arabera Никита Шакирзянов 3 years ago

128

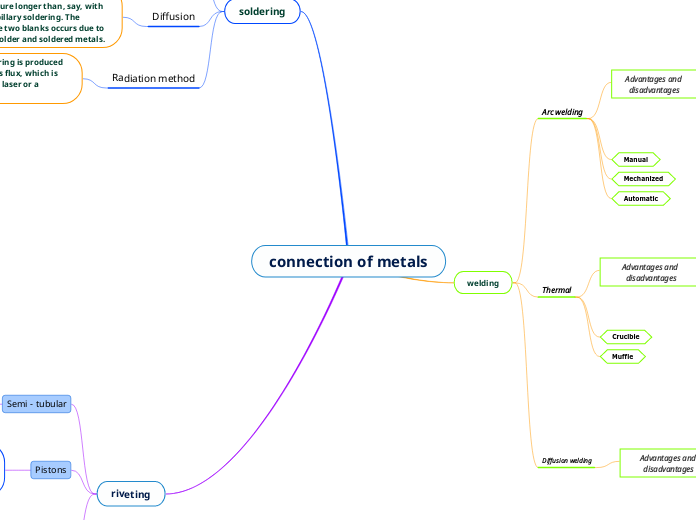

connection of metals

Various methods are used for connecting metals, each with unique advantages and disadvantages. Thermal welding ensures strong joints with minimal metal consumption and low labor intensity, but it is limited to metals with similar refractoriness and can have surface irregularities.