Prayukta Padelkar

BBT-02-17035

BBT-703 Assignment week 11

Formulation broadly refers to the maintenance of activity and stability of a biotechnological products during storage and distribution. The formulation of low molecular weight products (solvents, organic acids) can be achieved by concentrating them with removal of most of the water. For certain small molecules, (antibiotics, citric acid), formulation can be done by crystallization by adding salts.

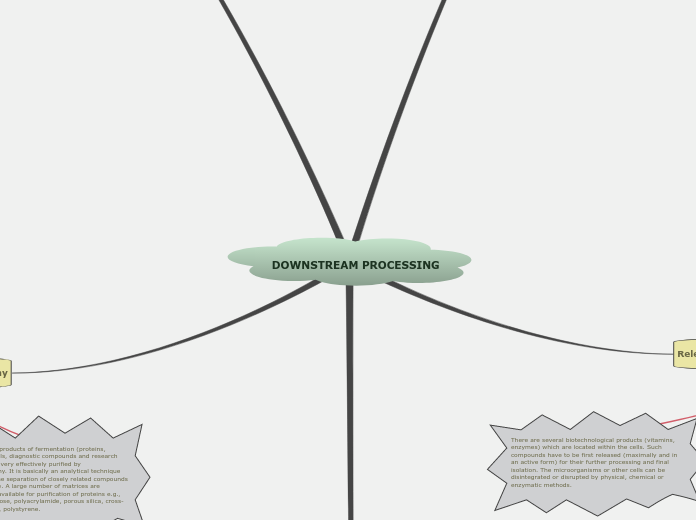

The biological products of fermentation (proteins, pharmaceuticals, diagnostic compounds and research materials) are very effectively purified by chromatography. It is basically an analytical technique dealing with the separation of closely related compounds from a mixture. A large number of matrices are commercially available for purification of proteins e.g., agarose, cellulose, polyacrylamide, porous silica, cross- linked dextran, polystyrene.

The filtrate that is free from suspended particles (cells, cell debris etc.) usually contains 80-98% of water. The desired product is a very minor constituent. The water has to be removed to achieve the product concentration. The commonly used techniques for concentrating biological products are evaporation, liquid-liquid extraction, membrane filtration, precipitation and adsorption.

There are several biotechnological products (vitamins, enzymes) which are located within the cells. Such compounds have to be first released (maximally and in an active form) for their further processing and final isolation. The microorganisms or other cells can be disintegrated or disrupted by physical, chemical or enzymatic methods.

The first step in product recovery is the separation of whole cells (cell biomass) and other insoluble ingredients from the culture broth Several methods are in use for solid-liquid separation. These include flotation, flocculation, filtration and centrifugation.

DOWNSTREAM PROCESSING

Type in the name of the novel and movie you are going to compare and contrast.

Example: Great Expectations.

Purification by Chromatography

Use point-by-point organization in the body section to present the characteristics briefly stated in the thesis.

This means that if you use this draft to write a compare and contrast paper, each characteristic will be introduced in a separate paragraph.

Hydrophobic interaction chromatography (HIC)

This is based on the principle of weak hydrophobic interactions between the hydrophobic ligands (alkyl, aryl side chains on matrix) and hydrophobic amino acids of proteins. The differences in the composition of hydrophobic amino acids in proteins can be used for their separation. The elution of proteins can be done by lowering the salt concentration, decreasing the polarity of the medium or reducing the temperature.

Affinity chromatography

The ligand can be a specific antibody, substrate, substrate analogue or an inhibitor. The immobilized ligand on a solid matrix can be effectively used to fish out complementary structures.

This is an elegant method for the purification of proteins from a complex mixture. Affinity chromatography is based on an interaction of a protein with an immobilized ligand.

Ion-exchange chromatography

The ionic bound molecules can be eluted from the matrix by changing the pH of the eluant or by increasing the concentration of salt solution. Ion-exchange chromatography is useful for the purification of antibiotics, besides the purification of proteins.

In ion-exchange chromatography, the pH of the medium is very crucial, since the net charge varies with pH. In other words, the pH determines the effective charge on both the target molecule and the ion-exchanger.

It involves the separation of molecules based on their surface charges. Ion-exchangers are of two types (cation- exchangers which have negatively charged groups like carboxymethyl and sulfonate, and anion- exchangers with positively charged groups like diethylaminoethyl (DEAE).

Gel-filtration chromatography

At the industrial scale, gel-filtration is particularly useful to remove salts and low molecular weight compounds from high molecular weight products.

The smaller molecules enter the gel beads through their pores and get trapped. On the other hand, the larger molecules cannot pass through the pores and therefore come out first with the mobile liquid

The sponge-like gel beads with pores serve as molecular sieves for separation of smaller and bigger molecules. A solution mixture containing molecules of different sizes (e.g. different proteins) is applied to the column and eluted.

How is the movie different from the novel?

Type in a short explanation. Use 'like', 'same as' or 'similar' for comparison, and 'unlike', 'differ from' and 'although' for contrasting.

This is also referred to as size-exclusion chromatography. In this technique, the separation of molecules is based on the size, shape and molecular weight.

How is the novel different from the movie?

Type in the answer. Use 'like', 'same as' or 'similar' for comparison, and 'unlike', 'differ from' and 'although' for contrasting.

Formulation

The introduction provides background information for both the book and the movie.

Drying

Drying is an essential component of product formulation. It basically involves the transfer of heat to a wet product for removal of moisture. Most of the biological products of fermentation are sensitive to heat, and therefore require gentle drying methods. Based on the method of heat transfer, drying devices may be categorized as contact, convection, radiation dryers. These three types of dryers are commercially available.

Freeze-drying:

Freeze-drying or lyophilization is the most preferred method for drying and formulation of a wide-range of products—pharmaceuticals, foodstuffs, diagnostics, bacteria, viruses. This is mainly because freeze-drying usually does not cause loss of biological activity of the desired product.

Spray drying:

Spray drying is used for drying large volumes of liquids. In spray drying, small droplets of liquid containing the product are passed through a nozzle directing it over a stream of hot gas. The water evaporates and the solid particles are left behind.

Is the action in the movie set in the same place?

Where is it set? Example: The action in Great Expectations (1946) by David Lean has the same setting as in the book.

Concentration

Restate your thesis while avoiding repetition.

Adsorption

And for concentration of low molecular weight compounds (vitamins, antibiotics, peptides) polystyrene, methacrylate and acrylate based matrices are used. The process of adsorption can be carried out by making a bed of adsorbent column and passing the culture broth through it. The desired product, held by the adsorbent, can be eluted.

The biological products of fermentation can be concentrated by using solid adsorbent particles. In the early days, activated charcoal was used as the adsorbent material. In recent years, cellulose-based adsorbents are employed for protein concentration.

Precipitation

Precipitation is the most commonly used technique in industry for the concentration of macromolecules such as proteins and polysaccharides. Further, precipitation technique can also be employed for the removal of certain unwanted byproducts e.g. nucleic acids, pigments.

Membrane Filtration

Membrane filtration has become a common separation technique in industrial biotechnology. It can be conveniently used for the separation of biomolecules and particles, and for the concentration of fluids. The membrane filtration technique basically involves the use of a semipermeable membrane that selectively retains the particles/molecules that are bigger than the pore size while the smaller molecules pass through the membrane pores.

Liquid-Liquid Extraction

Restate the differences between the book and the movie.

The concentration of biological products can be achieved by transferring the desired product (solute) from one liquid phase to another liquid phase, a phenomenon referred to as liquid-liquid extraction. Besides concentration, this technique is also useful for partial purification of a product. The process of liquid-liquid extraction may be broadly categorized as extraction of low molecular weight products and extraction of high molecular weight products.

Extraction of high molecular weight compounds:

Proteins are the most predominant high molecular weight products produced in fermentation industries. Organic solvents cannot be used for protein extraction, as they lose their biological activities. They are extracted by using an aqueous two-phase systems or reverse micelles formation.

Reverse miceller systems:

Reverse micelles are stable aggregates of surfactant molecules and water in organic solvents. The proteins can be extracted from the aqueous medium by forming reverse micelles. In fact, the enzymes can be extracted by this procedure without loss of biological activity.

Aqueous two-phase systems (ATPS):

They can be prepared by mixing a polymer (e.g., polyethylene glycol) and a salt solution (ammonium sulfate) or two different polymers.

Extraction of low molecular weight products:

By using organic solvents, the lipophilic compounds can be conveniently extracted. However, it is quite difficult to extract hydrophilic compounds. Extraction of lipophilic products can be done by the following techniques.

Supercritical fluid (SCF) extraction:

This technique differs from the above procedures, since the materials used for extraction are supercritical fluids (SCFs). SCFs are intermediates between gases and liquids and exist as fluids above their critical temperature and pressure. Supercritical CO2, with a low critical temperature and pressure is commonly used in the extraction.

Reactive extraction:

In this case, the desired product is made to react with a carrier molecule (e.g., phosphorus compound, aliphatic amine) and extracted into organic solvent. Reactive extraction procedure is quite useful for the extraction of certain compounds that are highly soluble in water (aqueous phase) e.g., organic acids.

Dissociation extraction:

This technique is suitable for the extraction of ionisable compounds. Certain antibiotics can be extracted by this procedure.

Physical extraction:

The compound gets itself distributed between two liquid phases based on the physical properties. This technique is used for extraction of non-ionising compounds.

Evaporation

Restate the similarities between the novel and the movie, but try to avoid repetition (this will help if you write an essay afterward).

The evaporators, in general, have a heating device for supply of steam, and unit for the separation of concentrated product and vapour, a condenser for condensing vapour, accessories and control equipment. The capacity of the equipment is variable that may range from small laboratory scale to industrial scale.

Centrifugal forced film evaporators:

These equipment evaporate the liquid very quickly (in seconds), hence suitable for concentrating even heat-labile substances. In these evaporators, a centrifugal force is used to pass on the liquid over heated plates or conical surfaces for instantaneous evaporation.

Forced film evaporators:

The liquid films are mechanically driven and these devices are suitable for producing dry product concentrates.

Falling film evaporators:

In this case, the liquid flows down long tubes which gets distributed as a thin film over the heating surface. Falling film evaporators are suitable for removing water from viscous products of fermentation.

Plate evaporators:

The liquid to be concentrated flows over plates. As the steam is supplied, the liquid gets concentrated and becomes viscous.

Release of Intracellular Products

Cell Disruption

Enzymatic methods

Certain other enzymes are also used, although less frequently, for cell disruption. For the lysis of yeast cell walls, glucanase and mannanase in combination with proteases are used.

For Gram-negative bacteria, lysozyme in association with EDTA can break the cells. As the cell wall gets digested by lysozyme, the osmotic effects break the periplasmic membrane to release the intracellular contents.

Lysozyme is the most frequently used enzyme and is commercially available (produced from hen egg white). It hydrolyses β-1, 4-glycosidic bonds of the mucopeptide in bacterial cell walls. The Gram- positive bacteria (with high content of cell wall mucopeptides) are more susceptible for the action of lysozyme.

Cell disruption by enzymatic methods has certain advantages i.e., lysis of cells occurs under mild conditions in a selective manner. This is quite advantageous for product recovery.

Chemical methods

Detergents:

Detergents that are ionic in nature, cationic-cetyl trimethyl ammonium bromide or anionic-sodium lauryl sulfate can denature membrane proteins and lyse the cells. Non-ionic detergents (although less reactive than ionic ones) are also used to some extent e.g., Triton X-100 or Tween.

Organic solvents:

Several water miscible organic solvents can be used to disrupt the cells e.g., methanol, ethanol, isopropanol, butanol. These compounds are inflammable; hence require specialised equipment for fire safety.

Alkalies:

Alkali treatment has been used for the extraction of some bacterial proteins. However, the alkali stability of the desired product is very crucial for the success of this method e.g., recombinant growth hormone can be efficiently released from E. coli by treatment with sodium hydroxide at pH 11.

Physical methods

Grinding with glass beads:

The cells mixed with glass beads are subjected to a very high speed in a reaction vessel. The cells break as they are forced against the wall of the vessel by the beads.

Impingement:

In this procedure, a stream of suspended cells at high velocity and pressure are forced to hit either a stationary surface or a second stream of suspended cells (impinge literally means to strike or hit). The cells are disrupted by the forces created at the point of contact.

High pressure homogenization:

This technique involves forcing of cell suspension at high pressure through a very narrow orifice to come out to atmospheric pressure. This sudden release of high pressure creates a liquid shear that can break the cells

Heat shock (thermolysis):

Breakage of cells by subjecting them to heat is relatively easy and cheap. But this technique can be used only for a very few heat-stable intracellular products.

Osmotic shock:

This method involves the suspension of cells (free from growth medium) in 20% buffered sucrose. The cells are then transferred to water at about 4°C. Osmotic shock is used for the release of hydrolytic enzymes and binding proteins from Gram-negative bacteria.

Ultra sonication:

Ultrasonic disintegration is widely employed in the laboratory. However, due to high cost, it is not suitable for large-scale use in industries.

Solid-Liquid Separation

Centrifugation

The technique of centrifugation is based on the principle of density differences between the particles to be separated and the medium. Thus, centrifugation is mostly used for separating solid particles from liquid phase (fluid/particle separation). Unlike the centrifugation that is conveniently carried out in the laboratory scale, there are certain limitations for large scale industrial centrifugation.

Scroll centrifuge or decanter:

It is composed of a rotating horizontal bowl tapered at one end. The decanter is generally used to concentrate fluids with high solid concentration (biomass content 5-80%). The solids are deposited on the wall of the bowl which can be scrapped and removed from the narrow end.

Multi-chamber centrifuge:

This is basically a modification of tubular bowl type of centrifuge. It consists of several chambers connected in such a way that the feed flows in a zigzag fashion. There is a variation in the centrifugal force in different chambers. The force is much higher in the periphery chambers, as a result smallest particles settle down in the outermost chamber.

Disc centrifuge:

It consists of several discs that separate the bowl into settling zones. The feed/slurry is fed through a central tube. The clarified fluid moves upwards while the solids settle at the lower surface.

Tubular bowl centrifuge:

This is a simple and a small centrifuge, commonly used in pilot plants. Tubular bowl centrifuge can be operated at a high centrifugal speed, and can be run in both batch or continuous mode. The solids are removed manually.

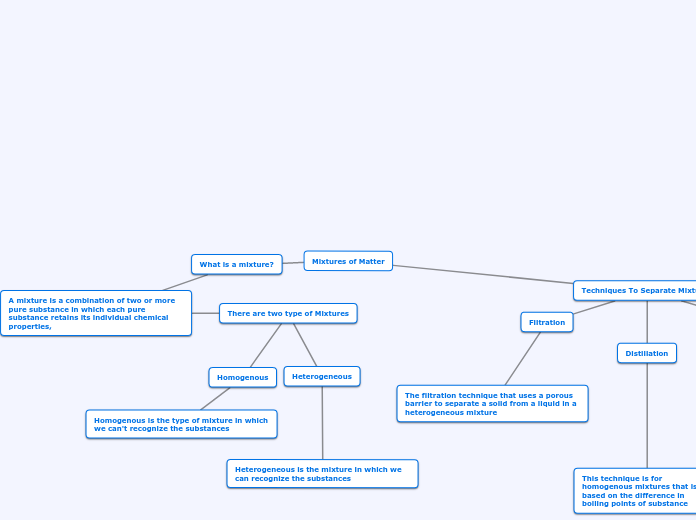

Filtration

There are 3 major types of filtrations based on the particle sizes and other characters . These are microfiltration, ultrafiltration and reverse osmosis.

Several filters such as depth filters, absolute filters, rotary drum vacuum filters and membrane filters are in use.

Membrane Filters:

In this type of filtration, membranes with specific pore sizes can be used. There are two types of membrane filtrations—static filtration and cross-flow filtration. In cross-flow filtration, the culture broth is pumped in a crosswise fashion across the membrane. This reduces the clogging process and hence better than the static filtration.

Rotary Drum Vacuum Filters:

These filters are frequently used for separation of broth containing 10-40% solids (by volume) and particles in the size of 0.5-10µm. Rotary drum vacuum filters have been successfully used for filtration of yeast cells and filamentous fungi.

Absolute Filters:

These filters are with specific pore sizes that are smaller than the particles to be removed. Bacteria from culture medium can be removed by absolute filters.

Depth Filters:

They are composed of a filamentous matrix such as glass wool, asbestos or filter paper. The particles are trapped within the matrix and the fluid passes out. Filamentous fungi can be removed by using depth filters.

The efficiency of filtration depends on many factors— the size of the organism, presence of other organisms, viscosity of the medium, and temperature.

Filtration is the most commonly used technique for separating the biomass and culture filtrate.

Flocculation

Addition of flocculating agents (inorganic salt, organic polyelectrolyte, mineral hydrocolloid) is often necessary to achieve appropriate flocculation.

The process of flocculation depends on the nature of cells and the ionic constituents of the medium.

In flocculation, the cells (or cell debris) form large aggregates to settle down for easy removal.

Flotation

The presence of certain substances, referred to as collector substances, facilitates stable foam formation e.g., long chain fatty acids, amines.

When a gas is introduced into the liquid broth, it forms bubbles. The cells and other solid particles get adsorbed on gas bubbles. These bubbles rise to the foam layer which can be collected and removed.