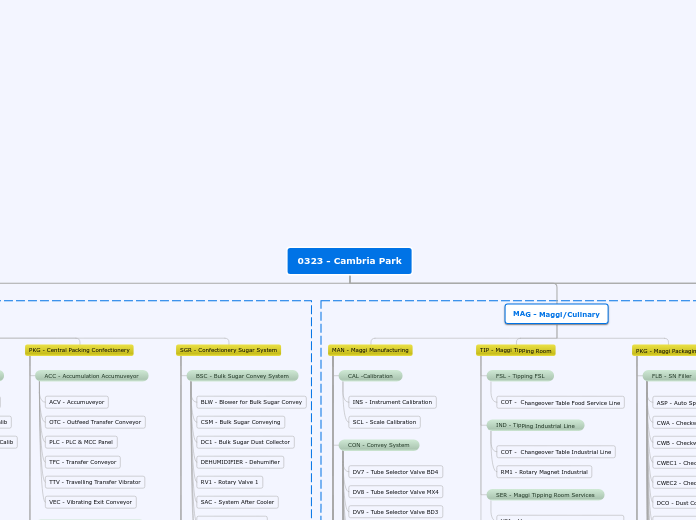

0323 - Cambria Park

BLG - Buildings

YRD - Yards

WHS - Warehouses

WBH - Workshop & Boiler House

TSD - Applications

QAD - Quality Assurance Department

MTO-CAN - Minties Canopy Building

MT1 - Minties 1st Floor Building

MT0 - Minties Ground Building

MAG - Maggi Building

KL0 - Kools 1st Floor Building

Chocolate

KL3 - Kools 3rd Floor Building

KL2 - Kools 2nd Floor Building

CMR - Chocolate Melting Room

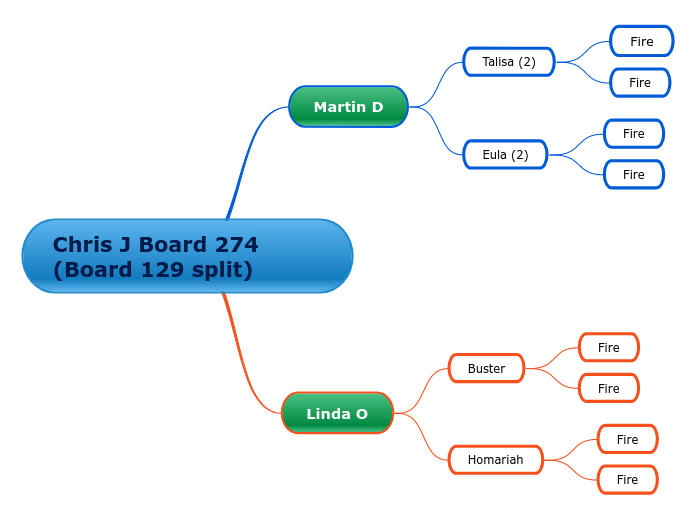

FIR - Fire Protection

SYS - Fire Protection Systems

WBH - Workshop & Boiler House Fire Prot Sys

MIN - Minties Building Fire Protection Systems

MAG - Maggi Fire Protection Systems

KOL - Kools Building Fire Protection Systems

ADM - Admin Building Fire Protection Systems

CON - Building Confectionery

KL1 Kools 1st Floor Building

EBS - Sugar Day Bin Room Earth Bonding System

AHU - AHU 16 Chocolate Packing

OFF - Buildings Conf Office

MIN - Buildings Conf Minties

PAT - Minties Area Portable Appliances

LBO - Buildings Conf Low Boil

PAT - Low Boil Area Portable Appliances

LAB - Buildings Laboratory

PAT - Laboratory Portable Appliances

HBO - Buildings Ground Building

KL0 - Kools Ground Building

DRAINS - Drains

RD4 - Rapid Roll Door A007-out

RD3 - Rapid Roll Door A007-Air

RD2 - Rapid Roll Door A008-A007

RD1- Rapid Roll Door A003-A007

LIT - Building Lighting

LFT - Otis Lift

LAN - LAN Cabling Kools Building

ELT - Emergency Lights Kools

AHU - AHU 13 Kools

AH2 - AHU 12 Kools C&M Pan Room

AH1 - AHU 11 Kools Packing

CPA - Buildings Conf Central Pack

COM - Buildings Conf Compressed

AMT - Amenties Building

ADM - Administration Building

SER - Service

WWT - Waste Water Treatment

WTR - Town Water Supply

STM - Steam

SBM - Main Switchboard Maggi

SBC - Main Switchboard Confect

SB1 - Switchboard Main

PSR - Pressure Vessels

PAG - PAG Services

MWS - Main Workshop

MCS - Maggi Common Services

MAG - Services in Maggi Building (Elect)

HW3 - Hot Water Systems 45 deg

HW2 - Hot Water Washdown

HW1 - Hot Water Systems 80 deg

GAS - Natural Gas Supply

CWS - Chilled Water Services

CWC - Chilled Water Confec

CON - Services in Confectionery Building (Elect)

CKL - Services in Kools Building (Elect)

CHM - Chilled Water Maggi

AIR - Compressed Air

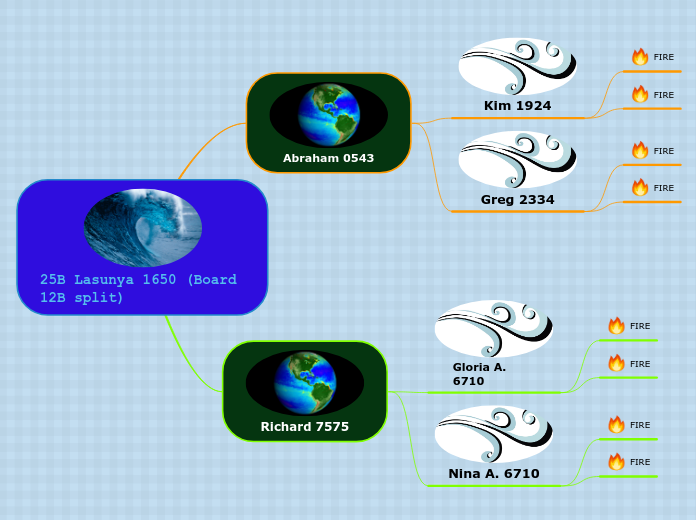

MAG - Maggi/Culinary

PKG - Maggi Packaging

SVL - Volpack

SMD - Sachet Metal Detector

SCL - Yamato Scale

P02 - UBI Printer

MCN - Mobile Conveyor

INS - Insertion Machine For Oven Bags

EQU- Equaliser

ELC - Elevator Conveyor For Oven Bags

PACKING STATION

FILLER

CN3 - Conveyor Exit Applicator

CN2 - Conveyor before Applicator

CN1 - Conveyor 90Def

APB - UBI Applicator

SHF - Holler F

VJP2 - Videojet Printer

VJP1 - Videojet Printer

LFT - Foil Lifter Holler F

CWR - Checkweigher - Ishida

CW2 - Checkweigher - Ishida

CN5 - Packing Conveyor

CN4 - Conveyor to Packing (Horseshoe)

CN3 - Videojet Conveyor

CN2 - Conveyor into Bosch

CN1 - Conveyor After Checkweigher 2

BCM - Bosch Cartoning Machine

SHD - Holler D

VEG DOSER - Veggie Doser

PAC - Auto Sachet Packer RML

LFT - Foil Lifter Holler D

IP1 - Printer

FILLER - Holler

EQ1- RML Equaliser

CON - Sachet Incline Conveyor into RML

CN4 - Separation Conveyor into Sellotaper

CN3 - 90Deg Bend Conveyor into Sellotaper

CN2 - Conveyor After Auto Sachet

CN1 - Conveyor Before Auto Sachet

CEB - RSC Case Erector

SH2 - Holler E

VJP - Videojet Printer

VEG - Veggie Doser

SLO - Feed Silo

RST - Sachet Hooler 2 Line - Roast

ROL - Roller Conveyor

P04 - UBI Printer

FIL - Holler

EQU - Kinetic Equaliser

DVT - Divert Conveyor Soup to Roast

CWR - Checkweigher

CON - Packing Conveyor

CN1 - S Conveyor to Soup Packing

BTC - Box Turn Conveyor

APP - UBI Applicator

FSL - Matteer/ Food Service Line

CWP - Cube Press 2

SELLOTAPE MACHINE

SCALE - Scale

MDT - Metal Detector

CW1 - IMA Wrapper

CP2 - Cube Press 2 - Bonals

CON5 - Cube Transfer Conveyor

CON4 - IMA Side Irons Conveyors

CON3 - IMA Infeed Conveyor 3

CON2 - IMA Infeed Conveyor 2

STRETCH WRAPPER

PCB - UB1 Printer

CBK-HOPPER

C0N1 -Metal Detector Conveyor 1

BIC - Bucket Incline Conveyor

FLB - SN Filler

SIL - Feed Silo

SIC - Conveyor into Sellotaper

SEL - Sellotape Machine

RCE - RML Box Erector

PRINTER - Videojet Printer

OSC - Ostma Sachet Collator

OEC - Exit Conveyor - Ostma

NWS - Net Weigh Scale

MTD - Metal Detector

LABELLER - Labeller

ISC - Incline Conveyor to Sellotaper

FOC - Twin Outfeed Conveyor

FILLER SN - SN Filler

EEC2 - Equaliser Lane 2

EEC1 - Equaliser Lane 1

DCO - Dust Collector

CWEC2 - Checkweigher Lane 2 Exit

CWEC1 - Checkweigher Lane 1 Exit

CWB - Checkweigher Lane 2

CWA - Checkweigher Lane 1

ASP - Auto Splicer - Butler

TIP - Maggi Tipping Room

SIV - Sifters

SL2 - Vibco Large 2 Industrial Line

SL1 - Vibco Large 1 FSL

S09 - Cube Press 2

S08 - Cube Press 1

S07 -Sifter Ilapack

S06 -Sifter Sprinkle

S05 -Sifter Holler F

S04 -Sifter Holler D

S03 -Sifter Holler E

S02 -Sifter BMR

S01 -Sifter Volpak

SER - Maggi Tipping Room Services

V01 - Vacuum Cleaner Nifisk Tipping Room

IND - Tipping Industrial Line

RM1 - Rotary Magnet Industrial

COT - Changeover Table Industrial Line

FSL - Tipping FSL

COT - Changeover Table Food Service Line

MAN - Maggi Manufacturing

Permanent Silo

SER - Manufacture Services

V07 - Vacuum Cleaner Tiger

V06 - Vacuum Cleaner VHW 421 Gluten

V05 - Vacuum Cleaner VHW 421 Gluten

V04 - Vacuum Cleaner VHW 421 Atex

V03 - Vacuum Cleaner CFM

V02 - Vacuum Cleaner T22

V01 - Vacuum Cleaner GD5

DC2 - Dust Collector 2 (MX4)

DC1 - Dust Collector 1 (MX1,2,3)

SBP - Semi-bulk Pit Area

WH1 - Weigh Hopper 1 (Premix)

TH3 - Transfer Hopper 1 (MX3)

TH2 - Transfer Hopper 1 (MX4)

TH1 - Transfer Hopper 1 (MX1,2)

RHP - Rotating Hopper (Pit)

DCR - Dust Collector - Rotating Hopper

SBM - Semi-bulk Mezzanine

WH7 - Weigh Hopper 7

WH6 - Weigh Hopper 6

WH5 - Weigh Hopper 5

WH4 - Weigh Hopper 4 (Salt)

WH3 - Weigh Hopper 3 (Sugar)

WH2 - Weigh Hopper 2 (MSG)

PM8 - Premix station 8

PM7 - Premix station 7

SBG - Semi-bulk Ground Area

BBU5 - Bulk Bag Unloader 5 (Flour)

BBU4 - Bulk Bag Unloader 4 (Non Flour)

BBU3 - Bulk Bag Unloader 3

BBU2 - Bulk Bag Unloader 2

BBU1 - Bulk Bag Unloader 1

MLL - Mixer Mills

SV2 - Sieve No2 Fryer

ML2 - Mill No2 Daverio

CS2 - Conveyor Screw Mill No2

GFM - Gluten Free Mixer Area

SPC - Spice Room Equipment

MIC - Caramel Microwave Oven

HP4 - Hydraulic Power Pack 4

HP3 - Hydraulic Power Pack 3

HP2 - Hydraulic Power Pack 2

HP1 - Hydraulic Power Pack 1

RH1B - Receiving Hopper 1B

RH1A - Receiving Hopper 1A

NF2B - Non Flour Receiving Hopper 2B

MX2 - Mixer No 2

MX1 - Mixer No 1

FH2 - Flour Receiving Hopper 2

GMA - Gluten Mixer Area

FH4B - Receiving Hopper 4B

NF3A - Non Flour Receiving Hopper 3A

MX4 - Mixer 4

MX3 - Mixer 3

FH4A - Flour Receiving Hopper 4A

FH3B - Flour Receiving Hopper 3B

GFA - Gluten Free Bag Dump Area

DCF - Dust Collector Fan

BD2 - Bag Dump No 2

BD1 - Bag Dump No 1

GBA - Gluten Bag Dump Area

WH12 - Weigh Hopper 12

DCF - Dust Collector Bin

BD4 - Bag Dump No 4

BBU - Bulk Bag Unloader 4

FLO - Flour Silo Room

WH8 - Weigh Hopper 08

SL4 - Silo 4

SL3 - Silo 3

SL2 - Silo 2

SL1 - Silo 1

CON - Convey Line to Silos

FAT - Fat Area

TANK - Tank Fats

EXT-CHT - Chain Hoist

CON - Convey System

MUN - Munters dehumifier MX2700

LNP - Convey Line From Pre-Mix

DV6 - Tube Selector Valve PMDV1

DV5 - Tube Selector Valve SPDV2

DV4 - Tube Selector Valve SPDV1

DV2 - Tube Selector Valve SBDV2

DV1 - Tube Selector Valve SBDV1

VP6- Vacuum Pump MS156

VP5- Vacuum Pump MS155

VP4- Vacuum Pump 41B

VP3- Vacuum Pump 41A

VP2 - Vacuum Pump 40B

VP1 - Vacuum Pump 40A

LN4 - Convey Line 4

LN3 - Convey Line 3

LN2 - Convey Line 2

LN1 - Convey Line 1

DV9 - Tube Selector Valve BD3

DV8 - Tube Selector Valve MX4

DV7 - Tube Selector Valve BD4

CAL -Calibration

SCL - Scale Calibration

INS - Instrument Calibration

CON - Confectionery

SGR - Confectionery Sugar System

PDA - C & M Pans Day Bin Area

SST - Sugar Silo

SIL - Sugar Silo 70 T

SLM - Sugar Mill Bauermeister

SA2 - Sugar Feed Auger 1

SA1 - Sugar Feed Auger 1 45deg

RVO - Rotory Valve Mill Outlet

RVI - Rotory Valve Mill Inlet

MCC - Sugar Mill Control System

LDA - Low Boil Day Bin Area

KDA - Kools Day Bin Area

SDB - Sugar Day Bin

BSC - Bulk Sugar Convey System

SIFTER - Sifter

SDB - 1 Tonne Sugar De-bagging

SC1 - Screw Conveyor

SAC - System After Cooler

RV1 - Rotary Valve 1

DEHUMIDIFIER - Dehumifier

DC1 - Bulk Sugar Dust Collector

CSM - Bulk Sugar Conveying

BLW - Blower for Bulk Sugar Convey

PKG - Central Packing Confectionery

SER - Central Packing Services

PS2 - Pallet Stacker

PS1 - Reach Truck

PLR - Palletising Robot

SWP - Stretch Wrapper JMP

ROB - Kawasaki Robot

P2C - Local Dispenser 2 - Export

P1C - Local Dispenser 1 - Local

CI1 - Infeed from Kawa 2

C03 - 3rd Outfeed Kawa 2

C02 - 2nd Outfeed Kawa 2

C01 - 1st Outfeed Kawa 2

K2L - K2 Whole Line

YW2 - Yamato Weigh Head Side 2

YW1 - Yamato Weigh Head Side 1

VIB - Shaker

VAC - Vacuum Cleaner

TUR - Empty Carton Turner

TFC - Transfer Conveyor to Weigh Head

TC4 - Conveyor Transfer 4

TC3 - Conveyor Transfer 3

TC2 - Conveyor Transfer 2

TC1 - Kawashima feed conveyor to Ishida

SL2 - Sellotape Machine 3M

SL1 - Sellotape Machine Siat

RTT - Turntable

ROL - Portable Conveyor

RJC - MD Reject Conveyor

PKT - Packing Table

NWT - Net Weight Table

NWS - Net Weight Scale

MSC - Merging Conveyor

MH6 - Hopper 6

MH5 - Hopper 5

MH4 - Hopper 4

MH3 - Hopper 3

MH2 - Hopper 2

MH1 - Hopper 1

MD1 - Metal Detector

MCI - Iso Flow

LT1 - Tube Lifter

LFT - Foil Lifter

HF2 - Date Coder Side 2

HF1 - Date Coder Side 1

CW2 - Case CheckWeigher

CW1 - Bag CheckWeigher

CR4 - Conveyor 12 Deline to Robot

CR3 - Conveyor 11 Overheal Roller

CR2 - Conveyor 10 Incline to Robot

CR1 - Conveyor 9 After Sellotape

COD - Marsh Printer

CN8 - Conveyor Marsh Printer

CN7 - Conveyor Case Checkweigher

CN6 - Conveyor 6 2nd Sweep

CN5 - Conveyor 5 1st Sweep

CN4 - Transport Conveyor

CN3 - Conveyor 3 Short Blueprint

CN2 - Conveyor 2 Long Blueprint

CN1 - Conveyor 1 Bag Checkweigher

CFC - Coffin

CF2 - Gentle Belt

CEB - RSC Case Erector

BPP - Blueprint

BEV - K2 Bucket Elevator

BE2 - Conveyor Elevator K1

CAL - Central Packing Calibration

INS - Central Packing Instrument Calib

ACC - Accumulation Accumuveyor

VEC - Vibrating Exit Conveyor

TTV - Travelling Transfer Vibrator

TFC - Transfer Conveyor

PLC - PLC & MCC Panel

OTC - Outfeed Transfer Conveyor

ACV - Accumuveyor

SER - Service Equipment

CAL - Confectionery Serivices Calibration

SCL - Conf Services Scale Weigh Calib

MDT - Conf Services Metal Detect Weigh Calib

INS - Conf Services Instrument Weigh Calib

CWR - Conf Services Check Weigh Calib

KOL - Whole Line Confectionery Kools

SER - Kools Services

W65 - Jacket Water 65deg

V01 - Vacuum Cleaner

HTW - Hot Water Set 99deg

AHU 28 - AHU 28 Sealing Pans

PAN-2 SEALING - Pan 2 Sealing

SPRAYBAR - Spray bar Assembly 2

PN2 - Pan 1 Sealing

LBH - Live Bottom Pan 2

PAN-1 SEALING - Pan 1 Sealing

SPRAYBAR - Spray bar Assembly 1

PN1 - Pan 1 Sealing

LBH - Live Bottom Pan 1

LBC - Live Bottom Conveyor

MM4 - Mass Minties - Kools

TCW - Theegarten WHD2 Cut and Wrap

SRS - Single Rope sizer

RT1 - Relax Tunnel Line 2

RS1 - Sope Sizer Line 2

RC1 - Rope Speed Control Table Line 1

OC4 - Overhead Conveyor 4

OC3 - Overhead Conveyor 3

OC2 - Overhead Conveyor 2

CR2 - Conveyor Relax 2

CR1 - Conveyor Relax 1

CGT - Conveyor Grading Table

CE2 - Conveyor Elevating 2 - Line 2

C01 - Conveyor Outfeed 42C

BF2 - Batch Former Line 2

42C - AMP Rose 42C

MK4 - Mass Kools

UP3 - Uniplast line 3

RS3 - Rope Sizer Line 3

RS2 - Rope Sizer Line 1

CE3 - Conveyor Elevating Line 3

BF3 - Batch Former 3

BF1 - Batch Former Line 1

MFC - Mass Forming Common

ECT - Cooling Tunnel

CTC - Conveyor Transfer 1

CT1 - Conveyor Exit Transfer 1

CSC - Conveyor Swing Cooling Tunnel

CEC - Cooling Tunnel Incline Exit Conveyor

MC4 - Mass Transfer System

STR - Sheeting Rollers

CT1 - Transfer Conveyor

CDD - Conveyor Dropdown

MC3 - Mass Cooling

RUF - Ruffinatti Cooling Drum

CWS - Cooling Water System

CON - Layering Conveyor

MC2 - Kools Cookers Whip Fat

HWS - 99deg Hot Water System

WS1 - Net Weight Scale 1

VP2 - Vacuum Pump 2

VP1 - Vacuum Pump 1

TNK - Tank Fat Fondant

TK2 - Whip Holding Tank

TK1 - Tank Whip Mixing

PW2 - Presswhip 2

PW1 - Presswhip 1

PV1 - Cooker Panel View

PP2 - Fat Fondant Pump

PP1 - Fat Transfer Pump

PMP - Whip Pump

MLT 2 - Pallecon Metler

MLT 1 - Pallecon Metler

MIX - Portable Mixer

CK2 - Cooker 2

CK1 - Cooker 1

MC1 - Mass Cooking Syrup

TK1 - Mixing Tank Base Syrup

PIP - Syrup Pipe Work

EXT - Extraction Fan

BDS - Bag Dump Station

AF2 - Accurate Feeder Sugar Day Bin

AF1 - Accurate Feeder Bag Dump

KP4 - Bosch Flow wrap line

OFC - Out Feed Conveyor

NVH - Nupac Vibrating Hopper

MDT - Bosch Flow Wrap Metal Detector

IGC - Infeed Goose Neck Conveyor

BFW - Bosch Flow Wrapper

KM8 - Kools Panning

PN6 - Pan No.6 System

PN5 - Pan No.5 System

PN4 - Pan No.4 System

PN3 - Pan No.3 System

PN2 - Pan No.2 System

PN1 - Pan No.1 System

MAN - Kools Panning Manual

HOP - Kools C&M Syrup Panels

ECP - Electrical Control Panels

DFM - Dust Filter For Manual P

CN2 - C&M Loading & Unloading E

CN1 - C&M Loading & Unloading E

BSS - C&M Syrup System

KM7 - Batch Maturing Oven

SPR - Spreader Belt

CN2 - Conveyor Bank 2 Maturing

AH3 - AHU 34 Kools Maturing

AH2 - AHU 33 Kools Maturing

AH1 - AHU 32 Kools Maturing

KM6 - Batch Hopper Caster Sugar

VPP - Vacuum Pump M45

RTV - Rotary Valve M41

CH1 - Chain Hoist

BBF - Bulk Bag Frame

AUG - Auger Caster Sugar Supply

AGF - Auger FLEX

AF3 - Auger Feeder 3

AF2 - Auger Feeder 2

AF1 - Auger Feeder 1

KM5 - Kools Manufacture Sealing

TK1 - Sealing Syrup Cooker

SHT - Syrup Holding Tank

PNE - Festor Fied Bus Solenoid

MCC - Motor Control Centre

DC1 - Dust Collector

CO8 - Conveyor C8 Pan Discharge

CN4 - Conveyor Maturing Outfeed Elevating

CN3 - Conveyor Elevating

CN2 - Conveyor Maturing Exit

CN1 - Conveyors Cooling M24

C91 - Conveyor Elevating To Pans

C7B - Feed Conveyor to pans

AHU - AHU 27 Sealing storage

KM1 - Kools Grading & Mixing

VHP - Vibratory Hopper

TBL - Table Elevator Conveyor

RACKING - WIP Racking

MXS - Mixing Station

MHS - Mixing Station Hydraulic System

ECN - Elevating Conveyor

CNE - Conveyor Elevating For Mixing Station

CN1 - Discharge Conveyor

CGR - Grader Conveyor

CAL - Kools Calibration

INS - Kools Instrument Calibrations

LBL - Low Boil

WRP - Wrapping Lines

WU1 - U1 Wrapper

TW2 - 42B Stick Wrapper 2 (42CB)

TW1 - S42 Twist Wrapper 1 (42CA)

SW2 - R75 Stick Wrapper 2 (R75A)

SW1 - R75 Stick Wrapper 1 (R75B)

SRC - Sizing Roller Line C

SRB - Sizing Roller Line B

SRA - Sizing Roller Line A

OEC - Out Feed Elevator C

OEB - Out Feed Elevator B

OEA - Out Feed Elevator A

GRC - Post Graining Cooling Conveyor

GOC - Graining Oven Outfeed Conveyor

GNT - Graining Tunnel

FCG - Feed Conveyor Graining Oven

CF2 - Centre Filler 2

CF1 - Centre Filler 1

BRC - Batch Roller Line C

BRB - Batch Roller Line B

BRA - Batch Roller Line A

SER - Services to Low Boil

CWT - Cooling Water Low Boil

CAL - Low Boil Calibration

INS - Instrument Calibrations

MAN - Manufacturing

VP1 - Vacuum Pump Busch

TNK - Base Syrup Tank

TCC - Transfer Conveyor C

TCB - Transfer Conveyor B -Dropdown

TCA - Transfer Conveyor A

TAC - Transfer Incline Conveyor

SVA - Silverson Tank A

SRS - Sheeting Rollers

SCM - Base Syrup SCM Pump

PUL - Puller

PMX - Paste Mixer

MCD - Mass Cooling Drum

FMT - Base Syrup Fat Melter

DPB - Discharge Pump B

DPA - Discharge Pump A

CKB VACUUM SYSTEM

CKB - Cooker B

CKA VACUUM SYSTEM

CKA - Cooker A

BTB - Batching Tank B

BTA - Batching Tank A

BSP - Base Syrup