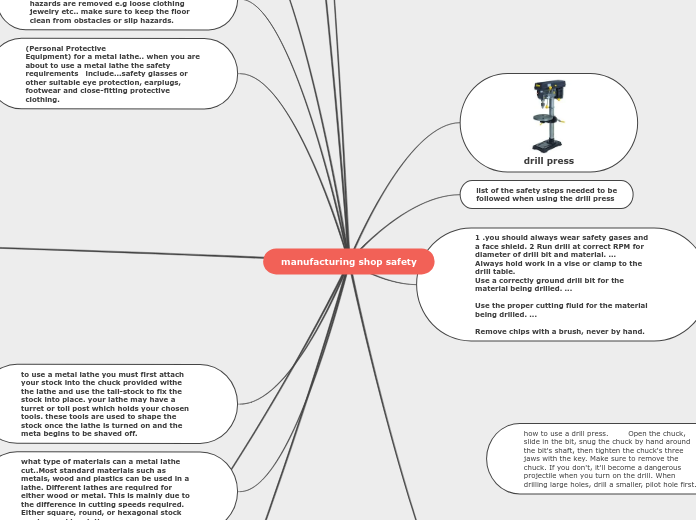

how to use a drill press. Open the chuck, slide in the bit, snug the chuck by hand around the bit's shaft, then tighten the chuck's three jaws with the key. Make sure to remove the chuck. If you don't, it'll become a dangerous projectile when you turn on the drill. When drilling large holes, drill a smaller, pilot hole first.

(Personal Protective

Equipment) for drill press -glasses / face shield, hearing protection, proper footwear (closed toe / heal shoes). Remove all jewelry; loose clothing and tie back hair. DO NOT wear gloves when operating the drill press.

what type of material can a drill press drill it can drill such as wood, and metal.

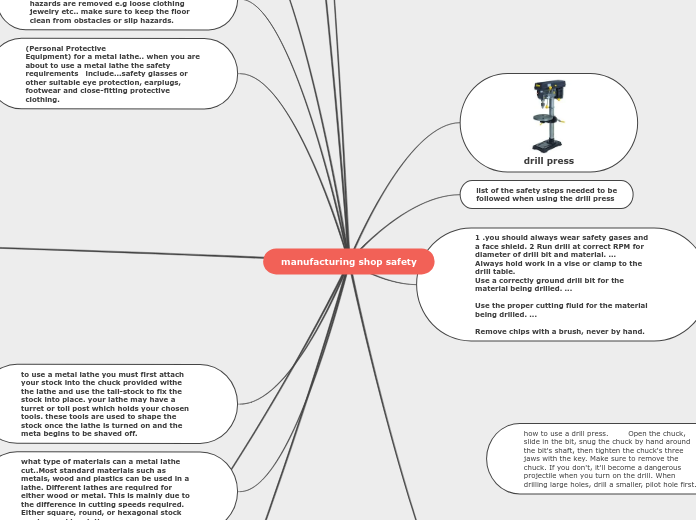

manufacturing shop safety

Various Hand Tools

most of these tools can cut wood .

Point sharp tools (e.g., saws, chisels, knives) laying on benches away from aisles and handles should not extend over the edge of the bench top. Maintain tools carefully. Keep them clean and dry, and store them properly after each use. Carry tools in a sturdy tool box to and from the worksite.

personal protective equipment's when using hand tools...Eye and face protection, such as safety glasses, safety goggles, safety side shields, face shields and laser welding shields;

Hand protection, such as gloves and barrier creams;

Head protection, such as hard hats;

Hearing protection, such as earplugs and ear muffs.

A list of the safety steps needed to be when using various hand tools... you should always wear eye protection. always Follow the correct procedure for using EVERY too so you will be more safe when using these tools. dont work with oily and greasy hands because it can slip out of your hands and hit you. never carry tools in your pocket because it can fall down and hurt you.DON’T use tools which are LOOSE or CRACKED.DON’T pry or hammer with a FILE. It may shatter.DON’T use screwdrivers as chisels or pry bars.

Subtopic

general shop safety

you should wear all these personal protective equipment when entering a general shop... Protective gloves.

Hearing protection.

Full face shields when cutting, grinding, or chipping.

Chemical splash goggles.

Respiratory protection.

Fall protection equipment when working above 6 feet.

A list of the safety steps needed to be when entering a shop... you should never smoke in a shop. keep the work area clean and organized. you should wear protective gear at all times.you should remind all customers to wear safety gears when entering the shop that the customers will be safe and the shop as well.

what type of materials can a metal lathe cut..Most standard materials such as metals, wood and plastics can be used in a lathe. Different lathes are required for either wood or metal. This is mainly due to the difference in cutting speeds required. Either square, round, or hexagonal stock can be used in a lathe.

to use a metal lathe you must first attach your stock into the chuck provided withe the lathe and use the tail-stock to fix the stock into place. your lathe may have a turret or toll post which holds your chosen tools. these tools are used to shape the stock once the lathe is turned on and the meta begins to be shaved off.

band saw

the materials that this tool can cut is wood.

how to use a band saw ... basically a band saw is just what it sounds like its a big looping blade thats passing along two wheels the blade is working down into the table the cutting half is down into the table there are couple of settings you need to have set up before you can use your band saw. you have to have proper tension on the blade before using it you also have to set guide bearings so that they control the lateral and side to side lateral and backward movement of the blade so once these are setup you are ready to use the band saw. one of the main things you do before making any cuts is you have to adjust the height

Wear safety glasses or goggles, or a face shield (with safety glasses or goggles). Wear hearing protection that is suitable for the level and frequency of the noise you are exposed to in the woodworking area. Wear protective footwear when required.

Adjust the height of your blade guard to ⅛ “- 1⁄4” above your material, as this reduces the risk of blade breaks tension A list of the safety steps needed to be when using a band saw .. the first thing you should do is to not wear gloves while using a band saw because the gloves will give a flase sense of security and do very little to protect your hands in fact they may end up getting your fingers pulled into the blade if the material catches it Wear protective footwear when required. Wear safety glasses or goggles, or a face shield (with safety glasses or goggles).

Wear hearing protection that is suitable for the level and frequency of the noise you are exposed to in the woodworking area.

(Personal Protective

Equipment) for a metal lathe.. when you are about to use a metal lathe the safety requirements include...safety glasses or other suitable eye protection, earplugs, footwear and close-fitting protective clothing.

safety steps needed to be when using the metal lathe... you should wear proper csa certified glasses. make sure involve-mental hazards are removed e.g loose clothing jewelry etc.. make sure to keep the floor clean from obstacles or slip hazards.

metal lathe

Vertical Mill

materials that vertical mill cuts...Common materials that are used in milling include the following:

Aluminum.

Brass.

Magnesium.

Nickel.

Steel.

Thermoset plastics.

Titanium.

Zinc.

how to use the vertical mills, the spindle axis is vertically oriented. Milling cutters are held in the spindle and rotate on its axis. Typically the spindle can be extended, or the table raised or lowered to produce the same effect, allowing for plunge cuts and drilling

(Personal Protective

Equipment) for vertical mill... you should Wear appropriate CSA-certified safety glasses. you should Wear other personal protective equipment as necessary (such as footwear or hearing protection).

a list of safety steps needed to be when using the vertical mill... the surface of the machine should be clear of sraps, tools and materials. you should remove cutting tools from spindle when you are cleaning the machine. the milling machine should be free of oil and grease.

cnc router

The materials that the cnc router can cut of materials like steel,wood, aluminum, composites, plastic, and foam.

Procedure on how to use the cnc router...comes with the ability to use computer numerical control to route tool paths that enable the machine to function. CNC routers reduce waste and increase productivity, producing various items in a much shorter amount of time than using other machines.

(Personal Protective

Equipment) for cnc router... Always wear safety glasses and hearing protection when operating CNC machines. Always wear safety glasses when closely observing cutting tools. Always wear safety boots or other suitable footwear. Always keep long hair covered when operating CNC machines.

list of the safety steps needed to be

followed when using the cnc router. you should never wear gloves while using the cnc machine.You should never wear jewelry or any loose clothing.You should never try to reach into the machine while it's running.

welding

Some of the best metals for welding include:

Low Carbon Mild Steel.

Aluminum.

Stainless Steel.

Other Metals.

. safety steps needed when welding..... always wear proper face mask.

ALWAYS wear close-toed shoes.

ALWAYS wear a long-sleeved, non-flammable shirt.

ALWAYS wear proper welding gloves.

ALWAYS wear ear protection (earplugs or muffs) to prevent sparks from entering your ear canal.

personal protective equipment's for welding..

Welding - Personal Protective Equipment

Body Part Equipment

Eyes and face Welding helmet, hand shield, or goggles

Lungs (breathing) Respirators

Exposed skin (other than feet, hands, and head) Fire/Flame resistant clothing and aprons

there are many types of weldeings and i chose mig wild..The MIG welding machine will have a ground clamp that will complete the electrical circuit between the welder, the welding gun, and the metals being welded. Apart from this, make sure you go through the welder manual thoroughly.

MIG welding is ideal for thicker metals, but you’ll need to manage the voltage properly to avoid burning through the metal, creating metal lumps, or having your metal oxidize.

Make sure that the welder of the gas tank has the right mix of gases at an ideal pressure, and you’re good to go.

1 .you should always wear safety gases and a face shield. 2 Run drill at correct RPM for diameter of drill bit and material. ...

Always hold work in a vise or clamp to the drill table.

Use a correctly ground drill bit for the material being drilled. ...

Use the proper cutting fluid for the material being drilled. ...

Remove chips with a brush, never by hand.

list of the safety steps needed to be

followed when using the drill press

drill press