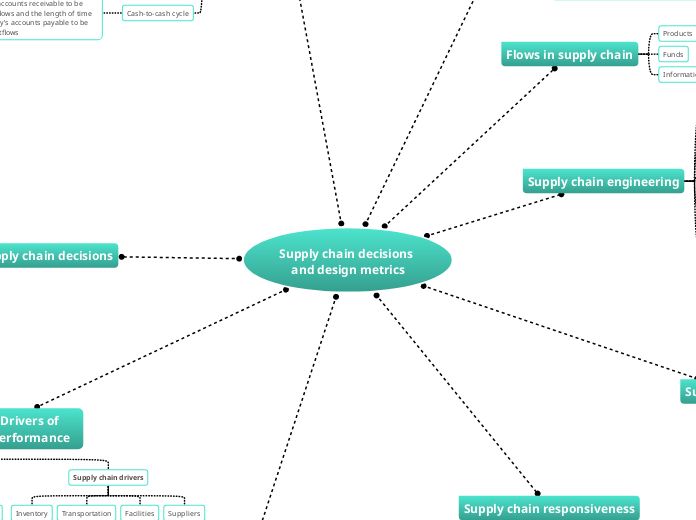

Supply chain decisions

and design metrics

Supply chain efficiency

A supply chain that requires less cost input to generate the same amount of sales revenue output is more efficient, this can be measure by:

Inventory levels

Product cycle time

Distribution cost

Manufacturing cost

Raw materials cost

Enablers and Drivers of Supply Chain Performance

Supply chain drivers

Suppliers

Facilities

Transportation

Inventory

Supply chain enablers

Human resources

Alliances

Technology

Organizational infrastructure

Supply chain decisions

Operational Decisions

Are short-term decisions made on a daily/ weekly basis,

Allocating limited supply

Generating weekly or daily production schedules

Setting due dates for customer orders

Setting delivery schedules for shipments from suppliers

Tactical Decisions

Are primarily supply chain planning decisions and

are made in a time horizon of moderate length.

Distribution decisions

Transportation decisions

Inventory management decisions

Production planning decisions

Purchasing decisions

Strategic Decisions

Strategic decisions deal primarily with the design of the supply chain network and the selection of partners, long term.

Information technology

Production and sourcing

Network design

Supply chain metrics

Cash-to-cash cycle

refers to the difference in the length of time it

takes for a company’s accounts receivable to be converted into cash inflows and the length of time it takes for the company’s accounts payable to be converted into cash outflows

Working capital

is the difference between a company’s short-term

assets and its shortterm liabilities

Return on assets

Refers to the ratio of company’s net income to its

total assets

Return on Assets (ROA) =Annual income ($)/Total assets ($)

Inventory capital

refers to the total investment in inventory

Inventory capital =

N

∑IkVk

k=1

Ik = average inventory of item k

Vk = value of item k per unit

N = total number of items held in inventory

Days of inventory

refers to how many days of customer demand is

carried in inventory

Days of inventory= Average inventory/Daily sales

Inventory turns

Is a measure of how quickly inventory is turned

over from production to sales

Inventory turns=Annual sales/Average inventory

Supply chain responsiveness

refers to the extent to which customer needs and expectations are met, and also the extent to which the supply chain can flexibly accommodate changes in these needs and expectations.

Percentage of customer demand filled from finished goods inventory versus built to order from raw materials or component inventories

Time to process special or unique customer requests

Product variety

Delivery time

Reliability and accuracy of fulfilling customer orders

Supply chain risk

Operational risk

these are more commonly occurring disruptions

whose impacts are localized and resolved over a relatively short period of time.

Hazard risk

these are disruptions to the supply chain that arise

from large-scale events with broad geographic impacts

Supply chain engineering

Managing the integrity of the supply chain network by mitigating supply chain disruptions at all levels.

Management of the transportation and logistics network to deliver the final products to the warehouses and retailers

Management of the production and inventory of finished goods to meet customer demands

Procurement of raw materials and parts from suppliers to the manufacturing plants

Design of the supply chain network, namely, the location of plants, DCs, warehouses, and so on

Flows in supply chain

Information

Funds

Products

Supply chain

A coordinated set of activities concerned with the procurement of raw materials, production of intermediate and finished products, and the

distribution of these products to customers within and external to the chain