipe Quintana

Betty Yunlei Lu

Technology Reshaping Supply Chain

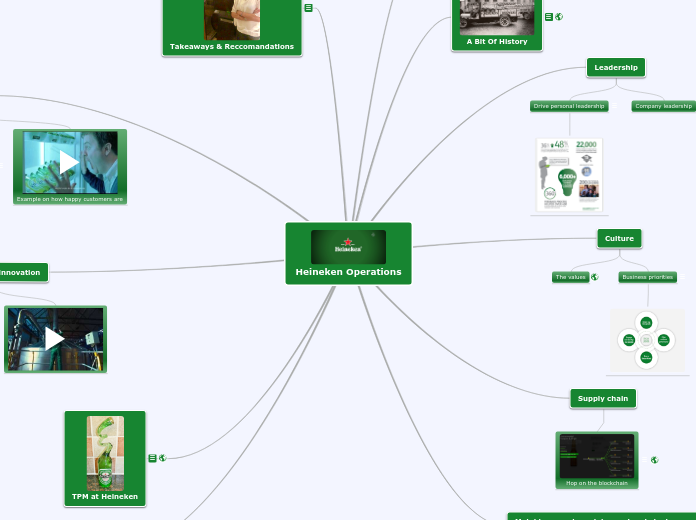

Welcome to my mind map about how technologies are reshaping the modern supply chain and logistics system!

My inspiration for this topic is from a recent workshop that IE AI Club hosted. The workshop features a guest speaker from IBM who teaches us about Watson Analytics, an AI empowered tool widely used in modern supply chains.

As the president of IE AI Club and a tech enthusiast, I am thrilled to give you a brief intro about the different types of technology applied in supply chain, including RFID, drones, Big Data, IoT, autonomous vessels, chipping, block chain and AI. I will also present to you some examples of companies using these technologies. I will link the mind map with the topics we learned in O&SCM course, and finish with some take-aways.

Let's get your journey started!

Takeaways

Congratulations, now you have learned about the different types of technologies that's applied in the supply chain, and a few companies that utilizes these technologies. Here are your takeaways from this mind map:

- Modern day technologies are reshaping how supply chain functions.

- Some examples include RFID, drones, Big Data, IoT, autonomous vessels, chipping, block chain and AI.

- Technologies contribute to creating efficient, lean services and Triple-A supply chain.

- Technologies can help reduce costs, wastes, lead times and bullwhip effect.

Don't worry if you cannot memorize all the technologies mentioned in the mind map, because technology is a process of constant revolutionizing. What's important is to keep in mind how important technology is in supply chain.

Hope you enjoyed the mind map! Feel free to share with me your thoughts or any other technology you know that's benefiting the supply chain. Cheers!

3 Companies You Should Know that are Utilizing Supply Chain Technologies

After we learn about how RFID, drones, Big Data, IoT, autonomous vessels, chipping, AI and block chain technologies are reshaping the supply chain, let's take a look at some industry leaders and their approaches for technology and supply chain.

What Amazon, Alibaba and IBM have in common is that these three industry giants all incorporates Triple-A Supply Chain. From drones to robots to sophisticated Watson Analytics tools, these companies pays greats attention to the agility, adaptability and alignment of their supply chain, which contributes greatly to their success.

We mentioned Amazon and Alibaba a lot in this course, as the two companies are the two stakeholders dominating the logistics and e-commerce industry. I used IBM, a non-typical supply chain company, to demonstrate that supply chain technologies are not only widely applied in the obvious logistics firms, but also in any types of businesses that aims to match demand and supply.

IBM

On Wednesday, March 7th, IE AI Club hosted aIBM Watson Analytics Workshop

with Luis Reina, one of IBM's leading Big Data architects at IBM Spain. Watson Analytics uses Natural Language Understanding and variety of Predictive Analytics to discover relationships, different facets and anomalies in Big Data. It is widely used in supply chain management.

Capitalizing on the machine-learning capabilities of IBM’s Watson, IBM has recently launched Watson Supply Chain aimed at creating supply chain visibility and gaining supply risk insights. The system uses cognitive technology to track and predict supply chain disruptions based on gathering and correlating external data from disparate sources such as social media, newsfeeds, weather forecasts and historical data.

Alibaba

Alibaba is Amazon's biggest competitor globally.

Let's take a look inside Alibaba's smart warehouse where robots do 70% of the work. These robots can carry up to 500 kilograms above them around the warehouse floor. They have special sensors to avoid colliding into each other and they can be summoned using wifi. When they run out of battery, they can take themselves to a charging station. A five minute charge can power them for 4/5 hours.

Amazon

When we think about supply chain management, Amazon is often the first company that comes to your mind.

Every time a customer places an order on Amazon.com, the company makes a promise to deliver it quickly. Supply Chain Optimization Technologies (SCOT) is the organization behind the company's ability to make that promise – to get customers what they need, when they need it and at a great price. Amazon uses advanced techniques and technologies including machine learning and data science to predict demand, forecast inventory needs and select suppliers.

Amazon Prime Air's drone usage and Amazon Go's cashier-less services are just two of the many SCOTs the company is utilizing.

6 Ways Modern Technology is Enhancing Operations and Supply Chain Management

New technologies are revolutionising multiple sectors, industries and processes and the supply chain is just one of the many that is seeing a constructive change.

Let's take a look at 6 ways new technologies can influence supply chain management in the foreseeable future.

Remember the video we watched in class of Amazon's drone deliveries? Prime Air is Amazon’s delivery system which uses drones to safely deliver packages to customers in less than 30 minutes. These rapid parcel delivery technologies will improve safety and overall efficiency. Well, this is just one of the many disruptive technologies that the supply chain will soon adapt.

All six examples of technologies mentioned here share a commonality, that is they all contribute to enhancing the speed, efficiency and accuracy of the supply chain. This is fundamentally related to the Lean Six Sigma and reducing wastes. Imagine decades ago, without these technologies, there had been much more problems with defects, overproduction, transportation, inventory, etc then compare to today.

Chipping

GPS tracking and chipping is revolutionising fleet management.

Telematics gives supply chain managers access to data, such as timings of routes and exactly how vehicles are driven, to allow them to make intelligent decisions about fleet training, fuel consumption, component failure rates and reasons for breakdown.

All these decisions can lead to savings of both time and money.

Autonomous Vessels

The future of worldwide shipping will not only include autonomous trucks on the road, but also autonomous vessels travelling across our oceans.

British luxury car company Rolls Royce have set a target to have remotely controlled autonomous vessels in international waters by 2025.

By 2035, ocean-going ships will have the ability to travel unmanned, with the ultimate goal of these intelligent vessels being a common sight on our oceans.

Internet of Things

By 2022, 1 trillion sensors will be connected to the internet according to research by the World Economic Forum.

The Internet of Things (IoT) will enable supply chain managers to achieve greater accuracy and visibility in all processes, as well as draw attention to possible faults throughout every supply chain operation.

The shipping element of the supply chain is already being enhanced by sensors as they can be used to track temperature, battery levels and potential errors that could affect goods and vehicles.

Drones

Over the next 15 years, drones will continue to evolve as a radical technology that industries are increasingly adopting. Drones are currently operating in the warehouses of two consumer-goods giants, Amazon and Walmart.

RFID

Radio Frequency Identification (RFID) enables the automatic tracking of inventory and assets and therefore simplifies the supply chain whilst reducing operating costs.

Using RFID tracking allows business owners to improve inventory management and increase the control they have over the location of their products.

Not only does RFID technology eliminate the need for hand-scanning, which reduces the time the process takes, it also helps reduce the amount of errors workers make.

Blockchain Technology

Believe or not, blockchain technology is capable of increasing supply chain transparency and traceability.

What is blockchain? A blockchain is a digitized, decentralized, public ledger of all cryptocurrency transactions. Constantly growing as ‘completed’ blocks are recorded and added to it in chronological order, it allows market participants to keep track of digital currency transactions without central recordkeeping. Each node (a computer connected to the network) gets a copy of the blockchain, which is downloaded automatically.

O&scm Topics

By creating transparency and traceability in supply chain, blockchain technology helps to reduce counterfeits and costs. This again is a great application of lean service.

In O&SCM course we talked about the bullwhip effect, a distribution channel phenomenon in which forecasts yield supply chain inefficiencies. It refers to increasing swings in inventory in response to shifts in customer demand as one moves further up the supply chain. Blockchain technology serves as an antidote to bullwhip effect.

Bullwhip Effect

As a result of the inefficiencies caused by supply chain bullwhip effects, companies lose money because they’re not able to accurately anticipate supply and demand.

There are three main issues that blockchain adoption can solve and reduce bullwhip effect:

1. A single, unified source of data, instead of multiple data silos

2. Flexible, collateralized assets, instead of capital underutilization

3. Instantaneous, real-time allocation of resources, instead of reactive

Blockchain is an excellent store of data — such as the state of a highly complex manufactured product — and can function as a secure ledger where each individual supplier or manufacturer registers state in real time.

Supply Chain Transparency & Traceability

Here's a video of what block chain is how it helps to ensure supply chain transparency and traceability. Specifically, blockchain supply chain innovations can deliver the following key benefits:

- Increase traceability of material supply chain to ensure corporate standards are met

- Lower losses from counterfeit/gray market trading

- Improve visibility and compliance over outsourced contract manufacturing

- Reduce paperwork and administrative costs

Artificial Intelligence in Supply Chain

Remember this picture? It was taken atIE AI Club's big Tech Talk event

last year, with Dean Kiron, TEDx Speaker Lolita and me (on the left). During the event we talked the role of AI in different industries. I will dedicate this section on how AI is changing the supply chain specifically.

But first, what's AI? Artificial Intelligence is an intelligence displayed by machines, in which, learning and action-based capabilities mimic autonomy rather than process-oriented intelligence.

The three most common applications of AI in supply chain are Chatbots, Machine Learning (ML) and Autonomous Vehicles. Let's explore them together.

O&SCM Topics

These AI technologies tie closely with the topics we covered in O&SCM class:

Chatbot focuses on lean service connecting both ends of the spectrum, the supplier and customers. It provides fast, real-time information and reduces delays, errors and information overload.

Machine Learning applied within supply chain management could help with forecasting within inventory, and matching demand and supply. ML could revolutionize the agility and optimization of supply chain decision-making: respond to short-term changes in demand and supply quickly and handle external disruptions smoothly.

For many logistics companies, the bottleneck is shipping time. Autonomous Vehicles reduces lead times and ensures faster and more accurate shipping.

Autonomous Vehicles

Intelligence in logistics and shipping has become a center-stage kind of focus within supply chain management in the recent years. Faster and more accurate shipping reduces lead times and transportation expenses, adds elements of environmental friendly operations, reduces labor costs, and — most important of all — widens the gap between competitors.

Machine Learning (ML)

What is Machine Learning?

Machine learning (ML) is a type of artificial intelligence that allows software applications to become more accurate in predicting outcomes without being explicitly programmed. The basic premise of machine learning is to build algorithms that can receive input data and use statistical analysis to predict an output value within an acceptable range.

Continue to learn how machine learning affects supply chain management and warehouse management.

Warehouse Management

Regardless of demand forecasting, supply flaws (overstocking or under stocking) can be a disaster for just about any consumer-based company/retailer.

ML provides an endless loop of forecasting, which bears a constantly self-improving output. This kind of capabilities could reshape warehouse management as we know today.

Supply Chain Planning (SCP)

By utilizing Machine Learning technology, supply chain planning professionals would be giving best possible scenarios based upon intelligent algorithms and machine-to-machine analysis of big data sets. This kind of capability could optimize the delivery of goods while balancing supply and demand, and wouldn’t require human analysis, but rather action setting for parameters of success.

Chatbots for Operational Procurement

Streamlining procurement related tasks through the automation and augmentation of Chabot capability requires access to robust and intelligent data sets.

Chatbots could be utilized to:

- Speak to suppliers during trivial conversations.

- Set and send actions to suppliers regarding governance and compliance materials.

- Place purchasing requests.

- Research and answer internal questions regarding procurement functionalities or a supplier/supplier set.

Introduction Video

First, let's take a look at a quick introductory video made by Accenture, about how important technology is for supply chain.

Indeed, from suppliers to distribution channels, technology plays an integral role of connecting every part of the value chain.