arabera Dan Richter 11 years ago

245

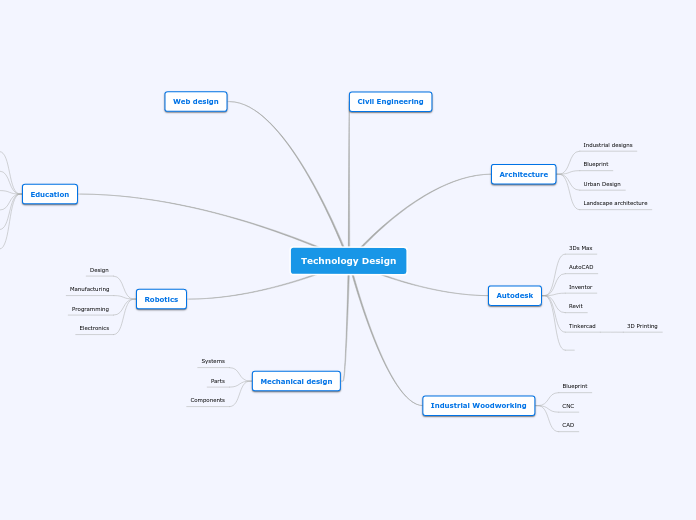

Central topic

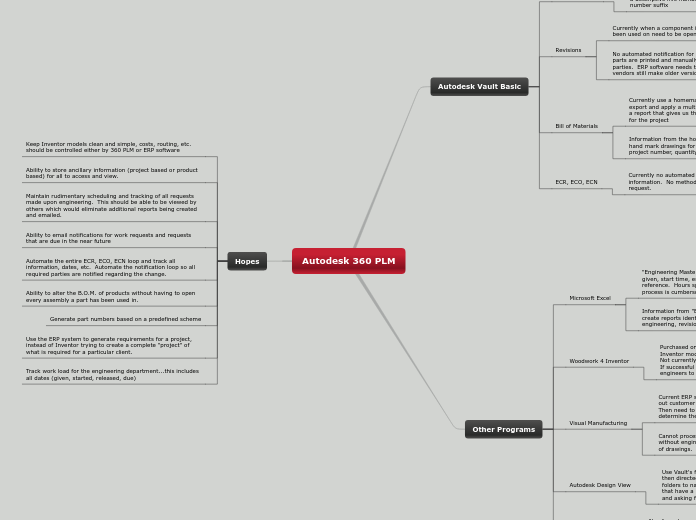

The organization utilizes various software tools to streamline its engineering and production processes. Autodesk 360 PLM and Autodesk Design View are used to create and manage visualization files centrally, allowing easy access without needing physical copies.