por AYLEEN MELISSA GAVIRIA GUTI€RREZ 4 anos atrás

199

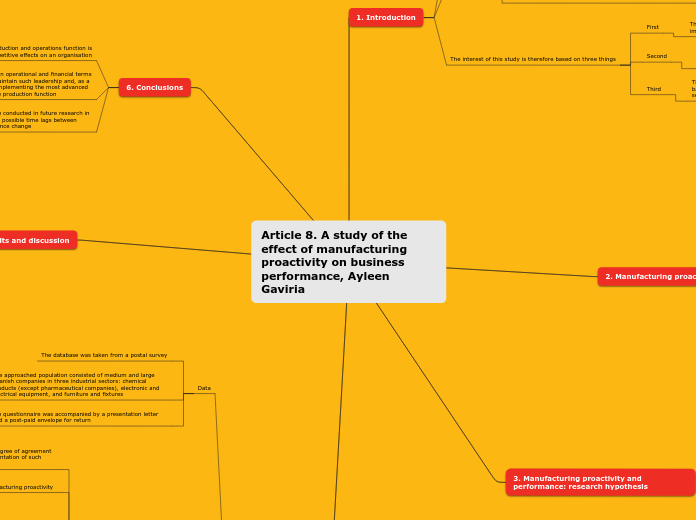

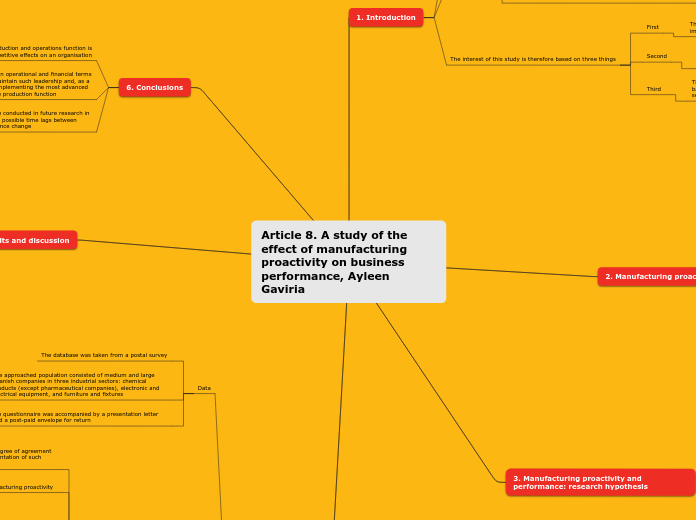

Article 8. A study of the effect of manufacturing proactivity on business performance, Ayleen Gaviria

por AYLEEN MELISSA GAVIRIA GUTI€RREZ 4 anos atrás

199

Mais informações

The industrial sector – which required the introduction of two binary variables distinguishing the chemical and electronic and electrical equipment sectors, respectively

The electronic sector concentrates the largest companies with the newest equipment and the highest levels of technical proactivity

Company internationalisation – included by using a binary variable distinguishing those companies which are part of multinational groups

The companies belonging to international groups tend to be the larger and more proactive companies

Plant equipment age – measured by the number of five-year intervals from the acquisition of the main productive equipment in use

Company size – measured as hundreds of employees

Managers marked on a five-point scale whether they considered their companies very inferior

Very superior

Somewhat superior

Equivalent

Somewhat inferior

Very inferior

In the Varimax orthogonal rotation

The second factor

mainly takes in practices that involve the adoption of concrete tools or techniques in the production plant as

JIT systems characterises those companies with high scores on factor 2

advanced manufacturing technologies

integrated information systems

CAD/CAM systems

It measures a technical dimension

The first factor

It implies a greater cultural change within the organisation and a high score on this factor means

that the company thinks of employees as resources instead of costs, considers their suppliers as collaborators rather than competitors, and promotes dynamism and continuous improvement

It measures a cultural dimension of manufacturing proactivity

The underlying manufacturing proactivity

It was performed, which capture 49.498 percent of the variance

each company was asked to choose their degree of agreement with ten assertions referring to the implementation of such practices

Manufacturing proactivity, involvement of the production function in strategic processes, and alignment between production capabilities and strategic objectives

Hayes and Wheelwright (1984) distinguish four stages in the evolution of manufacturing’s strategic role

In stage IV, externally supportive, the production function constitutes a fundamental mainstay of the business strategy and is involved in major strategic decisions topic

Those companies showing a higher degree of production proactivity are probably in stage IV or close to this stage. In fact, in what can be interpreted as production proactivity

In stage III, internally supportive, a production strategy is developed in order to support the business strategy

In stage II, externally neutral, some modifications are introduced in the production function in order to, at least, not harm the business strategy

In stage I, internally neutral, the production function is considered as a necessary burden that is difficult to change

Advanced manufacturing practices and business performance

The implementation of innovative work practices

involvement through problem-solving teams

employee participation

include employee training

It is through the literature

the degree of commitment to a long-term programme of investments in manufacturing structure and infrastructure aimed at building capabilities in anticipation of their need.

the degree of involvement of manufacturing in the strategic processes of the business unit

This research combines subjective measures of performance based on perceptions with objective data obtained from secondary sources.

This paper raises different causal explanations of the relationship between manufacturing proactivity and performance

The paper explores the behavioural dimensions underlying the implementation of advanced production practices