por moses mothibe 1 ano atrás

89

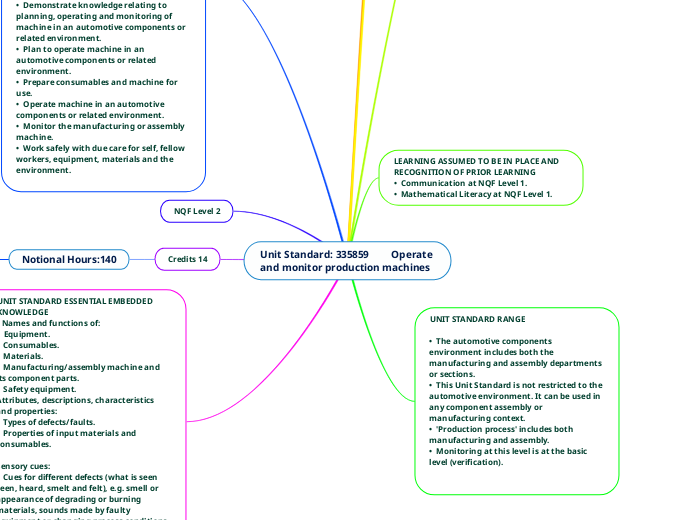

Unit Standard: 335859 Operate and monitor production machines

Ensuring that machines and consumables are properly prepared and operational is crucial in any production environment. This involves conducting thorough pre-operational checks to identify and resolve issues before commencing the production process.