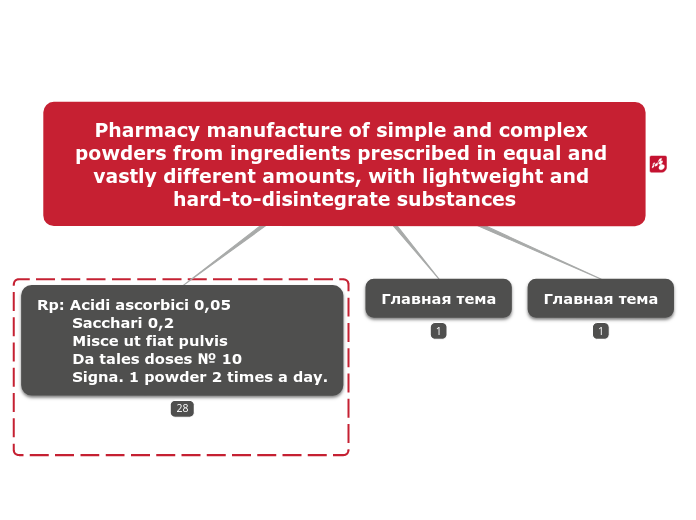

Pharmacy manufacture of simple and complex powders from ingredients prescribed in equal and vastly different amounts, with lightweight and hard-to-disintegrate substances

Главная тема

подтема

Rp: Acidi ascorbici 0,05

Sacchari 0,2

Misce ut fiat pulvis

Da tales doses № 10

Signa. 1 powder 2 times a day.

Characteristic of dosage form

Complex divided into doses (one-dose) powder for internal use is prescribed.

Powders – preparations consisting of solid, loose, dry particles of varying degrees of fineness. They contain one or more active substances, with or without excipients and, if necessary, colouring matter authorised by the competent authority and flavouring substances.

According to the dispersion classification powders are free disperse systems without a dispersion medium.

Powder is prescribed by distributive method.

Pharmaceutical substance - Acidum ascorbici, excipient – Saccharum.

Saccharum - white or almost white crystalline powder or shiny, colorless or white or almost white crystals. Very easily soluble in water, slightly soluble in 96% alcohol, almost insoluble in anhydrous ethanol

Acidum ascorbicum - white or almost white, crystalline powder or colourless crystals, becoming discoloured on exposure to air and moisture. Solubility: freely soluble in water, sparingly soluble in ethanol (96%).

Properties of substances for pharmaceutical use

Preparation of premises, personnel, pharmacy utensils, auxiliary materials and closures

In accordance with Sanitary norms and rules at the beginning of each shift scales, spatulas, scissors and other small pharmacy equipment should be treated with 3% solution of hydrogen peroxide or other means of disinfection (for example, alcohol-ether mixture). Glassware is washed and sterilized in compliance with the sterilization regime in accordance with Appendix 1 of Sanitary Norms and Regulations, sealed and stored in tightly closed cabinets no more than 3 days (for non-sterile dosage forms). Auxiliary materials, small pharmaceutical inventory are stored until usage in the packaging or in the dressing case in which they are sterilized, in conditions that exclude their contamination; time of shelf life of auxiliary materials is no more than 3 days. Taking of materials from the dressing case should be done with sterile tweezers, dressing case should be closed tightly.

Narcotic, psychotropic substances, substances of the list A, substances with the established norm of one-time realization (NOTR), substances with the established highest single doses (HSD) and the highest daily doses (HDD) in the prescription are absent.

Pharmaceutical examination of a doctor's prescription

М (Acidi ascorbici) = 0,05 * 10 = 0,5

М (Sacchari) = 0,2 * 10 = 2,0

Мt (total mass of powder mixture) = 2,0 + 0,5 = 2,5

Мw (mass of weighting) = 2,5 / 10 = 0,25

Calculations in the passport of writing control

When choosing a scales we are guided by the rule: the weighted mass must be placed in the interval between the minimum and maximum limits of weighting, respectively, you can choose the scales-5 as its MinLW = 0,1 g, MaxLW = 5,0 g.

Choice of mortar and scales.Choice of mortar and scales. Weighing of the substance for pharmaceutical use.

When choosing a mortar, we follow the rule: the total mass of the powder mixture should be close to the optimal loading of the mortar and should not exceed the maximum loading of the mortar, respectively, choose the mortar № 4 (table #6.1.2.-1.) and a pestle of appropriate size.

To mash the pores of the mortar and pestle, choose saccharum (since it is an excipient), add 2.0 to the mortar, grind

When mixing, follow the rule: the ratio of the components to be mixed should not exceed 1:5. In our case, the ratio is 1:4, so we weight 0,5 of acidi ascorbici with the scales-5, place it to the mortar, grind and mix

Grinding and mixing

check the powder mixture for homogeneity (presses the head of the pestle into powder mixture – it should be uniform in appearance) and flow characteristics (pour from the capsule to the another capsule, the powder mixture should be granular, should not clumping).

Interim quality control

On scales -1 (MinLW = 0,02 g, MaxLW = 1,0 g) we weight 0,25 No.10 in simple paper capsules (primary packing) using celluloid scraper or «scoop», wrap capsules and stack in a cardboard box or paper package (secondary packing).

Dosing

We make out and glue the label

Mark

Microbiological quality control

In our case, it can be carried out selectively according to the index "Microbiological purity", carried out by testing laboratories

Chemical quality control

In our case it can be carried out selectively on the “Identification” index. It is carried out by a pharmacist, as well as by specialists from testing laboratories. The results of chemical quality control are reflected in the journals

Physical quality control

Verification of compliance of the total mass or volume of the drug, the number and weight of individual doses of the drug, specified in the prescription or requirement. Medicines are went through this control selectively (in our case, not less than 3% of the whole number of powders compounded during the day). The results of physical control are fixed in the PWC.

“The mass of individual doses and their number”, deviation ±10% (0,25± 0,025), number of doses – 10

Organoleptic quality control

Checking of appearance of the drug, its color, smell, homogeneity of mixing components. All medicines manufactured in pharmacies are went through this control. The results are reflected in the PWC

homogeneous white powder

Written quality control

All medicines manufactured in pharmacies are went through this control. PWC is being filled in by the pharmaceutical worker who has prepared this medicine. It is carried out right after finishing of compounding in accordance to the order of technological stages

Evaluation of the quality of the manufactured dosage form