RFP1 HEATING

SEC IB:

GAS FITTING CODES

PART "B"

Location

- Do not install gas pipes

- under stiarwells (other than residential)

- inside chimneys

- inside elevator shafts

- HVAC ducts (other than return air ceiling spaces)

- in contact with ashes or corrosive materials

- Do not install in concealed locations where corrosive fumes may be present... if so, use ventilation methods

When installing in concrete floors:

- Encase in a duct with holes at both ends

- Can use a trench with a non sealed cover

Purging

Testing

- All gas installations require a permit be obtained before the work is carried out.

- After the installation is completed, the gas line must be pressure-tested and inspected.

- Concealed installations cannot be closed in until after the inspection is completed.

- Can be air, CO2, Nitrogen or any other inert gas

- pressure gauge used in the test is required to be a minimum 3" (75 mm) and must be calibrated in increments of 2 psig (14 kPa) or 2% of the maximum dial reading, whichever is greater

- Install a pressure gauge or manometer at the dirt pocket of one appliance.

- Charge the system, turn the gas supply off and watch the test dial for ten minutes.

- If there are no leaks, leak-test the finish piping and appliance valve train with the appliance operating

- Any addition that is less than 20 ft (6 m) in total length and has a gas pressure below 0.5 psig (3.5 kPa) can be leak-tested rather than pressure-tested

- After the gas line is approved and the appliances are connected, the finish piping must be tested

- The installer must first check that all openings in the gas line are capped off or closed. After turning on the gas supply, watch the test dial of the gas meter or if there is no gas meter, a pressure gauge or manometer can be installed and watched to ensure that no gas is leaking from the system;

Coated Pipe

- Factory-wrapped or coated pipe or tubing is required to have a minimum of 100 psig (700 kPa) pressure test

Installation

Inspection

Roof Top Piping

- Steel gas lines installed on a rooftop must be painted and not yellow jacketed.

- Rooftop installations must allow for expansion and contraction of the gas piping materials.

- Support of gas piping installed on roofs must be in the form of treated wood blocks

Emergency Generators

- The gas supply to the generator must be separate from the building gas supply so that if one is shut off it will not affect the other.

Gas Hoses

- Vented appliances cannot be connected to the gas supply with hoses.

- Hose may be used to connect portable appliances or appliances that require isolation from vibration.

- Connectors shall be protected from damage, shall not pass through a wall, floor, ceiling or partition, and shall be connected to rigid piping located in the same area as the appliance

Shutoff Valves

- Manual shut-off valves shall be rated for the service conditions to which they will be subjected.

- An accessible shut-off valve (gas cock) shall be installed in the drop or riser as close to the valve train as possible for each industrial and commercial type appliance.

- Preferred piping practice is to install the gas cock in the drop or riser, as this allows for the dirt pocket to be emptied and to be used for taking manometer pressure tests.

- a gas cock to an individual gas appliance for residential purposes may be located up to 50 ft (17 m) away from the appliance as long as it is accessible and clearly tagged. (fireplaces especially)

- Whenever piping or tubing extends from one building to another, approved shut-off valves must be installed where the pipe leaves the first building and where it enters the second building.

- Risers connected to propane storage tanks require shut-off valves to be installed on each riser.

Pipe Identification

- All building piping in commercial and industrial applications requires identification.

- painted yellow, banded yellow or the piping can be marked or labelled "Gas"

- Copper pipe needs to be marked every 6 feet of pipe length

- For commercial buildings, steel pipe must be marked every 20 ft (6m)

- Steel pipe in residential installations need not be marked.

Pipe Protection

- Painting or coating will protect any gas line that is exposed to atmospheres that are corrosive.

- Steel pipe is usually PVC or PE coated (yellow jacket)

- Copper tubing, Type L, is coated with PVC or PE resin

- Type K copper requires no special coating

- Steel and plastic gas lines require the installation of insulating unions at each end to ensure that no galvanic action is transmitted to or from the building piping.

- Gas lines must be located free from the arc of all building doors and appliance service doors and covers.

- At any point where a gas line passes through a concrete or brick wall, the gas line shall be protected from the corrosive effects of the concrete by sleeving or double wrapping.

- Exterior penetrations must also be watertight.

- Steel gas lines installed on a rooftop must be painted and not yellow jacketed.

- Underground piping or tubing must have sufficient cover to prevent damage to the gas line.

- Never be less than 15" (400 mm).

- Piping must rise above grade level before entering the building

- Gas lines installed under a commercial driveway will require 24" (600 mm)

- Where the pipe or tubing rises above grade, protection from physical damage must be provided; in addition to this, a sleeve should be installed around the gas pipe.

- If concrete or paving is to be placed over the gas line a sleeve must be installed to allow the paving to settle without placing strain on the gas riser.

When such paving extends 25 ft (7.5 m) or more horizontally over the gas line, a vent pipe/inspection point (Figure 15) shall be installed so leaks in the underground piping can be detected.

- Piping cannot go under a foundation wall or footing.

- In no case shall an underground gas line be threaded

- Underground gas pipe no smaller than 1/2"

- PLASTIC PIPE

- Plastic line should be snaked side to side in the trench without vertical slack loops and at bends should be kept to the outside radius.

- The gas supply to plastic piping or tubing requires a shut-off valve installed in the line above ground.

- All plastic gas lines must have a tracer wire or equivalent attached to it prior to placing it in the trench

Prohibited Practices

Close Nipples

- Close nipples have no shoulder and may screw too far into one fitting.

- They are prohibited

Street Elbows

- Street fittings contain both male and female threads.

- Street elbows are not allowed

Field Bending of Pipe

Pipe may be bent on the job site as long as proper equipment is employed.

Nesting of Bushings

- You cannot install one bushing inside of another.

Defective Piping

Unions and Swing Joints

- They loosen over time and need to be accessible for inspection and adjustment

Electrical Bonding

- Gas pipe must be bonded to an approved ground to eliminate static build up and to dissipate electrical charges that may accidentally develop

Drip & Dirt Pockets

- A drip pocket is designed to collect condensate that forms in the pipe, due to conditions such as extreme temperature change.

- A drip pocket will be located wherever condensate will collect, such as the traps created when the gas line dips under a beam and back up again.

- Dirt Pockets are designed to collect scale, filings and foreign materials that may be present in the gas line before they reach the appliance. Dirt pockets are located in the gas pipe at the bottom of the final drop to an appliance.

Appliance Connections

- Quick disconnects (quick couplers) may be used on appliance connections if a shut-off valve (gas cock) is installed upstream of the quick coupler

- The gas cock must be accessible and as close as possible to the quick coupler.

- If the appliance is not connected, the outlet should be capped and left in a safe manner.

Branch Piping

If a future takeoff is to be installed in a gas line and the size cannot be determined, the branch must be the same size as the pipe that serves it. W

Pipe Joints

- All pipe that is larger than 2" NPS must be welded.

- must be performed by a qualified welder holding a B pressure ticket.

Subtopic

Copper

- Joints made in tubing of copper, brass or steel can utilize flare fittings

- Can be brazed with a material with a melting point above 1000°F (525°C).Brazing material containing phosphorus is not recommended for use as brazing materials, as sulphur would attack the brazing material.

- Can be joined by an approved compression fitting (Swagelok or Gyrolok)

Gaskets

- May not be natural rubber, as the gas tends to dissolve and break down the gasket.

- All gaskets shall be synthetic materials or cork.

Bushings

Pipe Dope

- Pipe dope must also be approved for the pressure requirement of high-pressure gas installations.

- Pipe dope must be applied to the male (pipe) threads only, so that excess dope is forced out of the pipe instead of pushed into the pipe

Teflon Tape

- Teflon tape products also require certification for use with gas pipe . The thin white Teflon tape used for plumbing is not approved for gasfitting. Use yellow, pink, light orange or light green

- Teflon tape must be applied by wrapping it clockwise, stretching it with a 50% overlap and leaving the first two starter threads bare.

- Do not over tighten

Fittings

- Fittings used in welded pipe installations must be manufactured, not field-fabricated. For ipe larger than 2 -1/2", an exception is made

Supports

- Piping needs to be supported. There is a table in the code book to give dimensions

- Rigid pipe should not be strapped directly to or drilled through the floor joists (if a joist settles it will put stress on the pipe and fittings). The preferred practice is to suspend the pipe at least one inch below any framing structure.

- Engineered members such as truss joists have strict guidelines as to where, how many and what size holes may be drilled into them.

- Copper tubing or the newer corrugated stainless steel tubing (CSST) materials may be strapped directly to or drilled through joists and other structural members

- CSST manufacturers require that all installers attend and pass an installation course before the product will be sold to them.

Wood framing

- Holes must be located a minimum of 2 inches (50 mm) from any edge of a member in wood framing.

- Tubing runs inside walls or partitions within 13 /4" of the surface shall be protected from puncture at the stud and plate penetration points by the use of protection plates that have a minimum thickness of number 16 gauge plates

Size

- Capable of supplying sufficient gas pressure to all of the appliances served by the gas line.

- Gas pressure that is too low will cause under-firing and poor combustion, possibly creating the formation of carbon monoxide (CO) and damage

- gas pressure that is too high will cause over-firing, incomplete combustion and possibly damage to the appliance components.

- The maximum allowable pressure drop on a low-pressure (7 to 14 inch w.c.) gas line system is l" w.c. and on a high-pressure system (above 14 inch w.c.), is 50% of standing pressure.

Extensions

- Size the addition to meet the load requirement. When the addition is connected to the existing piping or tubing, the existing gas line must be large enough to handle the increased load

- When the existing gas line is too small, the new gas line may be connected to the existing piping within two ft (600 mm) of the gas meter (Natural Gas)

- For propane, the connection wmus be within 600mm of the regulator

Material

Steel, copper or plastic piping or tubing may be used for the installation of gas systems (plastic is only used for outdoors underground).

When used materials are to be reused in an installation, it is the responsibility of the installer to ensure that the used materials are equivalent to new materials and that the used materials have been inspected and tested. In addition, the used materials must have only been previously used for gas.

Tubing

- seamless copper or steel

- Corrugated stainless steel tubing (CSST) is not classified as tubing; it is classified and rated as pipe.

- Copper tubing must be certified under the listed standards and shall be type G, L or K.

- Copper tubing laid underground can be type G or L if it is coated with an extruded PVC or polyethylene resin at the time of manufacture; otherwise, type K shall be used.

- Aluminium tubing is not acceptable as a gas piping material, but is allowed to be used on appliances for pilot gas tubing and vent lines.

- Tubing used for venting regulators or gas valves may be steel, copper or if it is on or inside the appliance, aluminum.

- If a vent line is to terminate next to a continuous burning pilot flame (as with a diaphragm gas valve), the tubing shall be capable of withstanding the high temperatures involved (steel tubing is usually used for this purpose).

- Tubing fittings must be rated for a minimum of 125 psig

- Hose and hose fittings minimum pressure rating of 350 psig (2400 kPa).

Plastic

- Polyethylene (PE)

- only for outdoor underground installations

- may not be used for liquid propane and it cannot be used for the first 10 ft (3 m) from the outlet of a vaporizer

Pipe

- Black steel pipe only

- ... or Corrugated stainless steel tubing (CSST) is not classified as tubing; it is classified and rated as pipe.

- Schedule 40 to 125 psig (860 kPa) if the joints are threaded

- More than 125 psig (860 kPa) if the joints are welded or flanged

- Schedule 80 pipe may be used for all applicable pressures,

- Fittings installed in a gas piping system must be malleable iron or steel

- Fittings and pipe threads must conform to the applicable standard and are known as National Pipe Thread (NPT) or American Standard Pipe Thread (ASPT).

SEC IA:

GAS FITTING CODES

PART "A"

Terminiology

Power Burner

A burner that is equipped with a mechanical device to supply combustion air.

LPG

liquefied petroleum gases.

Pressures

Standing Pressure

The pressure in the gas line when gas is flowing only to the pilot burner. The connection point for the manometer is downstream of the service regulator and immediately upstream of the appliance regulator.

Operating Pressure

The pressure in the gas line when gas is flowing to the pilot and main burner(s). In other words, when the appliance is operating. The connection point for the manometer is downstream of the service regulator and immediately upstream of the appliance regulator.

Manifold Pressure

- The pressure in the appliance manifold when the appliance is operating.

- The connection point for the manometer is downstream of the appliance regulator, or at a tapping directly on the manifold.

Line Pressure

The pressure in the gas line when NO gas is flowing. The service regulator will lock up, causing a slightly higher pressure than the standing pressure.

High Pressure

Gas pressures above 14 inches (350 mm) of water column, or 0.5 psig (3.50 kPa)

Low Pressure

Gas pressures up to and including 14 inches (350 mm) of water column, or 0.5 psig (3.50 kPa).

Flame

Soot

Carbon in the fuel that has not been completely burned, leaving a solid residue.

Oxidizing Flame

A flame that is rich in oxygen (air) and having a hard, sharp, predominately blue appearance.

Neutral Flame

A flame that is neither rich in fuel (gas) nor oxygen (air)

Lift Off

A condition in which the gas/air mixture speed exceeds the flame speed to the extent that the flame is forced off the burner.

Impinge

To encroach or to touch. When a flame impinges on a combustion chamber, the flame touches the combustion chamber

Flashback

A condition in which the flame speed exceeds the gas/air mixture speed and the flame burns back inside the burner to the orifice.

Flashpoint

The minimum temperature at which a substance has reached a sufficient concentration to form an ignitable mixture with air.

Flame Speed

Also known as flame propagation. The speed at which a flame will burn along a stationary column of air/gas mixture.

Flame Rollout

A condition in which the flames at the burner are caused to exit the combustion chamber openings for the burner.

Piping

Yellow Jacket

Plastic (PVC or PE) coating applied to steel pipe and that offers corrosion protection for buried gas pipe.

Secondary Service

Underground gas piping within a customer's yard site. From the outlet of the meter to various outbuildings

Union

- A fitting containing two female threaded halves and a collar that holds them together.

- The union is used as the final connection in a piping system serving an appliance.

- The use of a union eliminates the need for left- and right-handed threaded fittings.

Swing Joing

A

three-elbow threaded piping configuration to allow for pipe movement when piping is travelling through the ground and up into a structure such as a building

Service Pipe

The portion of the gas distribution system that extends from the gas main located in the street and terminates at the outlet of the gas meter.

Rough Piping

- All gas piping or tubing that, after installation, is pressure�tested and inspected.

- In general terms, the gas piping that extends from the gas meter and terminates at the appliance gas cock or shutoff valve.

- This section of piping is subject to a pressure test and inspection.

PE Piping

Polyethylene gas piping. The only approved plastic gas piping. For use on underground systems only.

Gas Cock

Usually considered to be a quarter turn tapered plug valve without an attached handle

Finish Piping

All of the gas piping or tubing that is installed to connect the appliance to the gas line downstream of the appliance shutoff valve. This portion of the piping is not included in the initial pressure test, and will be tested as per 6.22.3.

Drop

That portion of the gas line that extends down vertically from the gas line to connect the appliance. The drop usually includes a gas cock and dirt pocket.

Complete Combustion

The uniting of gas with the oxygen in the air whereby all of the hydrogen and carbon in the fuel is converted to water and carbon dioxide respectively.

Carbonizing Flame

Also called a carburizing flame, this is a flame that is rich in fuel (gas), has a soft, lazy appearance and is predominately yellow.

Calorific Value

The number of BTUs contained in a specific volume of a fuel gas. The volume is generally stated in cubic feet.

Units

STP

Standard Temperature and Pressure (STP)

All comparisons are made at this standard. Standard temperature is 60°F, while standard pressure is atmospheric pressure at sea level (14.7 psia).

MMBH

An acronym meaning millions of BTUs per hour

MBH

An acronym meaning thousands of BTUs per hour

Gigajoule

A gas volume measurement in relation to cubic feet. Utility companies will use the gigajoule for billing purposes.

BTU

An acronym meaning British Thermal Unit. This is the amount of heat energy required to raise the temperature of one pound of fresh water by one degree Fahrenheit.

Air Supply

Air required for the proper operation of a gas-burning appliance; this includes primary air, secondary air, excess air, dilution air and ventilation air.

Know How much primary air, excess air and secondary air...

Dilution Air

Dilution Air

The ambient air that is admitted to a venting system at a draft control device.

Excess Air

xcess Air

That portion of the combustion air that is supplied to the zone of combustion in excess of that which is theoretically required for complete combustion.

Theoretical Air

Theoretical Combustion Air

The air required for the complete combustion of a fuel gas. This air is the theoretical amount of primary air and secondary air. Approximately 60 % of the air is used as primary air and 40% as secondary air.

Secondary Air

The portion of the combustion air that is supplied downstream from the point of combustion for the intermediate and final stages of the combustion process.

Primary Air

That portion of the combustion air that is supplied upstream from the point of combustion for the initial stages of the combustion process.

Aldehydes

A component of incomplete combustion. This component can be detected by its acrid odour, which will sting the eyes and mucous membranes.

General Rules

Underground Piping

- An approved transition fitting shall be used for connecting piping or tubing of either steel, or copper to plastic.

- A mechanical compression fitting shall not be located within 15 ft (4.5 m) of a building.

Pipe Bending

Bending of gas piping shall be made only with bending equipment and procedures especially intended for that purpose.

Installer Responsibilities

- Always read the manufacturer's instructions before installing an appliance or component.

- Only certified gas appliances may be installed. The appliance will have proof of approval on the rating plate.

Responsibilities of the Installer:

- The installer is responsible for ensuring that all appliances, as well as components or accessories that they install, meet the code requirements, perform the function(s) they were designed for and are installed in a safe working order.

- The installer is the person who connects the gas to the appliance...

- The person who commissions it, or the last person to work on it becomes responsible for the appliacne.

- All instruction and installation booklets that are supplied with a gas appliance must be left with the appliance.

- Poor workmanship is reason enough to fail the inspection.

- Manufacturers of appliances and equipment may employ their own service personnel and will train those people to perform the required service

Mobile Homes

Mobile homes need to use furnaces that are certified specifically for use in mobile homes...

If you take the mobile home and put it on a permanent foundation... you can use any furnace...doesnt need to be specifically designed for mobile homes.... (because it is no longer mobile)

Safety Devices

Safety devices, such as high limits or safety shut-off, must not be removed or rendered inoperative.

Defective Heat Exchangers

- Heat exchangers in residential appliances must be replaced if found to be defective

- There is a provision to achieve temporary repairs if the Safety Codes Officer must approves

- Heat exchangers on commercial appliances may be repaired, but the repair must meet the approval of the Safety Codes Officer.

- permits may be required

High Altitude Installation

- Elevation between 2000 feet and 4500 feet (600 and 1300 m) above sea level.

- Appliances installed at these elevations must be approved and certified for installation at these elevations.

- All of Alberta is classified as high altitude

Odorization of Propane

Leak Detection

- Soapy Water

- Electronic Detector

- No open flames

Hazardous Locations

The Code prohibits the installation of gas appliances in locations where the potential for damage to life, property and to the appliance caused by fire and explosion hazards.

Electrical Connections

- All field wiring connected to an appliance shall conform to the applicable Electrical Code and shall be performed by qualified personnel only.

- You may work on electrical components of an appliance and you are limited to low voltage as described by the Electrical Code.

- This limits you to a maximum of 150 volts AC and a maximum of 1 amp of current draw.

- Any wiring replaced or repaired on an appliance must conform to the manufacturer's wiring diagrams.

- Ground circuits must not utilize any portion of the gas line, unless for a low voltage signal, such as those designed for proving flame (flame rectification)

Meter and Regulator Installations

- Gas services, service regulators and meters are the property of the gas utility and are to be installed and serviced by the utility's personnel or authorized agents.

- Only the utility company installs, services and adjusts the service regulator which is usually set at 7 inch water column (w.c.) on a residential natural gas installation.

Propane

The Gasfitter is responsible for the installation and servicing of the first-stage regulator and second-stage regulator only on a propane gas line service.

As the installer, you are responsible for the installation, servicing and setting of the first-stage and second-stage regulators on a propane installation. First-stage regulators are usually set at 10 psig and second-stage regulators are set at 11 inch w.c

- Propane must be odorized before it reaches the final consumer. It is the responsibility of the producer of the propane to ensure that this requirement is met.

Access to equipment

An appliance shall not be installed on a roof of a building exceeding 13 ft (4 m) in height from grade to roof elevation unless access is provided in accordance with the Alberta Building Code.

Gasfitters

- We are Refrigeration Mechanics, not Gasfitters.

- We can service equipment up to a maximum of 400,000 BTUH.

- We do no piping

- You should know all of the fittings on this diagram below. The first one is Natural Gas

- This is a Propane installation

SEC K

PROPERTIES OF GAS AND COMBUSTION

CALORIFIC VALUES OF LIQUIDS (NOT GASES)

BTU PER POUND

CALORIFIC VALUES OF GASES (NOT LIQUIDS)

Combustion

Carbon Monoxide Poisoning

- Do not assume if a customer calls you and advises that they smell gas that it is natural gas

- It may also be aldehydes and carbon monoxide could be present in the home.

- 50 PPM (parts per million) is the allowable exposure for 8 hours

- 4000 PPM is fatal in less than 1 hour

Incomplete Combustion

Incomplete Combustion

- In order to obtain complete combustion, enough air must be supplied to the burning process.

- If not enough air is supplied, incomplete combustion will take place that will resulting the formation of additional products.

- Some of these products are harmful, especially carbon monoxide (CO).

- If there is not enough air supply, Carbon Monoxide (CO) and Soot (C) are produced as well

- Aldehydes may also be present and can be detected by their sharp penetrating odour.

- Yellow Flame indicates incomplete combustion

- Poor appliance venting can also cause incomplete combustion.

- Draft hood spillage will cause products of combustion to enter the room rather than going up the draft hood.

- The need for adequate air supply for safe and efficient appliance operation is very important.

Calculations

How much Theoretical air is required for a 70MBH Nat Gas furnace?

70,000 Btu / 1000 Btu/ft = 70 ft of gas (step one)

70 ft of gas x 10 ft of air (10:1 Ratio) = 700 ft of Theoretical Air

How much Excess air is required for a 70MBH Nat Gas furnace?

700 ft of Air x 40% = 280 ft

How much Total Combustion air is required for a 70MBH Nat Gas furnace?

700 ft of Air + 280 ft Excess air = 980 ft

Products of Combustion

Products of Combustion

Combustion air: The theoretical volume of air required to burn the gas completely.

Excess Air:

- In addition to this theoretical amount of air required, a percentage of Excess Air must be added to the process, because supplying only the theoretical amount of air will give incomplete combustion in a conventional gas fired appliance

- 40% Excess Air is required to ensure complete combustion

***IMPORTANT VISUAL SUMMARY***

Combustion Requirements

Combustion Requirements

- Combustion of a gas is a chemical reaction between fuel and oxygen.

- When hydrogen burns, water vapour is produced.

- The complete burning of carbon produces carbon dioxide.

- The symbol for carbon dioxide is CO2 and is formed by one atom of carbon and two atoms of oxygen.

Flame Liftoff

Flame Liftoff

- Flame Liftoff occurs when the air/gas mixture moves forward faster than the flame speed moves backwards.

- The flame is blown off or burns above the burner ports.

Flame Flashback

- Flame Flashback occurs when the air/gas mixture moves forward more slowly than the speed that the flame moves back.

- The flame flashes through the burner port and the gas burns at the orifice

Flame Temperature

Flame Temperature

- The maximum temperature reached inside the flame

- The hottest part of the gas flame is just above the tip of the inner cone

- The coolest part of the gas flame is at the base of the inner cone.

- Remember, 1 cu ft of Natural Gas will release 1000 BTU of Heat Energy.

- This will not change if the flame is burning normally, is carbonizing or is oxidizing…

- Burnt gas is burnt gas

Trade Calculations

Heat Calculation Theory

Everyone knows that it takes 1 BTU of energy to increase the heat 1 lb of fresh water by 1°F.

Specific heat is defined as the quantity of heat energy (in Btu) required to raise the temperature of one pound of a material by one-degree Fahrenheit. The specific heat of water is 1 Btu/lb-F, or one Btu per pound per degree Fahrenheit.

What is a Btu?

The amount of heat required to raise the temp of 1lb of water 1F

Specific heat of:

- Ice is 0.5 (BTU/lb) per °F

- Water is 1 (BTU/lb) per °F

- Steam is 0.46 (BTU/lb) per °F

Quantity of Heat

How many BTU’s are required to raise 1lb of water by 10F?

1 lbs x 1 BTU/lb x 10 = 10 BTU

How many BTU’s are required to raise 10 lbs of water by 10F?

10 lbs x 1 BTU/lb x 10 = 100 BTU

How much does 1 imperial gallon of water weigh?

10 lbs

How many BTUs are required to raise the temperature of 40 gallons of water from 130°F to 140°F?

40 gals x 10 lbs/gal x 1 (BTU/lb) / °F x 10 °F = 4000 BTU

BTU Calculations

Hot Water Tank

Everyone knows that it takes 1 BTU of energy to increase the heat 1 lb of fresh water by 1°F.

CALORIFIC VALUE OF GASES (NOT LIQUIDS)

Measured in BTU / Cu Foot

How many BTU’s would 5 ft of Natural gas produce?

5 cu ft x 1000 BTU/cu ft = 5000 BTU

A boiler is burning natural gas at a rate of 800,000 BTU every hour.

How many cu ft are burned in 1 hour?

800,000 BTU/hr ÷d 1000 BTU/ft - 800 cu ft

How many BTU’s are in one cubic foot of natural gas?

1000 BTU

How many BTU’s are in 10 cubic foot of natural gas?

10 cu ft x 1000 BTU/ft3 = 10,000 BTU

How many cu ft of natural gas is required to produce 100,000 BTU?

100,000 BTU ÷ 1000 BTU/cu ft = 100 cu ft

Propane Tank

CALORIFIC VALUE OF LIQUIDS (Measured in BTU per Pound)

Think about this when you are refilling your propane tank:

A standard 20lb propane tank is 4.5Gal

- How many BTU’s will it produce?

- How many hours will a BBQ last that is rated for 30,000 BTUH?

CALCULATED ANSWERS:

- 4.5 gals x 109560 BTU/Lb = 493,020 BTU

- This means that the BBQ will use up 30,000 BTU every hour that it operates. Since we determined that the stored heat energy in the tank (question 1 above) is 493,020 BTU and it burns 30,000 BTU every hours, then...

493,020 BTU ÷ 30,000 BTU/hr = 16.4 hrs

Calorific Values

CALORIFIC VALUES OF LIQUIDS (NOT GASES):

BTU PER POUND

CALORIFIC VALUES OF GASES (NOT LIQUIDS)

Propane Conversion

Converting a BBQ or Furnace to Natural Gas:

When converting a Natural gas appliance to Propane gas you must properly change the input rate because:

1 Cu Ft of Natural Gas produces 1000 BTUH and

1 cu Ft of Propane produces 2500 BTUH…

so your 30,000 BTUH BBQ would become a dangerous 75,000 BTUH BBQ

Gas Appliance Ratings

Gas Input Ratings:

- All gas appliances have a maximum input rating.

- It can never consume more than that maximum.

- As the gasfitter, you must verify that the appliance is operating at its maximum without going over.

BTU's and Heat Content

- Gas has stored energy waiting to be used, much the same way your body has stored energy (calories).

- The energy (calorific value) in gas is measured in BTU/cu ft.

- BTU is the amount of heat energy required to raise the temperature of one lb. of fresh water 1ºF.

CALORIFIC VALUES OF GASES (NOT LIQUIDS)

Specific Gravity

Specific Gravity

How many times the liquid is heavier or lighter than water.

It is also referred to as relative density.

Specific Gravity

Liquid Methane is 0.424

Liquid Propane is 0.51

The above means that the weight of liquid methane is 0.424 of that of water...

In other words if 1 lb of water weighs 1.0 lb, then liquid methane would weigh

0.42 x 1.0 = 0.424lbs

Density

- The relationship between the volume and the weight of a substance is called its density.

- If one imperial gallon (imp gal) (4.54 L) of water were weighed it would be 10 pounds (lb) (4.54 kg).

- To say the density of water is 10 or 10 lb would have no meaning.

- The correct way to describe the density of water is to say it is 10 lb per imperial gallon

Liquefied Petroleum Gas

Gas Chemistry

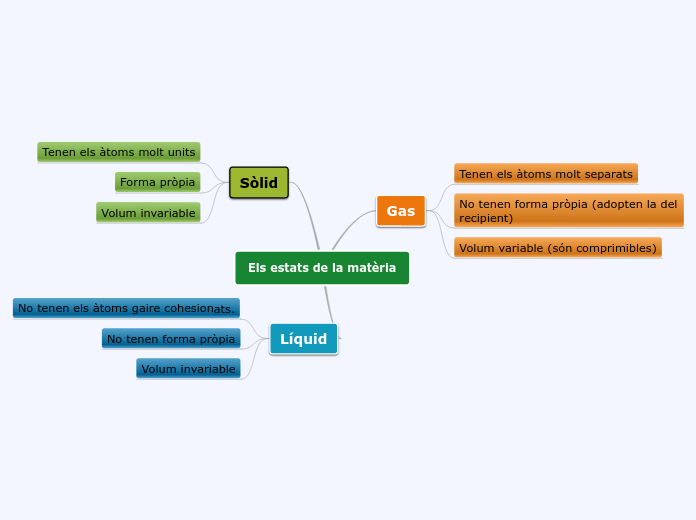

Properties of Matter

Matter can exist in four states:

- Solids

- Liquids

- Vapour

- Plasma.

Chemical Symbols

Acetylene

Butane

Butane:

Propane

Propane has an atmospheric pressure boiling point of –44ºF (–42ºC).

It expands 270 times as it changes state (liquification ratio)

Natural Gas

Natural gas, also known as methane, is made up of one atom of carbon and four atoms of hydrogen in every molecule.

- Fuel gases are composed of carbon and hydrogen atoms and are known as hydrocarbons.

- In gas fitting, you are concerned mainly with methane, propane and for comparison purposes, butane, acetylene and manufactured gas.

- Manufactured gas is not a true hydrocarbon as it is composed of several different gases in varying proportions.

Liquefied Petroleum Gas (LPG)

Liquefied Petroleum Gas

Hydrocarbons can be further sub-classified into liquefied petroleum gases (LPGs).

Natural gas requires an extremely low temperature or an excessively high pressure to cause it to turn to a liquid.

The common LPGs are propane and butane.

- You can see in the table that methane (Natural Gas) will change its state from a liquid to a vapour at –258°F

- This is not considered to be a normal temperature and you could not increase the boiling temperature with a moderate pressure change.

- If you look at propane and butane, they change their state from a liquid to a vapour at normal temperatures and you could increase the boiling temperatures by applying moderate pressure.

This is why methane (natural gas) is not considered to be an LPG.

The temperature at which a liquid converts to a gaseous state is the boiling point.

- Temperature changes the state of matter.

- Pressure will influence the temperature.

- When pressure increases, the boiling temperature will increase.

SEC J:

INTRODUCTION TO

GAS FITTING FUNDAMENTALS

Gas Codes

Pressure Testing Gas Train

Testing Valve Train (Manifold Piping)

- Appliance burner must be operating

- Connections tested with approved leak detector

Pressure Testing Finished Piping

Pressure Testing Finished (Connected) Piping

This is done when everything is hooked up.

Testing Finish Piping

- Min. 10 minutes

- Max. test pressure = working pressure only

- Test using manometer or smallest dial on gas meter

- Connections tested with approved leak detector

Pressure Testing Rough In Piping

All meters, appliances and regulators detached All outlets closed and capped or plugged. In other words... disconnect everything and only pressure test the gas line

Transmission of Propane

**Important**

- 1st stage regulator drops pressure to between 5-10 psi

- 2nd stage regulator drops pressure to 11” wc Manifold pressure is also set to 11” wc

- Propane runs at a higher pressure than natural gas because it is heavier and harder to push through the pipe.

Pressures at Furnace

Measuring Low Pressure

Gas pressures are measured in psi for higher pressures but given in W.C. (Inches of Water Column) for most residential and appliance applications

A column of water 1” square and 12” high will exert a pressure of .434 psi

1

1 psi = 28” WC

Once the gas reaches your house, the utility company reduces the pressure again down to 1/4 – 1/2 psig (7” – 14” water column) which is low pressure. Residential houses are allowed to have up to 2 psi in the building supply piping

Transmission Natural Gas

Pipeline companies (Enbridge, Trans mountain, etc.) do not own the gas, they are contracted to ship it to its destination. • Transmission pipelines run at 300psi – 1500psi

When local utilities receive gas from the gas processing plant: • They drop the pressure to 2psi – 80psi at the “City Gate” • Natural gas and Propane have an odorant, Mercaptan, added to provide an odour to them so they can be detected as they are colourless and odorless without

Natural Gas Storage

To ensure enough gas supply throughout winter, Natural gas is stored in salt caverns • Natural gas is pumped in and stored at a pressure of 4100psi during summer and drawn out during winter • Without salt caverns nat. gas needs to be chilled to -258F to be liquified for storage

Distribution

Water Removal

All Natural Gas contains Water which must be dealt with or it would freeze, forming hydrates 2 Methods Absorption – bubbling gas through a liquid desiccant (glycol solution) which absorbs the gas Adsorption – pass the gas over a bed of granular solids that attract the water. (ie silica

Exploration

Gas is trapped in porous formations beneath the earth Seismic animation on the left shows sound waves used to locate oil & gas formations The wet gas pocket that is harvested from the top of the oil is cleaned and refined into Natural gas and LPG gases by Fractionization

Hydrocarbons

The basic elements of oil, nat gas and coal are hydrogen and carbon. These are known as Hydrocarbons

Gasfitter

"B" Gas Fitter - Max they can work on is 400,000 BTUH

"A" Gas Fitter - No maximum, except utility and transmission systems.