av Alexandre Condrau för 6 årar sedan

226

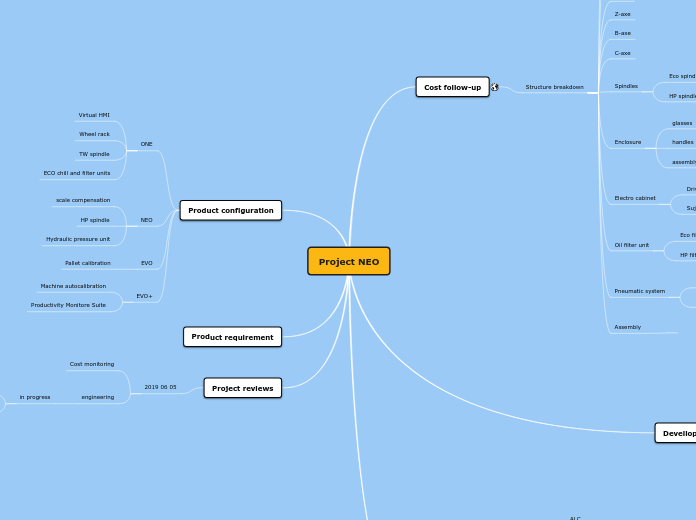

Project NEO

The document outlines the various stages and components involved in Project NEO, focusing on development planning, evaluation, sourcing, assembly, and detailed engineering. It mentions different product requirements and configurations, including the EVO+ productivity monitoring suite, machine autocallibration, and various hardware components like spindles, hydraulic pressure units, and calibration systems.