American Health and Medical Products

(AHMP)

Chapter Supplement: Process Mapping and Analysis

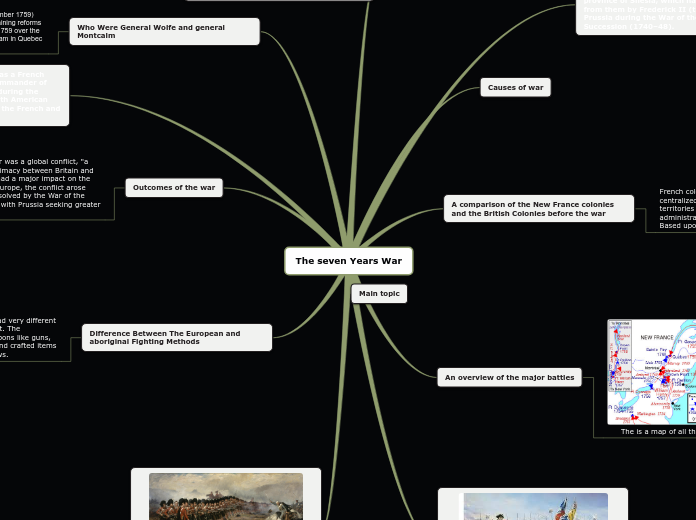

Other Processing Mapping Tools

Service Blueprinting

Value Stream Mapping

Process Flow Diagramming

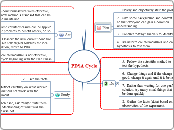

The Process of Process Mapping and Analysis

Implement the changes and monitor improvements

Recommend appropriate changes to the process

(the "future state" map)

Applying in AHMP:

Process Summary Table for AHMP

a process redesign

(Future state process flow table for AHMP)

Three basic categories

3. Determine that the change is not ultimately desirable or feasible

2. Postpone the change until sufficient resources or capabilities become available

1. Make the change immadiately

Analyse the process and identify oportunities for improvement

Future State Process Flow Table for AHMP

Principles of process improvement

Repositioning

Disposing

Eliminate

Rethink

Combine

Keep

Assessment-Mapping Value

Question mark

Waste-generating activity

Necessary but not value-adding activity

Value-adding activity

Document the existing process (the "current state" map)

Three basic charting

3. Process summary table

2. Physical layout diagram

1. Process flow table

General guidelines that can make this task simpler and easier to manage:

3. Watch out for hidden steps in a process

2. Use different process mapping and analysis techniques

1. Identify minimum acceptable levels of detail

Process Activity Types

Identify and bound the critical process

AHMP: in this case, the critical process is order entry (a shared process). The process starts with the receipt of the order and it ends when the order has entered production scheduling.

a critical process typically exhibits at least

one of following traits :

7. It is the location of the problems/issues of concern to the firm

6. It is a process that is related to a unique skill or core competency

5. It is exhibits the greatest level of variance

4. It is a shared process

3. It consumes the largest amount of resources

2. It is visible to the customer

1. It is bottleneck process

Determine the desired outcome for the process and the associated metrics needed to evaluate its performance

AHMP: to maximize the percentage of orders going through order entry that are completed within one week from the time that they are received, with 95% being an acceptable level of performance

Using metric to evaluate the

performance of the process

should clearly reflect these

desired outcomes