realizată de Jaskaran Singh 4 ani în urmă

687

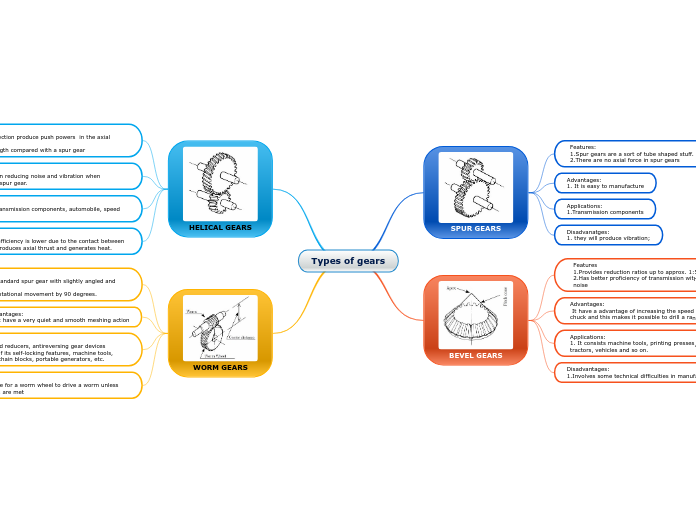

Types of gears

Worm gears have slightly angled and curved teeth, changing rotational movement by 90 degrees. They are used in speed reducers, machine tools, and portable generators, benefiting from quiet, smooth meshing but cannot drive a worm wheel unless specific conditions are met.