OK ELON, CAN WE STOP FOR A SECOND?

THE BORING COMPANY

THE MIRACLE OF LANDING ROCKETS

Operational Innovation Applied to Rocketry

It is estimated that a Falcon 9 rocket can cost as much as a commercial jumbo jet. But from a cost perspective, the difference is that the latter is not discarded after each intercontinental flight. Why would it be so presumptuous then to think that a rocket should be built for a single use?

Ever since its inception, space shuttles were technically reusable, but its giant fuel tank was discarded after each launch, and the side boosters parachuted after every flight, most of the times landing on sea water, which could be highly corrosive after some time. All of this caused a long process of retrieval and reprocessing. The question that the SpaceX folks made themselves was: could these factors be mitigated by landing rockets precisely? If so, refurbishment time and cost would be dramatically reduced.

The dominating thinking at SpaceX is that low cost, efficiency and simplicity could go hand in hand. They can achieve this by shrinking the number of actors in the supply chain (they have quite a flat organization and they barely rely on subcontractors). This also helps in reducing the times in the supply chain. By internalizing most of the production process, quality control is more effectively applied, guaranteeing shorter design-engineering iterations between teams. Proven designs targeting effectiveness also reduce costs normally associated with complex systems operating at the margin.

So, in essence, we can see that what started as a change in the way the product was used required a complete overhaul of the business’ operations.

NEXT STOP:TRANS-HUMANISM

Neuralink: Overriding the Future

Neuralink, Musk’s new tech venture, wants to change the rules of human-machine interaction. At a basic level, the company wants to build an interface between the human’s mind and AI that could use cloud-stored information as an extension to the brain. The term they are now using, “Neural Lace”, was actually coined by a Scottish Sci-Fi author, Iain M. Banks in its “Culture” novels.

This synthetic bond could upload and download information from the brain. Benefits are immediately seen for topics such as memory functioning, boost cognition and decision making. We are somewhat nowadays already connected with artificial intelligences all day long through our smartphones and computers. It’s just that we would change the channel through which we obtain the information: from clicking or swiping to just thinking about data we want to visualize.

Human brain is probably one of the most complex expressions from nature: its pattern-recognition abilities are still unmatched even by our own creations. What puts us on clear disadvantage with respect to machines is our limited cognitive abilities (“the bandwidth”) by factors such as culture, language, training, etc. The harsh truth is: We lack an optimal interface.

There are several socioeconomic implications to this: information treatment, job performance or communications will be considered in a completely different manner. Such a technology could have positive and not-so bright nuances:

- Removing physical disability as a barrier: From robotic limbs to vision implants, brain interfaces can help solve an unfair differentiator between humans. This will bring people with disabilities more into the mainstream fold, economically and socially.

- Learning will undergo a revolution, while directly input necessary information needed to learn. In a sense, this may remove the value of grades and schools and learning from the system while the overall ability to learn and respond instantly will measure success.

- It will also create new work fields: mind-workers, who could lease their body of knowledge or personal experiences to other institutions via the neural lace.

- Social inequality though may come under a new form: layered pricing could prevent the low-income masses to access more sophisticated knowledge that would pay off better.

- Security: in a world in which every device is interconnected and we are connected into this knowledge mesh, privacy and data security will prevent the wrongdoers from hacking into our system and use the information to their profit.

Now, when you thought it couldn't get any creepier, here's good old Prof. Kaku giving us some examples about the current and future applications of brain-machine interface:

HYPERLOOP: A BULLET TO THE HEART OF OLD LOGISTICS

Just A Fancy Transport or Next-Gen Freight?

Uncertainty today about the achievement of a zero-risk scenario for this revolutionary transport has made its current sponsors to shift the current focus from passenger to freight transport.

The initial vision of connecting far-distant urban areas could be now applied to logistics. Recently revealed designs would show that the pods travelling within the tube would be capable of holding a standard 40-foot intermodal container, including built-in cargo security since it would be operating in a point-to-point secured and dedicated environment – the tube itself.

Hyperloop also has major contribution potential for green supply chains. It is a carbon-free mode of transportation that can also help alleviate traffic congestion on busy highways where trucks produce significant amounts of air pollution. Expected low energy consumption, would also significantly reduce transportation costs.

By connecting two distant metros, Hyperloop One creates a geographical cluster which could help reduce inventory costs, promote even more just-in-time strategies, and expand same-day delivery service areas. And, by extending the effective economic boundary of a city, firms could have better accessibility to manufacturing hubs and retail stores and save travel time.

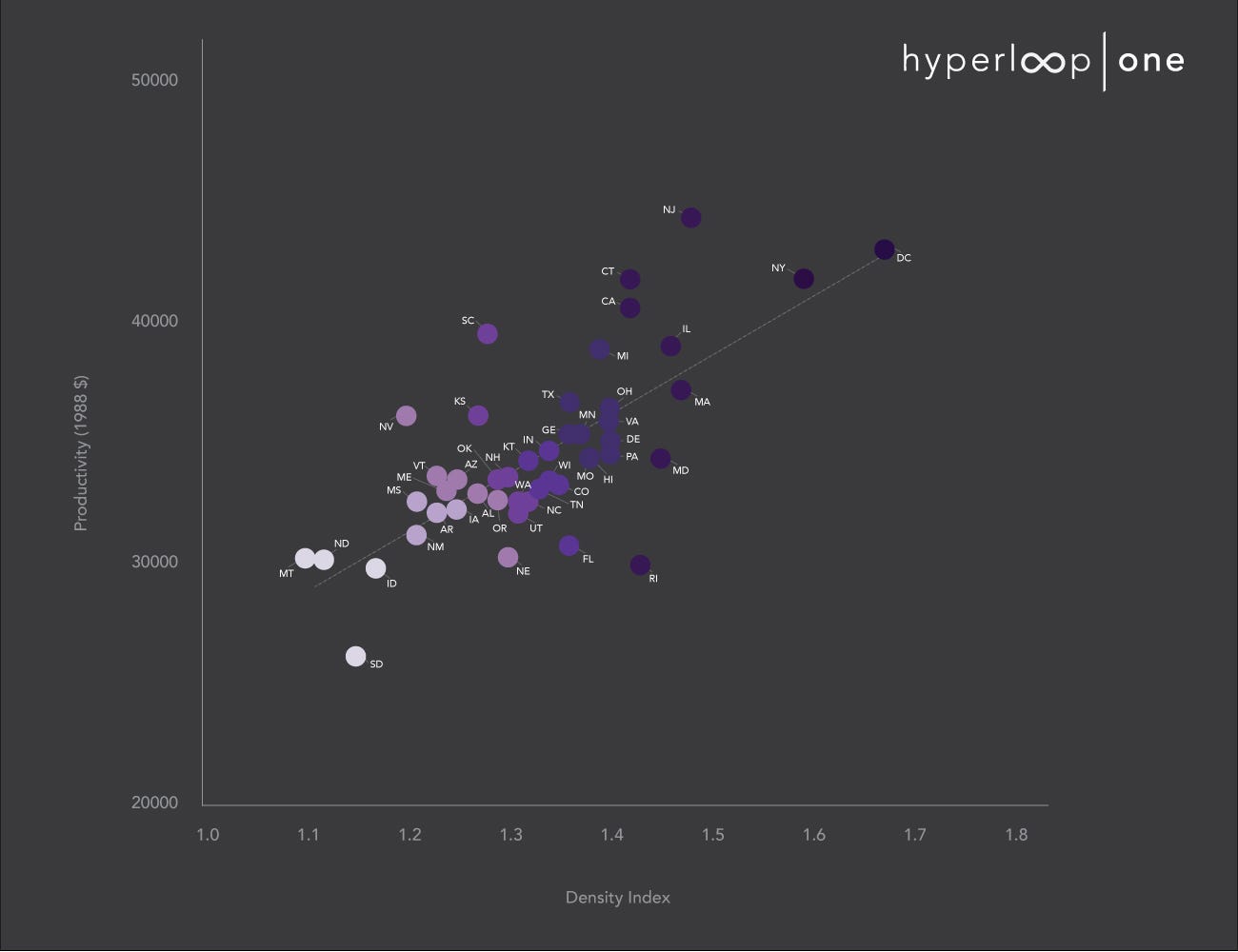

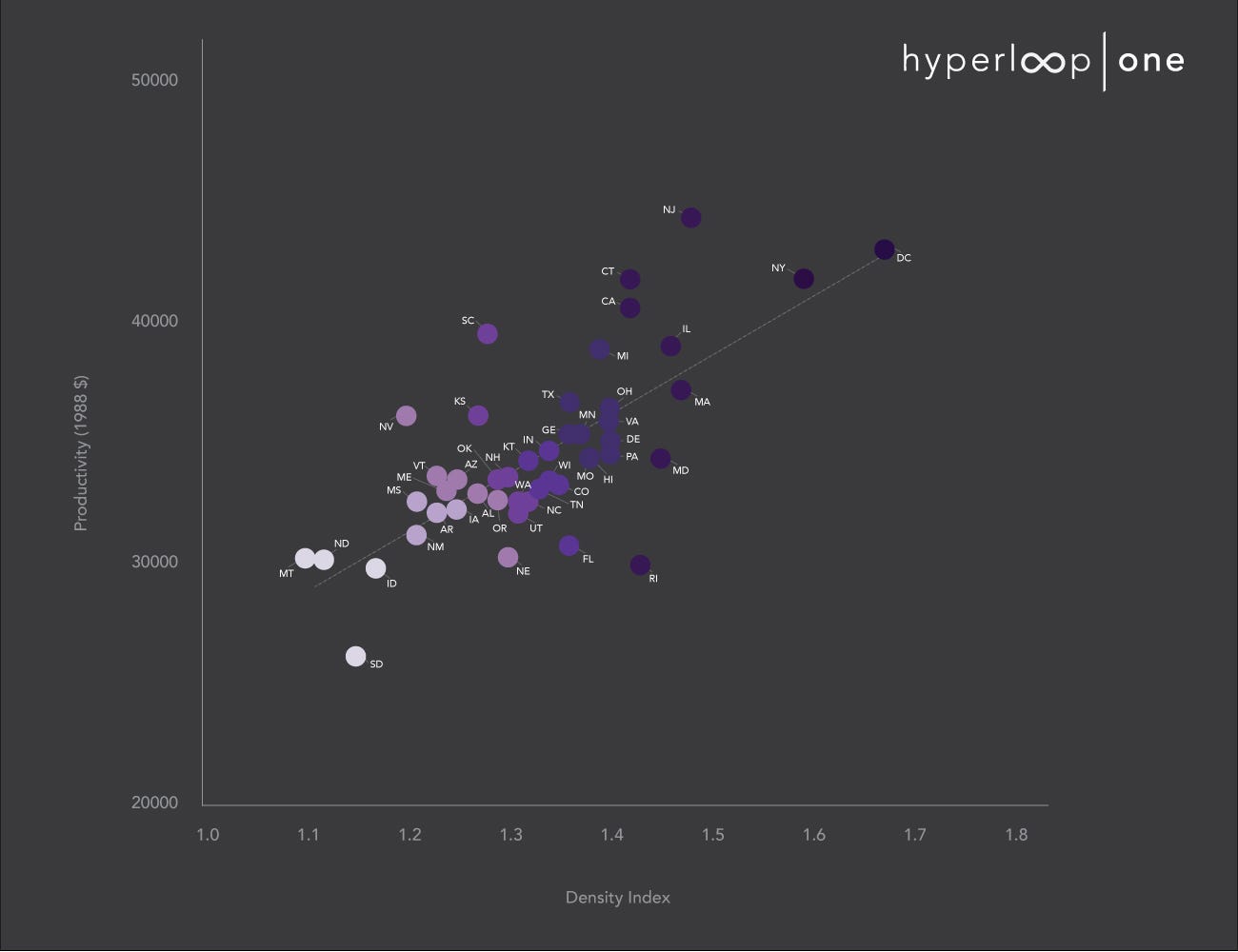

According to a study by Ciccone and Hall in 1993 (see Figure 1 below), targeting the relationship between productivity and urban density in the US at a state level, there is a strong positive correlation between them: Density increases average labor productivity. Hyperloop can contribute to this link by virtually increasing density without the downsides of agglomeration such as traffic, pollution, and vehicle accidents. Time-sensitivity could be another driver to push towards the integration of this new type of transport into global supply chains.

Fig 1. Productivity and Density (Ciccone and Hall, 1993)

WE KNOW FUTURE MIGHT BE BORING AS WELL...

THE FIRST PRINCIPLES

Boiling the s**t out of Analogic Thinking

Quite an impressive résumé, isn’t it? Ok he’s damn smart but, is that all? How can it be that a guy who had hit the jackpot twice right after turning 30, seems to be consistently devoted to go bankrupt by pursuing crazy businesses (saying risky would be an understatement) but nonetheless he always manages to land on his feet? Musk’s apparent recklessness has always been questioned in the last decade as the different businesses never seemed to take off until some government funds arrived or he unlocked some deal with the investors, avoiding a Chapter 11 filling.

However he has publicly stated many times that he is totally confident about the businesses he backs. Can he see things that we can’t? Is he hiding some crystal ball? Well, he calls this ”The First Principles”. As in nature being ruled by physics that will never change regardless of the context, Musk says that every problem should be deconstructed until you find its very foundations, and then start building from there up. He says no one thinks like this on a daily basis because it will be exhausting. We tend to think by analogies, based on our own previous experiences or on what anyone else has done or told you. This is indeed a good and faster way to proceed on a business-as-usual scenario but, whenever you want to come up with something truly innovative, to take a quantum leap, you need to “boil things down to its first principles”.

Here's a video of Elon himself explaining this not-so-obvious framework:

TRANSITIONING TO A CLEANER WORLD: ONE GIGA AT A TIME

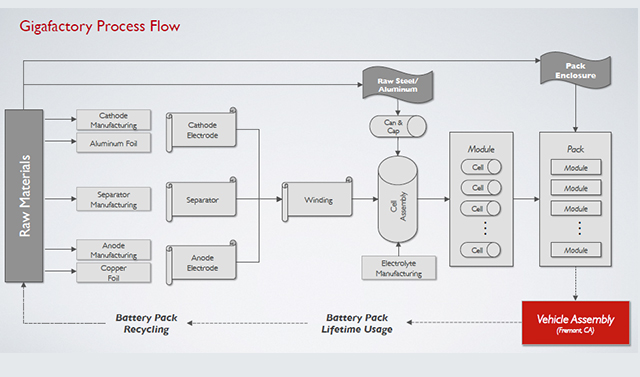

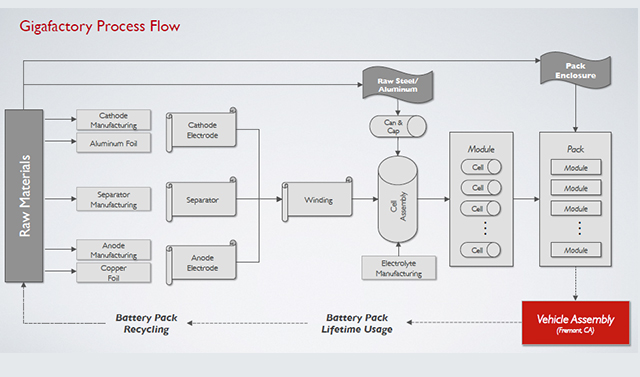

Supply Chain Management at the Gigafactory

Along with Panasonic, its key partner on the EV storage business, and other stakeholders, Tesla has invested more than $5 billion into the Gigafactory, which will eventually cover an area equal to about 100 football fields, one of the largest buildings in the world.

In order to keep lowering costs, Tesla concluded that it could not mimic the design of a traditional battery plant: It would take a full re-design from the ground up. Altogether, the Tesla team believes there are three variables it can control to build a cheaper battery that will outperform its competitors: materials, labor, and factory design.

Tesla’s degree of vertical integration reverses half a century of US manufacturing strategy that has seen most of the supply chain leave the factory, often for overseas. At the Gigafactory, rail lines will ferry ore from Nevada’s lithium mines to the factory, and then ship out finished battery packs to Tesla’s car facility in Fremont, California.

On their side, engineers are trying to recapture as much materials and energy costs as possible. The onsite waste, battery, and water recycling plants will reduce raw material demand. All fossil fuels were eliminated from the manufacturing process, something that would have seen unthinkable just some years ago for such facility. Electricity will come from solar panels covering the factory roof, and on-premises batteries. Renewable power can be bought from the grid as needed, ensuring zero net greenhouse gas emissions.

ELECTRIFYING THE CUSTOMER JOURNEY

Delivering Best Practices in Customer Experience

The auto industry has long been relying on some strict principles according to its value chain: one of them is that the manufacturer takes care of the product and its marketing while leaving the sales and customer service activities to the dealership network. Tesla gets by without engaging this stakeholder because the product does not really require it: they know their customer and what he wants, and selling an EV means that they don’t require as much maintenance as traditional cars do. Instead, through their own retail locations, Tesla wants its customer to use the space to get a better understanding of the brand, to experience it and its philosophy. That is a best practice regarding customer experience.

Whenever a Tesla is sold, at the store or online, the company will deliver the car regardless of the customer’s location. They also offer to pick it up at the factory so they can give the customer a tour around the premises. The Tesla car is more of a technology hub though, serving as a platform with several add-ons which could be remotely updated, overnight for example, removing the need to go to a service center. This is another chance that the company can leverage its brand, by offering extra updates at no cost.

In a nutshell: High performance, careful design, breakthrough innovation, binding consciences around a more responsible behavior towards our environment, this is what the brand stands for:

A SHINY BUSINESS MODEL

The Dawn of Consumer-Scale Solar Power

SolarCity’s business model relies on the steady stream of revenues generated by a long-term Power Purchase Agreement (PPA). It has other sources of income like Leases, but their main driver for growth is obtained through the signing of PPAs with its customers.

Once the contract is signed, the company installs solar panels on the customer’s roof for free. The 20-year contract, which is the typical length of a standard contract, will allow the end-user to acquire the energy at a much lower rate than that of the utility companies. SolarCity will keep the ownership of the asset and service maintenance contracts, while collecting the cash flows in the form of an annuity that the customer pays for the energy it utilizes.

In order to sustain its operations, the company has invested a lot in some of the key components of the business model:

Sales and Marketing: Direct marketing is critical in order to manage a heavy interaction with the customer. SolarCity employs a traditional door-to-door sales force so they can bring a personal touch to customer relationships

Design and Installation: Local teams ensure that the equipment is the right fit for a given household. Based on the house’s dimensions and estimated energy consumption, the design staff draws the solar power system. 24 hours is the estimated timeline for an installation project, after obtaining all the permits and inspections, which SolarCity takes care of.

Manufacturing: Initially, the company purchased the components from external third parties. This fact capped their ability to innovate and improve technology. Through the vertical integration of two of their suppliers, Zep Solar and Silevo, they solved this issue.

Operating Partnerships: After its full acquisition by Tesla Motors last year, SolarCity can further expand on the synergies between both companies. Some of them have been already put in place (the company started a partnership with Tesla Motors’ Powerwall to efficiently manage customer energy use during the day). Currently, a solar panel’s energy covers roughly 70% of the customer’s energy needs, but with more efficient usage this percentage could climb to 100% thereby lowering the customer’s bill and further optimizing the value capture of the business model.

ELON MUSK: FROM SCIENCE-FICTION TO "SCIENCE FACT"

The Billionaire Geek

Electric autonomous vehicles? Rockets that can put stuff into geostationary orbit and return to earth by landing on sea platforms? Shooting people inside pods in a tube connecting cities across continents? What for most of us would be the by-product of drunk bar talks, there is but one man who is building an empire out of these revolutionary ideas: Meet Elon Musk, The Real-Life Tony Stark

KEY TAKEAWAYS

What Have I Learned So Far?

I would like to use this lines to summarize what this course has meant to me and which are the lessons I can take with me for the rest of the journey lying ahead:

- Whenever we are building a new business line, project, activity or process within our organizations, we need to understand to what extent will they have an impact on the final/product or service and, if such impact will add or destroy any value to our customer. Customer satisfaction should be the ultimate metric any business should pursue regardless of their strategy.

- Sometimes your strategy, when it’s not being thought thoroughly enough, can lead to problems in the operational level. Such was the case of the Al-Kadi company, in which, looking once more for maximum customer satisfaction, ended up with product portfolio/stock management and excessive centralization.

- Lean philosophy can only work out in an organization whenever there is some flexibility between standardization of processes but enough openness to allow creativity. Silos only contribute to the extent of their own improvement not for the organization as a whole, so these should be removed without jeopardizing the value chain. Finally, the business must be sincerely committed to hear and understand the voice of the customer, whether it is internal or external.

- In addition to the latter, it is important to remark that, for true alignment to be met amongst the different areas of the business; all the areas should create opportunities to work on common projects regardless of their business line. Some good opportunities are: review of compensation system, meeting periodically with your HR business partner, design team-building outdoor activities or arrange roundtables with management and other areas.

- Even if it’s sequentially done, rather than a one-off transformation, Product Development cannot be a process that turns its back to market requirements. Companies must open themselves to allow different iterations that balance time-to-market vs time-to-perfection processes so they can be constantly aligned with the customer needs.

- I’m glad also that, by picking this topic on Elon Musk and its businesses, I came across with this First Principles approach. Whenever we are dealing with a problem, it is good to apply frameworks like the “Ishikawa Diagram” in order to discern the root causes of a problem. It will help us in tearing down old paradigms that restrain innovation or progress.

HOW ON EARTH HE DOES ALL OF THIS?

THE BUSINESS AS USUAL

HE WANTS TO GIVE US A RIDE TO THE FUTURE