a Wagner Lacerda 9 éve

224

GSB_PROJECT_BODY

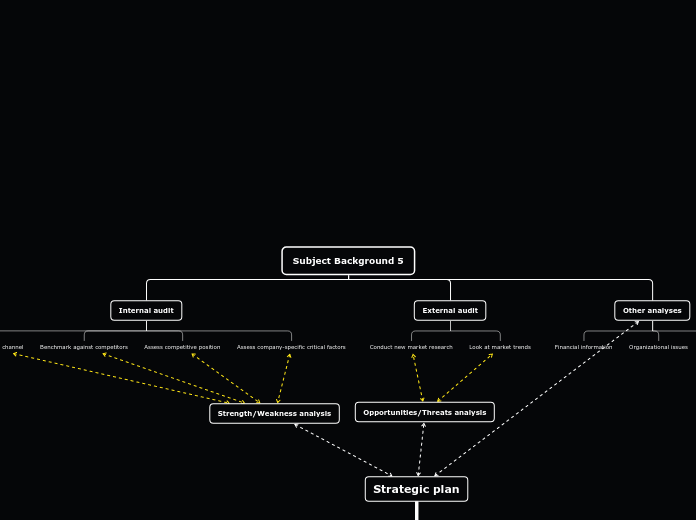

The text outlines various quality control and inspection processes within a manufacturing or assembly environment. It highlights the importance of welding classifications and the effectiveness of sealers, hemming, and mastics.