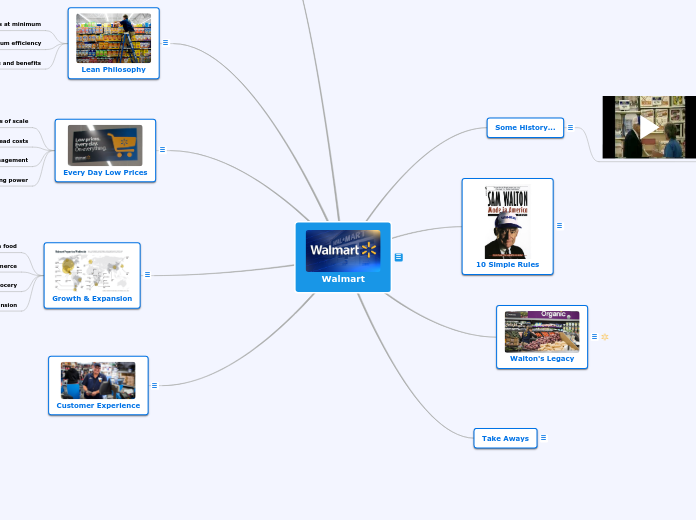

Walmart

Walmart - World's Biggest Discount Retailer

Not only Walmart is one of the most successful retailers around the world, but also one of the greatest companies when it comes to O&SCM. With 11700 stores in 27 different countries, 2.2 millions employees and 32$ billions inventory, efficiency is key. Their offer ranges from groceries to sportswear, to satisfy every possible need of their cliente base. With the aim of providing its customers whatever they need, wherever they need it, the company's focus has been on having the most effective cost structure to deliver every day low prices (EDLP).

Why Walmart?

I think Walmart represents a great example of excellent O&SCM. Moreover, the company has applied the concepts studied in class in an outstanding way, among the different topics I was particularly amazed by the pricing strategy, inventory management, lean operations and growth strategy. I think studying this company should be essential in all management courses and gaining deeper knowledge about its way to conduct operations can be useful for our future jobs. Its values of efficiency and commitment made Walmart standout in the retailer landscape since its origins.

Customer Experience

Walmart's image

I still remember when I lived in Boston going to Walmart was not only to buy merchandise, it was an essential part of every Bostonian. It was a family activity, a moment to get together. Walmart managed to create an image, as brand close to the people and close to the families that helps them solving their problems at the lowest cost.

Constantly improving customer experience

Many new services are constantly introduced to improve customers experience. Among the newest adds:

- Check out with me (personnel located in the busiest areas for fast check outs)

- Walmart app

- Store maps on the app

- New online experience

- More merchandise for free two-days shipping

- Broadest assortment

Growth & Expansion

3 Years Growth Plan

- First retailer to deliver a seamless shopping experience at scale

- Easy and fast purchasing process with a combination of in-store, online and mobile

- Sales expected to increase by approximately 45$ - 60$ B

- Deepening digital relationships with customers

- Next generation supply chain

5 Growth Areas

- VALUE: Price leadership / Private brands

- CONVENIENCE: E-commerce, online grocery, smaller formats

- MERCHANTS: Natural & organic food, health & wellness

- GEOGRAPHY: North America and China

- APPEALING: Fresh food/Online grocery/ E-commerce

Forward looking strategy!

Global expansion

Online grocery

E-commerce

Fresh food

Every Day Low Prices

EDLP

When the value of the item is huge, it produces less sales, and when the price is little, it decreases revenue. Discovering a suitable price for a product is crucial to business accomplishment.

WalMart 's ability to provide customers with "everyday low prices" and its presence as an economic and political force of gigantic size and influence, is the result of a process that was built on some core principles and procedures. Looking at Walmart's history and present operations helps investors understand the methodology that enables this sizeable chain to do what it's known to do best – sell cheap.

What's worth noting, though, is that this model – built on low prices, on a large scale, at minimal cost – was never changed, but instead gained momentum, building on each success, resulting in an ever-wider spread of operations and constantly increasing leverage for this retail entity, which would in turn use the power gained to acquire even more clout and to provide even lower prices, at an even larger scale, at even less cost to itself.

Walmart continues to offer very low prices, and this is possible due to (1) its huge volume of sales that's possible due to the spread of its operation and its wide customer base, (2) a supply chain management

system that maximizes efficiencies and reduces outlays, (3) minimization of overhead and operational costs, and (4) leveraging of its bargaining power to force suppliers to lower prices.

Bargaining power

Supply chain management

Minimum overhead costs

Economies of scale

Take Aways

Walmart is the perfect example of how much strategy matters to stand out in an industry, and in order to correctly pursue a strategy having an effective O&SC management is key.

Thanks to its logistics and lean operations, Walmart manages to offer Every Day Low Prices while keeping its customers satisfied. Moreover, the company is always up to date with the latest technologies, which allows it to keep pursuing its cost advantage.

Its founder's legacy is kept alive in an outstanding manner, with Walmart closing the fiscal year of 2018 with 500.3$ billion revenues and nearly 265 million customers.

Walton's Legacy

The Legacy

Sam Walton died in 1992, but his legacy lives on. To this day, Walmart remains a leader in the retail industry. We are committed not just to expanding the business to better serve our customers, but also to improving the communities we serve through our efforts to constantly improve what we do and how we do it, and through the impacts we're able to achieve through the Walmart Foundation.

Sustainability

Our approach accelerates us towards our three aspirational goals: to create zero waste, operate with 100% renewable energy and sell products that sustain our resources and the environment.

Community

Walmart and Walmart Foundation are committed to strengthen local community cohesion and resilience while inspiring our associates to give back. Among the different initiatives: disaster relief, hunger relief, support to veterans families and community support.

10 Simple Rules

Sam's Walton believed there are 10 simple rules to run a successful business:

- Commit to your business

- Share your profits with all your associates and treat them as partners

- Motivate your partners

- Communicate everything you possibly can to your partners

- Appreciate everything your associates do for the business

- Celebrate your success

- Listen to everyone in your company

- Exceed your customers’ expectations

- Control your expenses better than your competition

- Swim upstream

Some History...

How it all started

When Sam Walton opened his first Walmart in 1962 the discount retailing business model had been around for a few years. During the 1950s a few companies started applying the supermarket model to the sale of general goods. Walton decided to open his own, but it's what he did differently that made Walmart so successful.

Walmart vs Its Competitors

Walton decided to serve a different group of customers with a different type of merchandise. All its competitors were locating in big metropolitan areas and were selling private label goods, while doing price promotions every now and then. Walmart instead was located in small towns areas, hence discouraging other competitors to enter its small market, and was offering national brands at every day low prices.

Efficiency is key

In order to successfully reach his goal of offering the lowest possible prices, Walmart managed to achieve efficiency while lowering costs and improving logistics.

Lean Philosophy

Lean Operations

Initially designed in the automotive industry of Japan Toyota, the lean concept has been applied to other processes in which they aim at cost savings. Introducing lean operations in the retail sector is not an easy task. The lean concept was developed in the manufacturing industry and the service industry was late in applying the strategy (Åhlström 2004, Portioli-Staudacher 2010).

Unlike manufacturing business, retail business can have little time gap between customer purchase and service delivery at stores. It is difficult for retailers to predict the level of customer demand for purchase. Therefore, an integrated approach of marketing and operation well explains how a lean operation system is adopted in the retail industry. EDLP is a key driver for implementing lean operation, and it discusses what retailers should know related to lean transformation as it relates to the whole process of the retail industry to low cost management.

Continuing the model Walton established for a low-cost operation, Walmart still keeps its overhead low. Its executives reportedly fly coach and share hotel rooms with colleagues. Its meager wages and low-benefit healthcare plans which are offered to rank-and-file employees have been publicized and protested against, although it should be noted that the company announced in January 2018 that it would be raising the starting wage to its employees to $11 an hour. The company has even been accused of demanding that hourly workers put in overtime without pay. It has also been said that Walmart staff are expected to keep costs at a minimum, even for heating and cooling of the buildings.

Minimum wages and benefits

Maximum efficiency

Keep costs at minimum

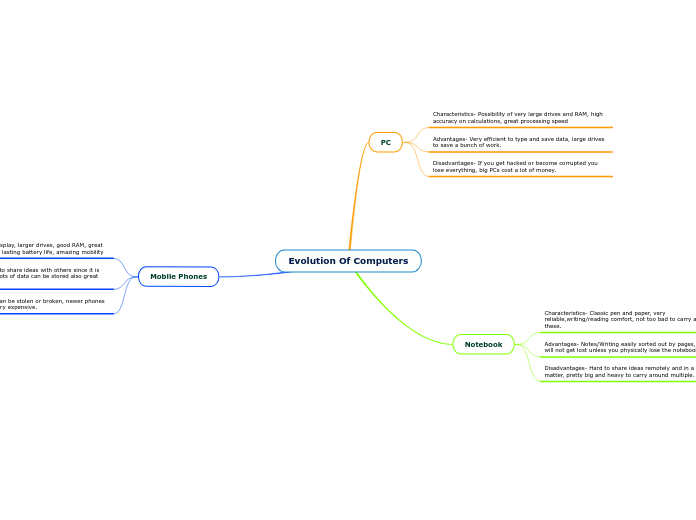

O&SCM Key Elements

Fewer links in the supply chain

Later, in the 1980s, Walmart began working directly with manufacturers to cut costs and more efficiently manage the supply chain. Under a Walmart’s supply chain initiative – called Vendor Managed Inventory (VMI) – manufacturers became responsible for managing their products in Walmart’s warehouses. As a result, Walmart was able to expect close to 100% order fulfillment on merchandise.

Strategic vendor partnership

Finding products at the best price from suppliers who are in a position to ensure they can meet demand. The company then establishes strategic partnerships with most of their vendors, offering them the potential for long-term and high volume purchases in exchange for the lowest possible prices.

Cross-docking

With pure cross-docking, when goods are transferred directly from the receiving dock to the shipping dock, put-away and order picking activities are avoided. Communication and coordination become more important. Around 75 percent of food distribution involves the cross-docking from supplier to customer food stores. Cross-docking keeps inventory and transportation costs down, reduces transportation time, and eliminates inefficiencies.

Advanced inventory technology

Technology plays a key role in Walmart’s supply chain, serving as the foundation of their supply chain strategy. Walmart has the largest information technology infrastructure of any private company in the world, and it is this state-of-the-art technology and network design that allows Walmart to accurately forecast demand, track and

predict inventory levels, create highly efficient transportation routes, manage customer relationships, and service response logistics.

In recent years, Walmart has used radio frequency identification tags (RFID), which use numerical codes that can be scanned from a distance to track pallets of merchandise moving along the supply chain.

Advanced inventory technology

Cross-docking for inventory

Strategic vendor partnership

Fewer links in supply chain