Lean Manufacturing and Operational Innovation: Luxury Brands

Hi Prof Felipe and my fellow classmates!

Today I'll be presenting to you a few aspects of Operational Innovation/Management and some of Lean Manufacturing within the Luxury Industry. This is an Industry we didn't quite brush up upon during the duration of our course but one that I have always been interested in and thought it would be challenging yet rewarding to work on something unique. Hope you all enjoy the presentation, please do leave your comments.

Many thanks,

Jawayria Yawar

Burberry and disruption

On the other side, we have Burberry, an independently owned Luxury Fashion House that is fast becoming the leader in retail tech. They have a very different way of working online from LVMH and have recently revamped themselves from losing clients and sales to being on the top again. They began by targeting young consumers like Milennials, staying true to their British roots and banking on their signature Trench coats and introducing smart personalization allowing customers to not only personalize their products but also unlock videos and craftsmanship about how their product was created. This amongst several key changes brought Burberry back to being one of the leaders.

How Burberry revamped and revitalized itself

How Burberry became a leader in retail tech

Hermes and Innovation

Hermès is perceived as one the most exclusive luxury brands in the World.The business is integrated, centered on a unique brand strategy, rooted in its longstanding history of producing ultra-high quality distinguishable products requiring high levels of craftsmanship, mixing an essence of understated elegance, creativity, and inimitable service. The group production is organized by “Metiers” – the artisanal divisions (Leather, Ready-To-Wear (RTW), Silk, Fragrances, Watches, Petith)

Ranked #13 on Forbes’ list of the world’s most innovative companies (ahead of Netflix) Hermès changes every six months a third of its 50,000 SKUs thanks to freelancer’s creativity (60% of the Group’s designers). The innovative character of the group is exemplified by its new division, Petith featuring one of a kind objects made from rejects that would be thrown away usually.

Innovation through rejected materials

One of the most Innovative Digital Brands!

Hermes banking on it's creativity

Conclusion

We have seen how being digital makes a huge difference for Luxury brands as not all of them have been so keen on adopting it a 100% so far. By taking the example of Burberry and Hermes I feel Louis Vuitton could take a step ahead digitally and interact with their customers increasingly online and have a greater online presence to reinforce themselves as a leader in the luxury world in the day and age of social media.

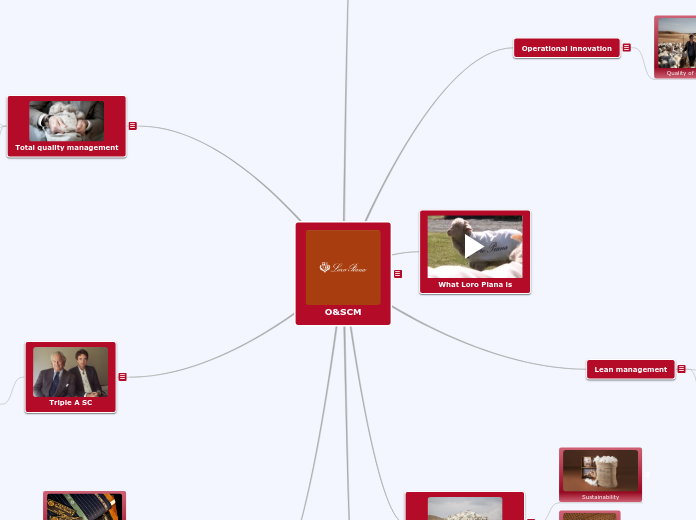

LVMH

LVMH Moët Hennessy Louis Vuitton SE, better known as LVMH, is a European multinational luxury goods conglomerate. LVMH has acquired several other luxury brands over the years and remains at the pinnacle of luxury. We are going to discuss a few operationnal innovations at Louis Vuitton which is a big part of the LVMH Family.

Sustainability at LVMH

Louis Vuitton

Louis Vuitton

Louis Vuitton or shortened to LV, is a fashion house and luxury retail company founded in 1854 by Louis Vuitton. The label's LV monogram appears on most of its products, ranging from luxury luggage trunks and leather goods to ready-to-wear, shoes, watches, jewelry, accessories, sunglasses and books. Louis Vuitton is one of the world's leading international fashion houses; it sells its products through standalone boutiques, lease departments in high-end department stores, and through the e-commerce section of its website. For six consecutive years (2006–2012), Louis Vuitton was named the world's most valuable luxury brand. Its 2012 valuation was US$25.9 billion. The 2013 valuation of the brand was US$28.4 billion with revenue of US$9.4 billion. The company operates in 50 countries with more than 460 stores worldwide.

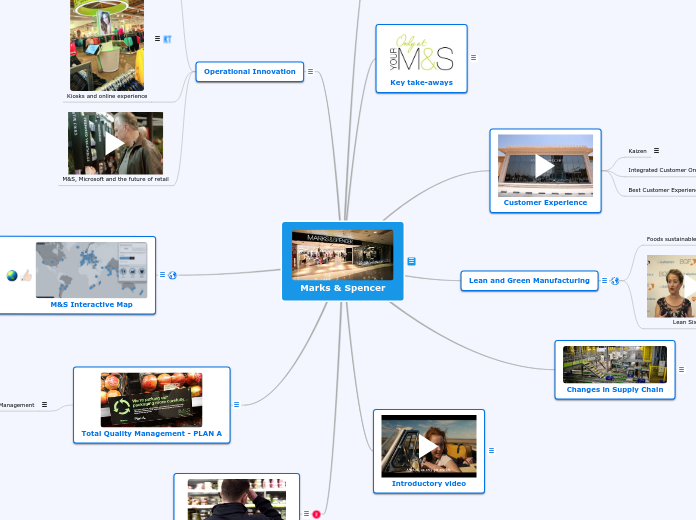

Technology in Operations

Part of the Overhaul also included technological changes within the Company like adopting the e-learning platform EKP:

- This provided with training for soft skills, system usage and anti counterfeit training

- Cost-effective, offering educational diversity and flexibility

- Easily accessible and user friendly

Product Lifecycle management was alsoincorporated

Lean Operations & robots at LV

Lean Operations

Please watch the video from 4:25.

Inspired by Japanese carmakers especially Toyota, a new lean process was implemented in factories. By reorganizing teams of about 10 workers in U-shaped clusters, Vuitton was able to free up 10% more floor space in its factories and hired 300 more people instead of renting another factory space.

At their shoe factory in Italy, robots now fetch the foot molds around which a shoe is made instead of workers walking back and forth from their workstation to the shelves. The use of robots has saved considerable time and also reduced the number of people who would have been needed to perform the task

LV's supply chain overhaul

A few years ago Louis Vuitton is pursued a more-fundamental overhaul. With help from management consultants at McKinsey & Co., Vuitton set out to make its manufacturing process more flexible, . "Behind the creative magic of Louis Vuitton is an extremely efficient supply chain," boasted Yves Carcelle, the brand's chief executive officer

A few years ago it would take 20-30 craftsmen about 8 days to put together an LV Bag. With the help of the new process LV managed to reduce it to clusters of 6-12 people performing different tasks and can now assemble an artisan LV bag within just a day!

LVMH Group History

How to incorporate Lean in Luxury

Lean thinking is one strategy being used to reduce waste while maintaining quality. Luxury fashion has been affected by the global financial crisis and needs to adjust to new business strategies to reduce excess costs. To implement lean thinking there are many different barriers like cultural differences, communication, and commitment from employees, management and suppliers. However, implementing lean thinking in the luxury fashion market has unique barriers, like high variability, quality and a short product life cycle.

Lean thinking and luxury are opposing principles; lean thinking streamlines manufacturing, preserving value with while reducing work, and luxury responds to customers and their desires, making each good personalized to the customer. Which is why implementing lean thinking into luxuxy fashion is difficult to implement.

Luxury market has remained steady through depressions and recessions, however recent trends in the global economy have seen a decline in luxury purchases. Luxury goods are unique and quality products, usually with a premium price. Adopting lean thinking and strategy can eliminate waste and cut costs within fashion houses, and overall improve their operations

Supply Chain Vertical Integration

Supply Chain Vertical Integration

The importance between the supply chain and manufacturers is demonstrated with the success of high street giant Zara's transformation into lean logistics. A recommendation for luxury designers is to vertically integrate the supply chain. A barrier that is commonly seen with lean thinking is building relationships with suppliers. Suppliers are integral to lean practices as they effect quality and any disruptions will affect production and increase waste. Luxury Fashion houses should begin to integrate the supply chain by improving supplier relationships and incorporating the finishing embellishments inhouse. Providing services inhouse allows the fashion house to react to different season trends quicker, changing embellishments and designs as needed. This ensures quality is maintained throughout the process and that waste is eliminated, in extra costs and time.

Takt Time

The minimal recommendation a luxury company can adopt to integrate lean thinking is focusing on takt time. Take time is the average measure of the time to produce a product depending on customer demand, therefore lowering inventory. This could be taken into account for producing iconic items that brands have such as the Hermes Birkin bag which not only starts at USD 6000 but it represents luxury. It has a large demands, and represents a large profit margin for Hermes. To integrate lean thinking, apply takt time to produce luxury products at a standard time, per customer demand. Quality and demand of the iconic product is still maintained, while the amount of wasted products, time and inventory is lowered.

you'll come up with original ideas

Kanban

Kanban

To continue improving communication and optimizing a 'pull' system through production, a Kanban system should be introduced into luxury supply chains. Kanban is a scheduling system for lean manufacturing and a method of just in time manufacturing; it is an inventory system to control the supply chain. Kanban uses demand signal to slow down the supply chain to re-supply according to the demand of the customer and as inventory is needed, this system keeps lead times and inventory low. Kanban is a system to initiate and improve on communication in the supply chain and reduces inventory and time waste.

VSM

Value Steam Mapping

To fully comprehend and discover where in the supply chain processes need and can be improved a value stream map should be made. Value stream mapping is a simple tool used to redesign value streams. Value stream mapping analyzes the current value stream and discovers sources of waste and uncovered and reduces. Communication between workers and management is a problem with introducing lean thinking, mapping the value stream can clearly indicate and communicate problems in the supply chain to the entire company. A recommendation in implementing lean thinking in luxury fashion, is to map the value stream as it increases communication between employees and clearly identifies problems and facilitates formulating goals to improve the supply chain.

Luxury Goods Market

Luxury Industry

The overall luxury industry comprises nine segments, led by luxury cars, luxury hospitality and personal luxury goods, which together account for more than 80% of the total market.

Considering all segments, the luxury market grew by 5% to an estimated €1.2 trillion globally in 2017. Sales of luxury cars continued to dominate the market, increasing by 6% to reach €489 billion in total. Luxury experiences remained very attractive to consumers, as illustrated by sales growth of high-end food and wine (both up 6% from last year), and sales of luxury cruises (up an impressive 14%).

The market for personal luxury goods—the "core of the core" and our focus—reached a record high of €262 billion, boosted by a revival of purchasing by Chinese customers both at home and abroad, as well as strong trends within other customer groups and in other regions. That represented 5% growth at current exchange rates, and 6% at constant exchange rates.

Refer to pages 6,8,9 and 15 in the next link please.

Luxury shopping in the digital age.

Millenials Reshaping the Luxury Goods Market

Luxury Brands Need to go Digital or face extinction?